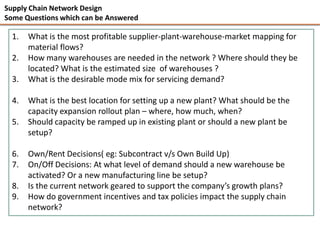

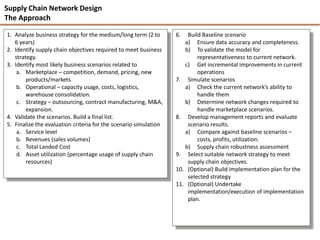

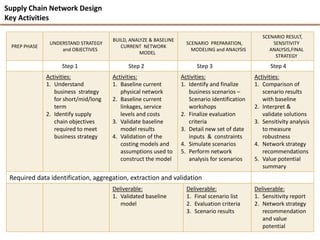

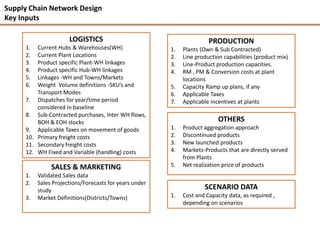

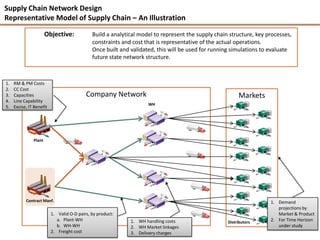

Supply Chain Network Design is a strategic exercise to evaluate and recommend changes to a company's physical supply chain, including inbound and outbound movement and storage of raw materials and finished goods. It aims to optimize asset utilization, total landed costs, and service levels to improve margins. Key triggers for a network design study include changes in regulations, business environment, growth plans, new products/markets, and mergers. The study analyzes scenarios to determine the most profitable supplier-plant-warehouse-market mapping and answers questions about facilities, capacity, and transportation.