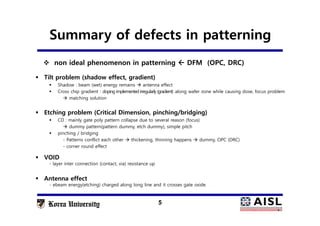

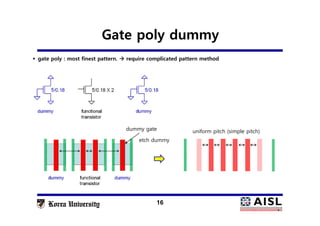

The document is a comprehensive guide focused on high-speed CMOS IC layout techniques, including lithography defects, layout techniques, and high-speed layout guidelines. It addresses common issues in semiconductor design such as matching, loading, reliability, and offers solutions to mitigate lithography-related errors. The content is structured into three main parts: lithography defects and their prevention, layout optimization techniques, and a checklist for high-speed design considerations.

![6

Figure 2: pinching and bridging during manufactureFigure 1: Process variation band.

Figure 4: Bridging failure.Figure 3: pinching failure.

process variability bands / bridging, pinching

hotspot (Critical Dimension) Error (next page)

pattern defect examples [1]](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-6-320.jpg)

![7

gate-poly defect (Critical Dimension) example

thickening, thinning, pinching and ... all GP defects

closely related with circuit performance degradation.

thickening, thinning, pinching and ... all GP defects

closely related with circuit performance degradation.

gate-poly pattern defects (CD) [2]](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-7-320.jpg)

![9

charge dissipation

@active on the bulk

charge dissipation

@active on the bulk

++++

++++

++++

Plasma damage - Antenna effect [4]

e-beam energy charged by plasma

along antennas (long metal lines)

at high resistance / capacitance burst out.

e-beam energy charged by plasma

along antennas (long metal lines)

at high resistance / capacitance burst out.

+++

+

++

e-beam

(by plasma)

energy charged along

surface of shadow region](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-9-320.jpg)

![10

. charging

. damage

Qbd : 1~100 coulomb/cm2

(breakdown chage )

MOS transistor with positive bias on the gate

electrons that can hop over or tunnel through the oxide-

semiconductor barrier can travel through the oxide.

Electric fields are high, and the electrons can gather

energy and do damage (break bonds) as they proceed.

plasma damage [3]](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-10-320.jpg)

![11

From Automated hot-spot fixing system applied to the metal layers of 65-nm logic devices

@ Journal of Micro/Nanolithography, MEMS, and MOEMS

Defect correction method [5]](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-11-320.jpg)

![Parasitic loading effects [6]

18

phase delay θd and gain |G|

3) Capacitance Cp in Fig. 3(b) represents the parasitic capacitance Cpw with a wire line in Fig 3(a),

and also includes the input parasitic capacitances of the following stage in Fig. 2.

4) Furthermore, the parasitic resistance Rp with the wireline is connected to the output node.

Gain degraded by α (Cp, Rp)](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-18-320.jpg)

![21

• shift placed (differential pair shifted)

• Process variations are averaged among transistors (good dc condition)

• good matching technique for dc condition

• total drain area uneven between M1 and M2. drain capacitance uneven

(not desirable ac conditions: capacitance, other parameters may not be equal)

• A more robust approach is needed (Use dummies if needed !!)

Inter-digitized Layout [7]

M1:KP1+KP4+KP5+KP8 (Avg=4.5)

M2:KP2+KP3+KP6+KP7 (Avg=4.5)

Samuel Palermo

concept and example of inter-digitized layout

good for DC conditioned schematic](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-21-320.jpg)

![22

• Each transistor is split in four equal parts interleaved in two by two’s.

So that for one pair of pieces of the same transistor we have currents flowing in opposite direction.

• Transistors have the same source and drain area and perimeters, but this topology is more susceptible

to gradients (not common centroid)

Inter-digitized Layout (2) [7]

improved Inter-digitized Layout – capacitive matched !

shift placed (not mirrored) gradient not cancelled, but good for DC/AC conditions

Samuel Palermo](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-22-320.jpg)

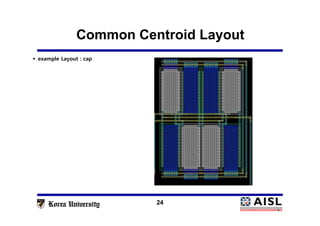

![23

Common Centroid Layout [7]

• split in even for parallel connection mirror placed (differential pair mirrored)

• good for RF application

(less effective of crosstalk mismatch, junction capacitance mismatch)

M1M2M2M1M1M2M2M1

M1M2M2M1M1M2M2M1

M2M1M1M2M2M1M1M2

Samuel Palermo

Common Centroid Layout

Inter-digitized Layout](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-23-320.jpg)

![capacitance – loading [9]

