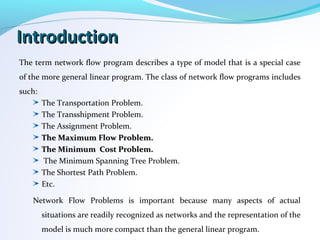

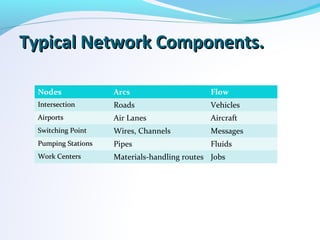

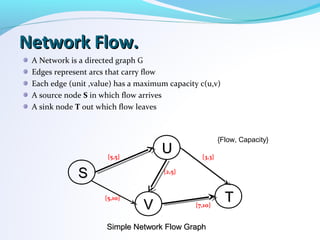

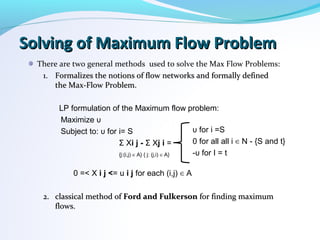

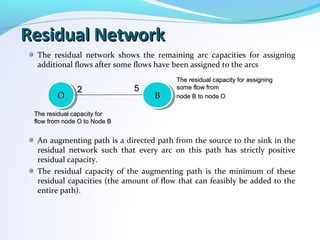

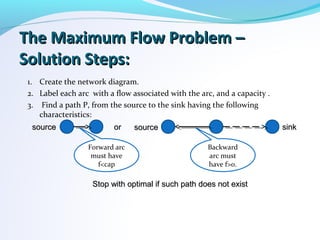

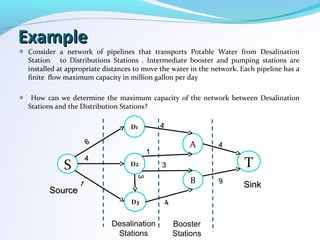

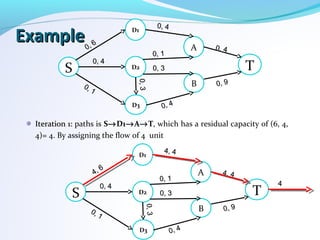

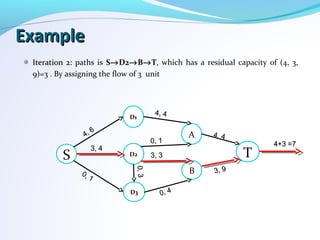

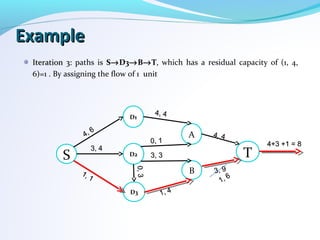

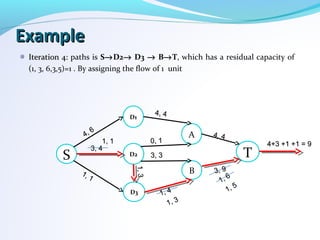

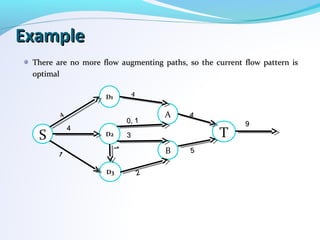

The lecture outline discusses network models and network flow problems. It introduces key concepts like the maximum flow problem and minimum cost flow problem. It provides examples of solving the maximum flow problem using the Ford-Fulkerson method and concepts like residual networks and augmenting paths. The document also provides a sample problem solving the maximum flow problem on a network transporting water.