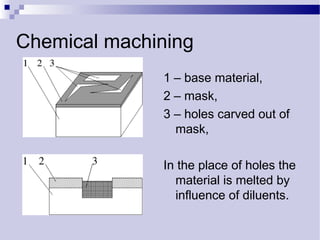

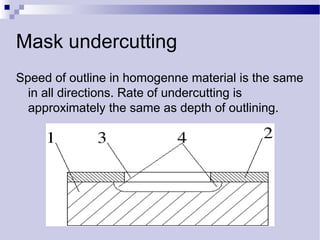

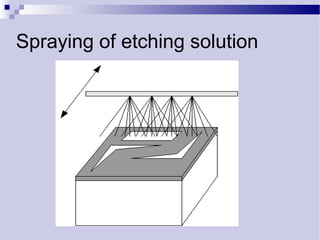

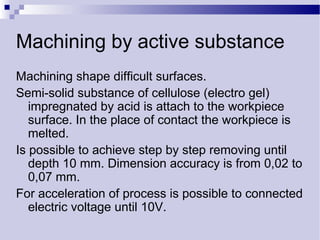

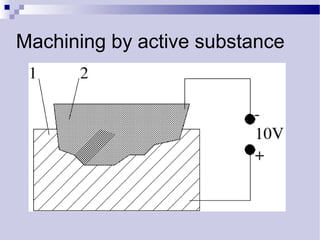

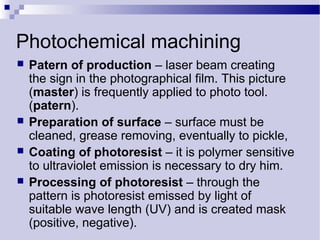

Chemical machining involves locally dissolving material using chemical etchants rather than mechanical tools. It can machine metals with complex shapes to high accuracy regardless of hardness. Common etchants include acids for ferrous metals and caustic soda for aluminum alloys. The workpiece is coated with a resistant mask and then etched where the mask exposes the material. Factors like etchant selection, masking, and agitation affect the etching rate and quality of surfaces produced. Chemical machining methods include clipping, milling, engraving, polishing, and those using active substances or photochemical processes to shape materials.