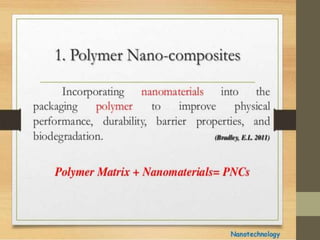

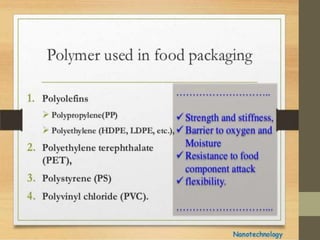

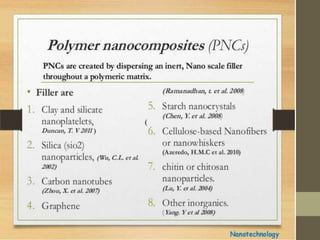

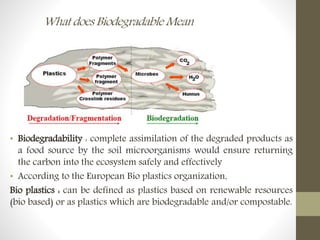

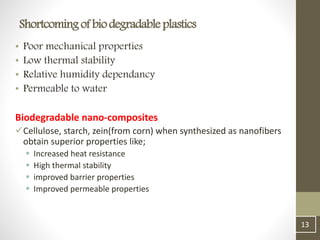

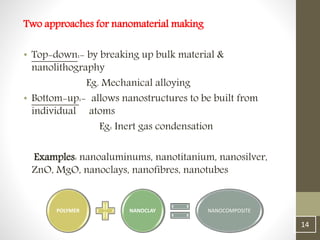

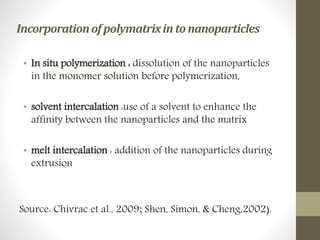

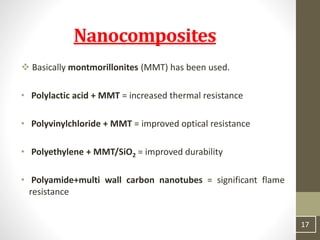

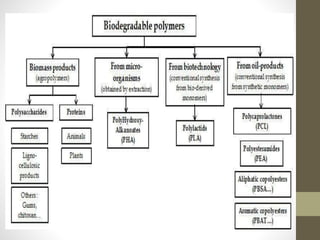

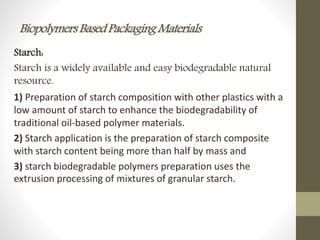

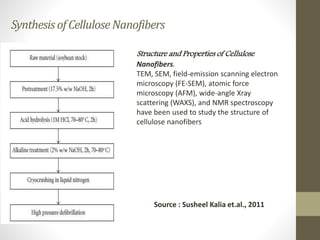

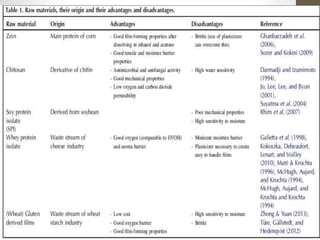

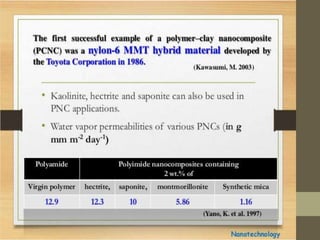

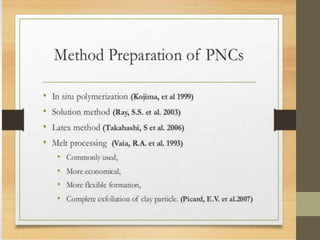

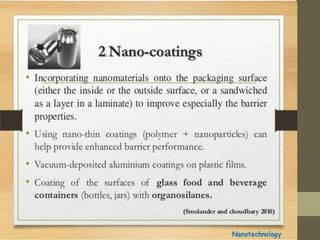

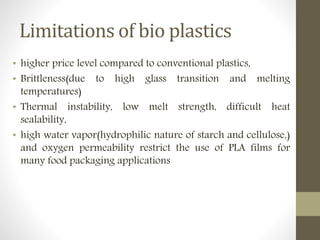

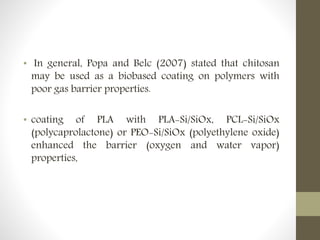

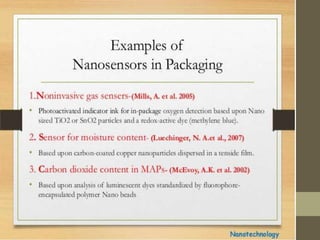

The document discusses biodegradable plastics, particularly those utilizing nanotechnology to enhance performance and sustainability. It outlines various biodegradable materials including starch, cellulose, and polyhydroxyalkanoates, while emphasizing the benefits of nanocomposites in improving mechanical, thermal, and barrier properties. Additionally, it highlights the challenges associated with biodegradable plastics, such as cost and performance limitations, and suggests approaches to overcome these issues through improved interactions between polymer matrices and nanofillers.