29

Dan Clein

Fringe cap : self loading cap

Process gets narrow, metal stacks

higher Fringe cap higher

Fringe cap : self loading cap

Process gets narrow, metal stacks

higher Fringe cap higher Coupling cap : planar, 3D Coupling cap : planar, 3D

Coupling cap with

Coupled with metals every

where with substrate coupling

effects

Coupling cap with

Coupled with metals every

where with substrate coupling

effects

Coupling cases](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-29-320.jpg)

![30

capacitance – coupling (Crosstalk) [9]

Bottom capacitance Cb

mutual capacitances Cm

Top capacitances Ct added

Dan Clein

Coupling loading through parasitic capacitance of long running metal lines affects seriously on

signal normally tR, tF

It happens not only planar but also 3D. The Tops and Bottoms

M1](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-30-320.jpg)

![capacitance – signal line shield [9]

31

< Differential pair twisting to reduce signal coupling (PCB technique) >

effect of coupling - DC signal shield effect of coupling - DC signal shield

aggressor

victim

aggressor

victim

tPD (delayed)

tPD (normal)

XX : aggressor

. twisted line : coupling noise canceled with differential pair common mode

. shield with vss line.

XX : aggressor

. twisted line : coupling noise canceled with differential pair common mode

. shield with vss line.

Coupling effects : aggressor affects on victim.

Critical signal line could be shielded with static

level signal. This technique will eliminate the

worse-case coupling scenario

Coupling effects : aggressor affects on victim.

Critical signal line could be shielded with static

level signal. This technique will eliminate the

worse-case coupling scenario

effect of coupling - diff pair twist shield effect of coupling - diff pair twist shield

case 1 case 2

. twisted line

. differential pair

. twisted line

. differential pair

XX : aggressor

1

2

1

2

. twisted line, differential pair

. vss shield

. twisted line, differential pair

. vss shield

Dan Clein

Coupling : Victim and Aggressor cases](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-31-320.jpg)

![capacitance – Vref line shield [9]

33

< Shielding option examples in two-metal process >

shield form all way if it needs shield form all way if it needs

Cc_lower

Cc_upper

Vref line

VSS

VSS

• case : isolating the signal from influences on the same layer both sides

• case : isolating the signal from influences on the same layer and upper/lower layers

• case : isolating the signal from influences on the same layer both sides

• case : isolating the signal from influences on the same layer and upper/lower layers

• Voltage reference level is critical to comparator and buffer.

• Reference level could be corrupted by signal line toggling.

• So keep reference line safe as isolate it from signal lines everywhere

• Voltage reference level is critical to comparator and buffer.

• Reference level could be corrupted by signal line toggling.

• So keep reference line safe as isolate it from signal lines everywhere

Dan Clein

Shield : important signal / reference line shielding cases](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-33-320.jpg)

![34

capacitance – Vref line shield [9]

< Shielding option examples in three-metal process >

Dan Clein](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-34-320.jpg)

![35

Resistor – (symmetry) [9]

< resistor shielding >< interlaced resistor shielding >

Dan Clein

Shield : line resistor shielding cases

Line resistor is used for small and simple resistor

Line resistor is also used for skew (tPD) matching. This technique is good for multi bit skew aligning.

Line resistor is used for small and simple resistor

Line resistor is also used for skew (tPD) matching. This technique is good for multi bit skew aligning.

A2

A1

A1 A2

A2 is delayed to A1 RC delay added to A1](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-35-320.jpg)

![36

Balanced NAND – input unbalanced [9]Dan Clein

in2

in1

out

Balanced NAND

One of inputs must be closer (or faster) to output than the other.

To prevent unbalanced path, split NMOS fingers and attach all input TRs to output.

In1 is faster than in2

< Conventional NAND > < Balanced NAND >

in2

in1

out

In1 is slower as in2 is](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-36-320.jpg)

![Balanced layout [9]

37

The schematic shown on the right side of Figure 7.20 shows exactly how the schematic is defined for Example 3. Many LVS

layout verification tools have algorithms to recognize NAND gates within the layout. The layout NAND shown in Example 3 is

not often recognized as a NAND and creates discrepancies when compared to a regular schematic NAND. The reason is

that the order of the series connections within the NAND is reversed. Functionally, they are equivalent and in fact balanced.

In this case the schematic must be altered to reflect the correct connectivity in order for the LVS to pass.

Balancing circuits is not always as straightforward. Balancing series devices is more difficult when dealing with more than

two transistors connected in series. Figure 7.21 shows an example of three series gates to illustrate this concept further.

In order to balance the series connections, each input is connected to a transistor in each of the three positions: close to

out, center, and close to power. This is only possible if there are three parallel series chains; therefore, introducing

balancing to a layout may incur significant overhead.

Dan Clein](https://image.slidesharecdn.com/nanometerlayouthandbookathighspeeddesign-170615123243/85/Nanometer-layout-handbook-at-high-speed-design-37-320.jpg)