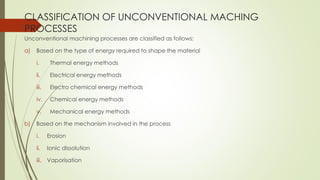

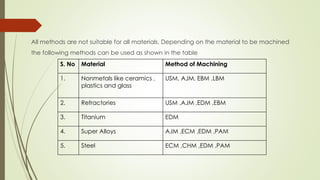

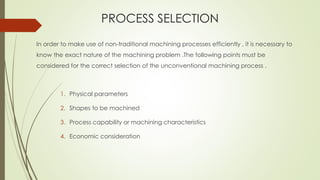

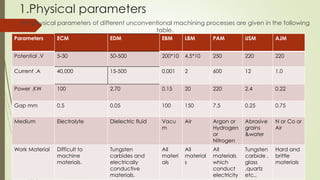

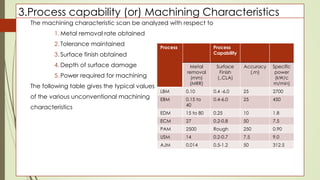

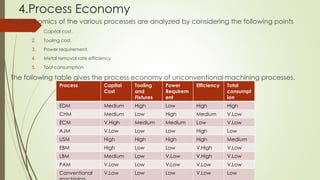

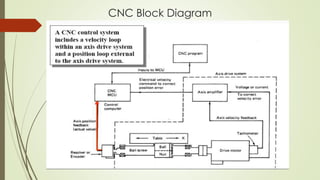

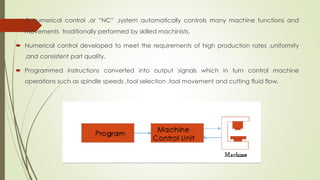

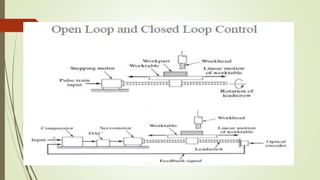

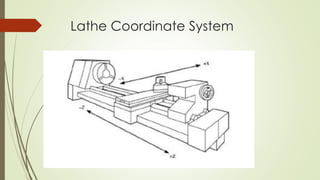

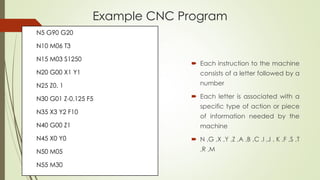

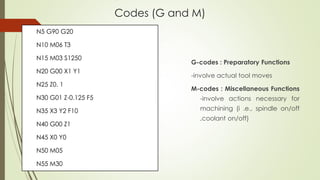

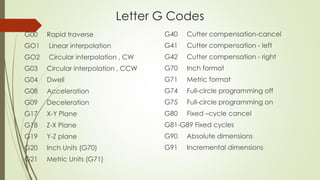

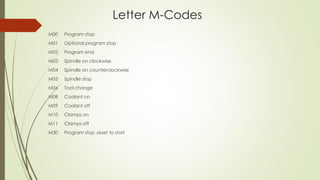

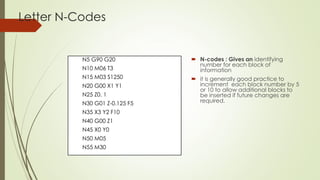

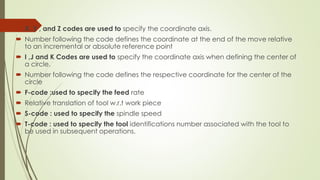

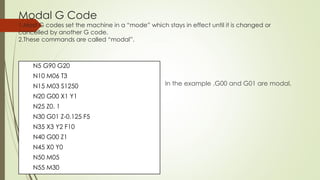

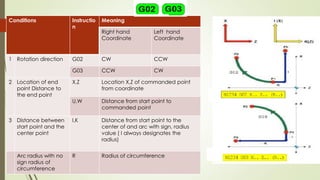

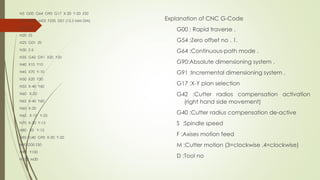

The document discusses conventional and unconventional machining processes. Conventional machining involves direct contact between the tool and workpiece and removal of metal through chip formation, which produces chips as waste. Unconventional processes do not require direct contact and instead use various forms of energy like thermal, electrical or electrochemical to remove metal. Common unconventional processes described include EDM, ECM, laser beam machining and water jet machining. The document also covers CNC machines and how part programs control automated machining through coded G and M commands.