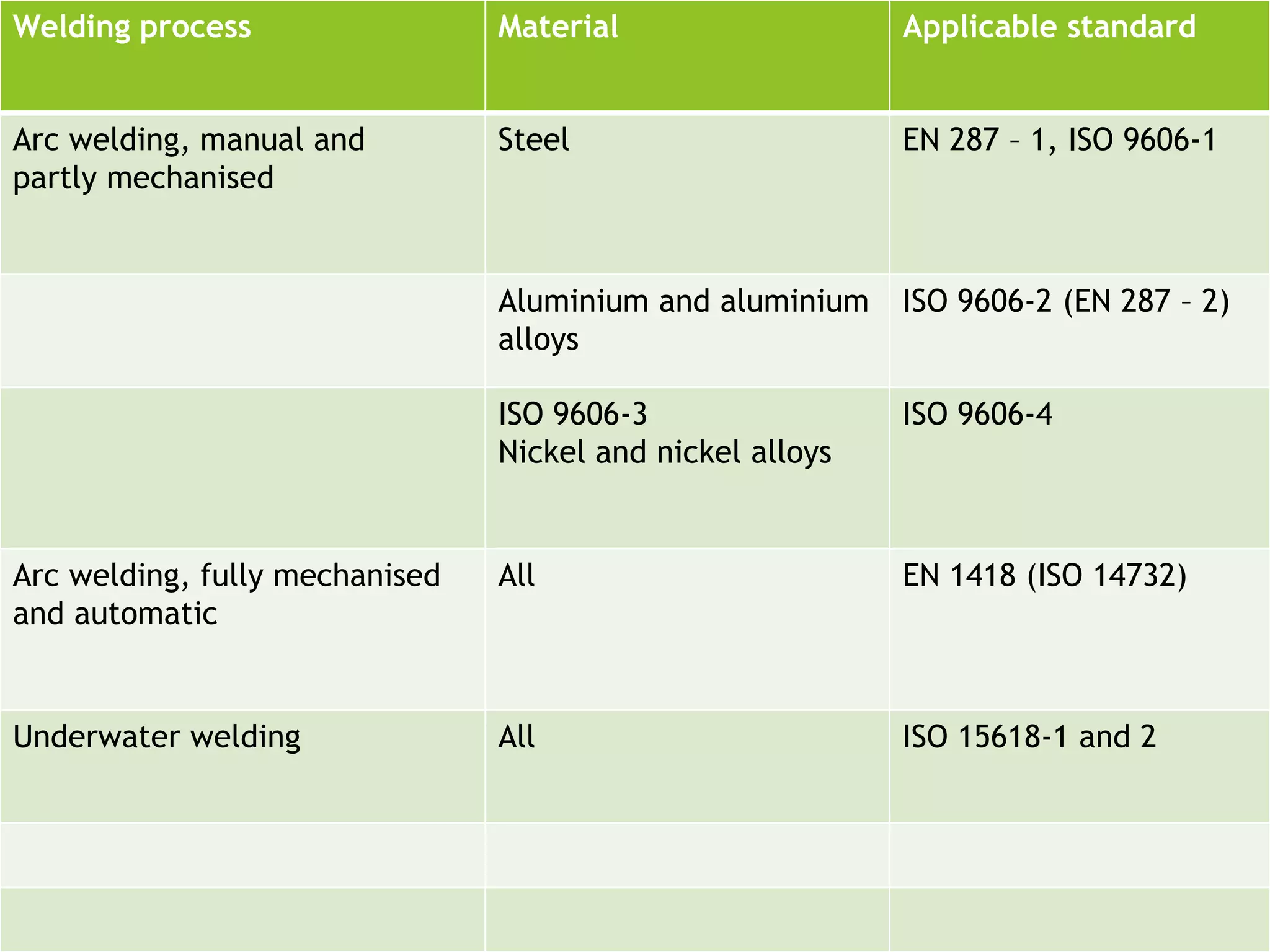

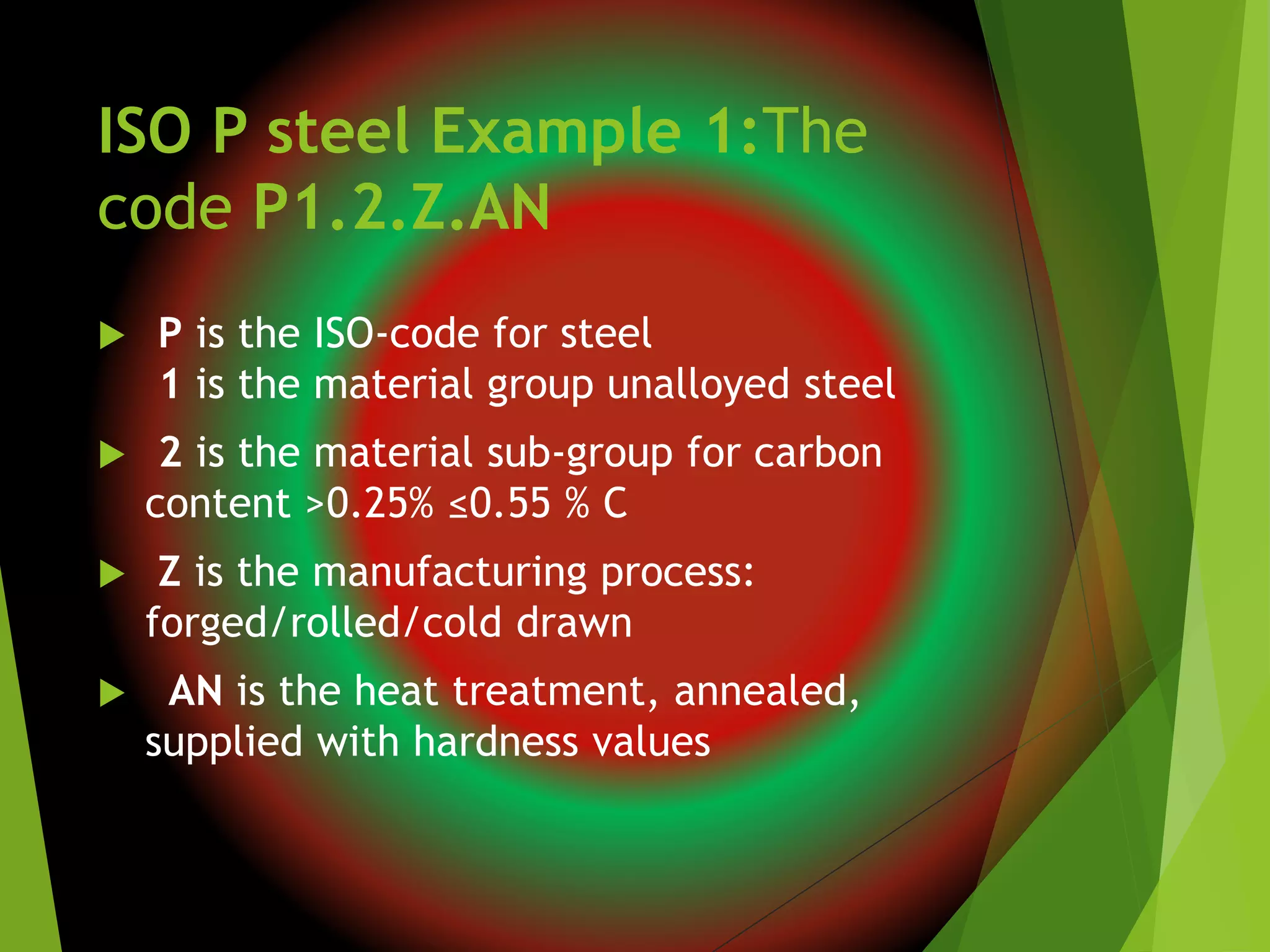

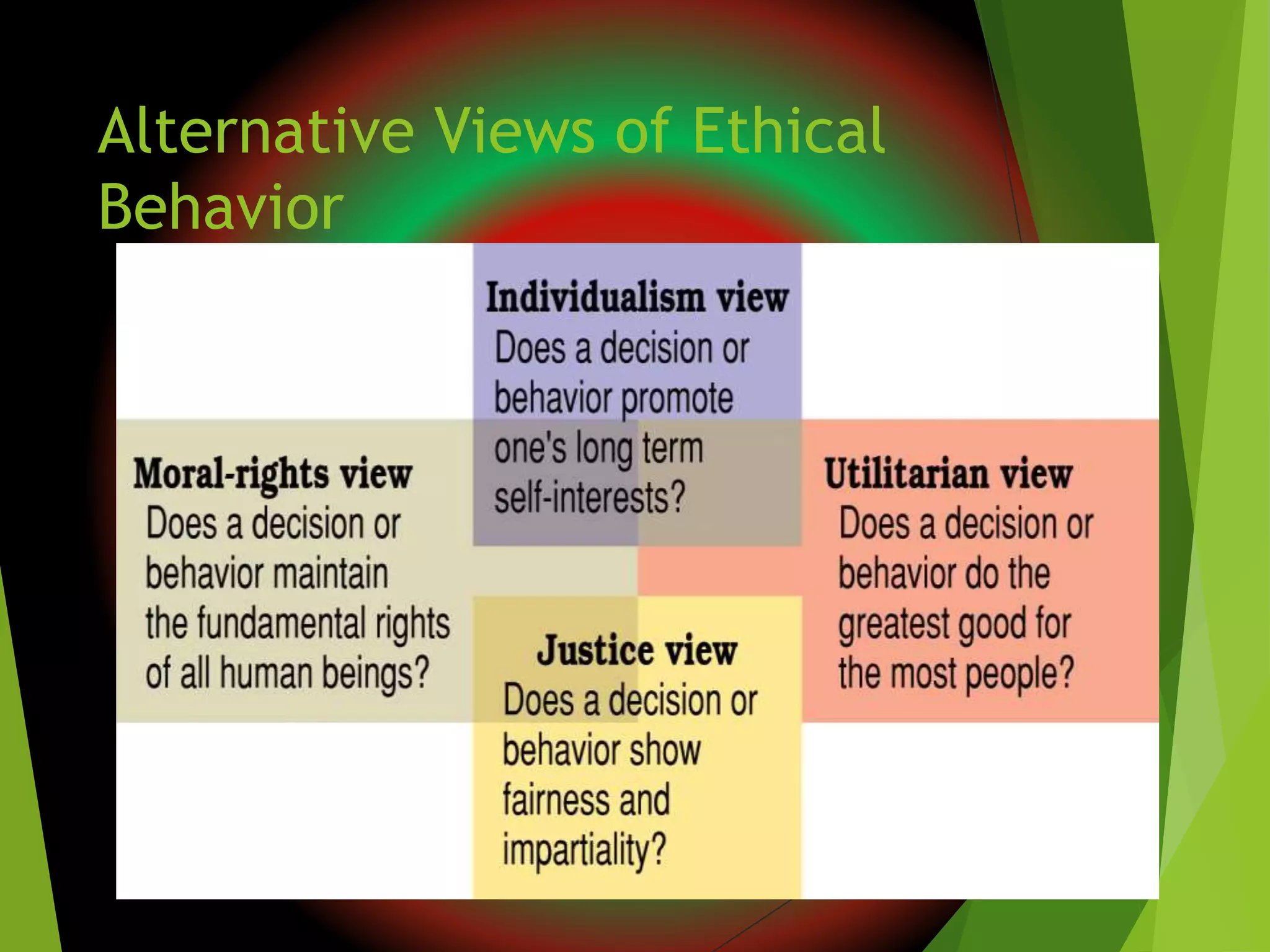

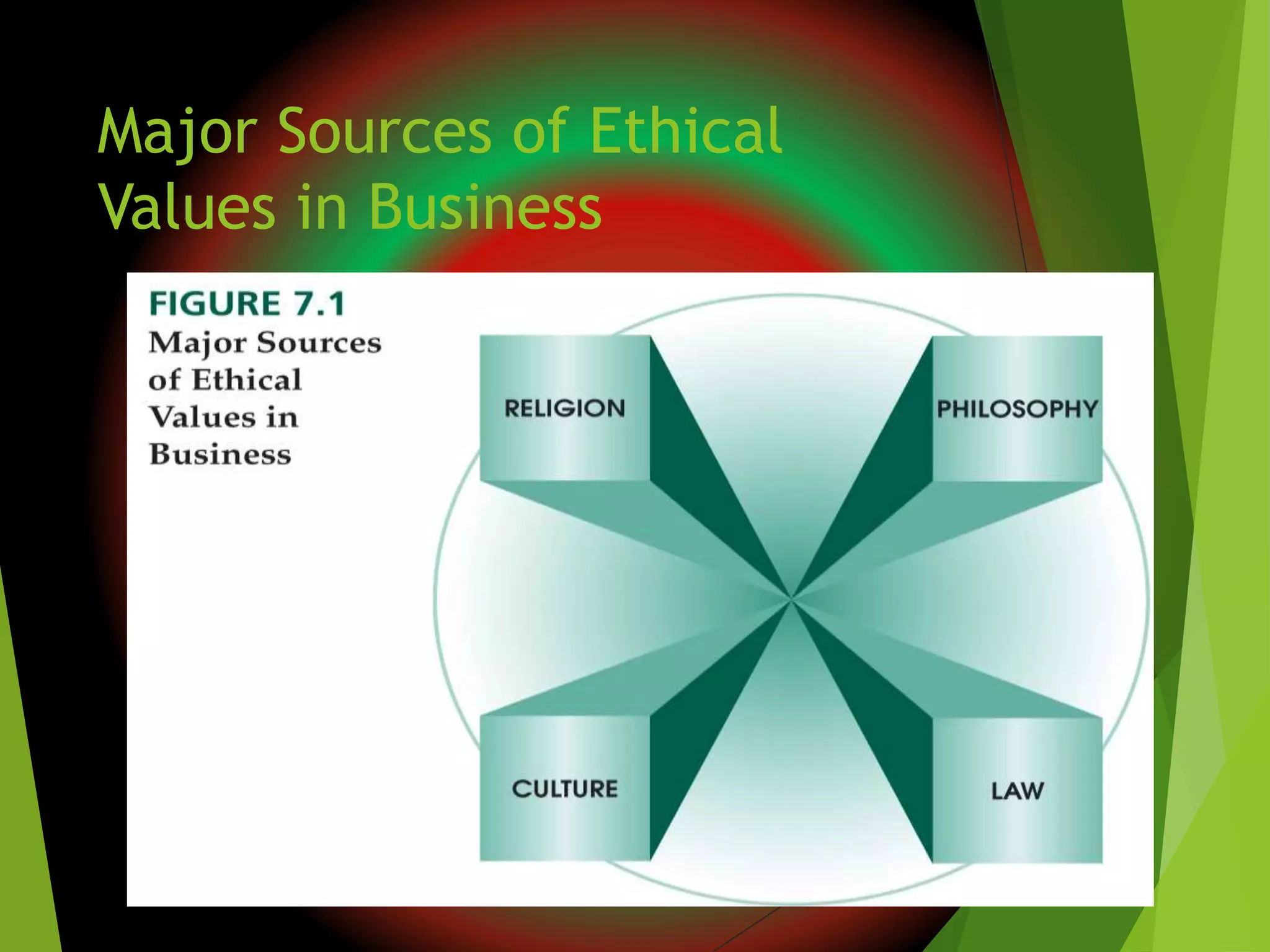

The document outlines standards and codes in various domains, detailing their definitions, types, and specifications, such as ISO standards for quality and environmental management. It explains the concept of codes as standards enforceable by law, and provides detailed classifications for materials under ISO codes. Additionally, the document covers ethical behavior in organizations, offering insights on maintaining ethical standards and addressing dilemmas in the workplace.