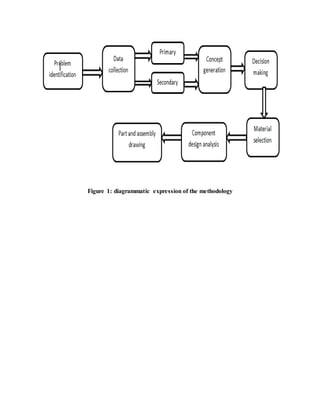

The document describes the design of a solar-powered sheet metal bending machine. It notes that existing manually operated sheet metal bending machines at Adigrat University pose safety risks. The objectives of the new design are to develop components, select materials, and create drawings using Solidworks. The methodology follows a PDD sequence, including problem identification, data collection from observations and interviews, design analysis, and cost estimation. Materials are selected based on availability, suitability for working conditions, and cost, with cast iron, mild steel, and stainless steel chosen for components like gears, rollers, housing, and screws.