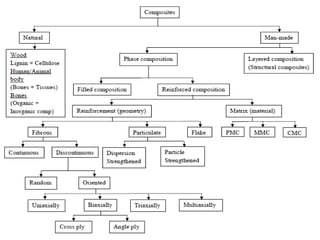

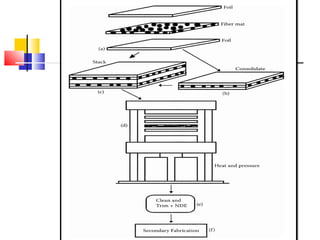

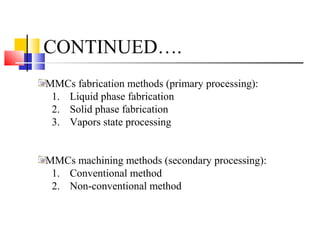

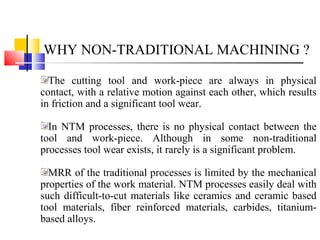

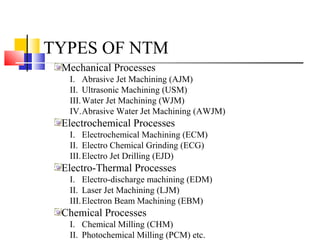

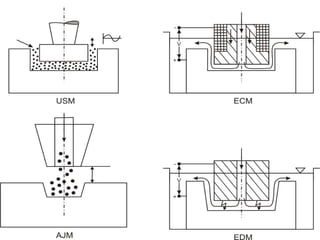

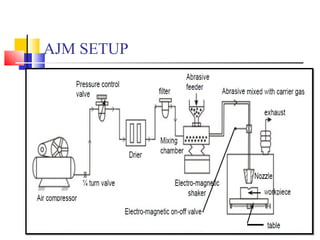

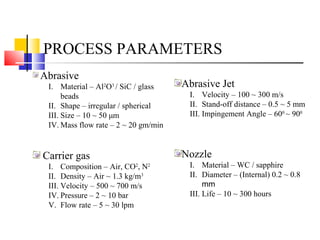

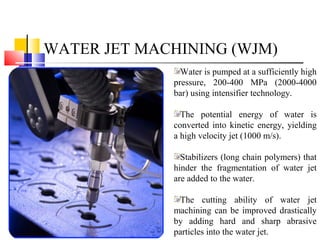

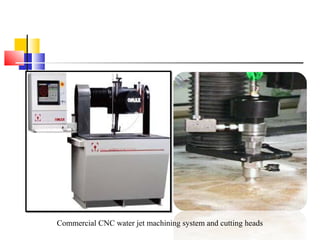

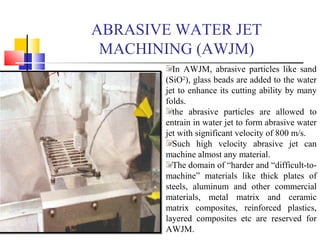

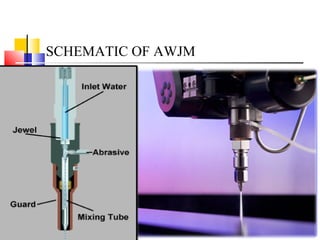

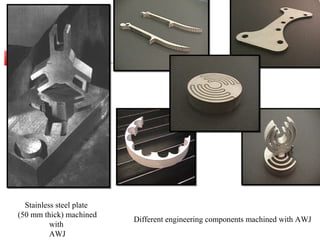

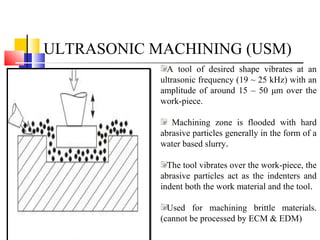

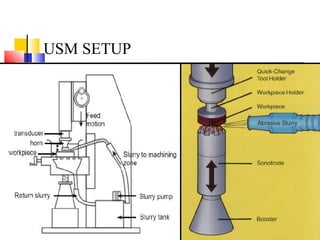

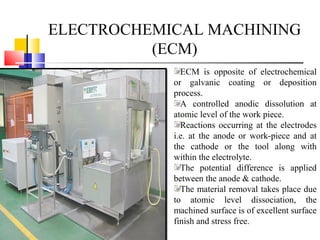

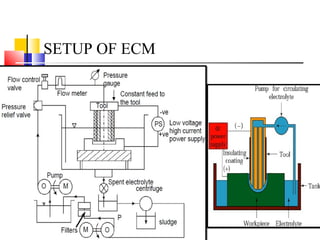

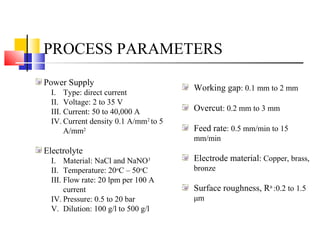

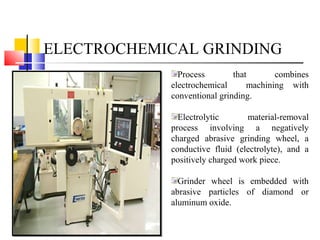

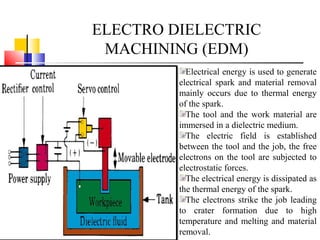

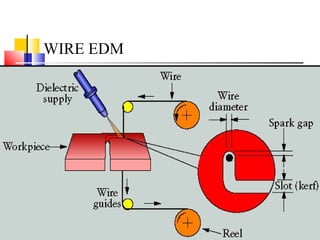

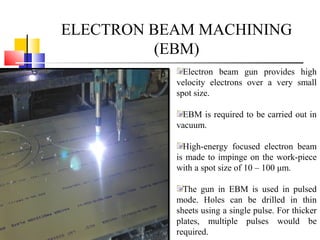

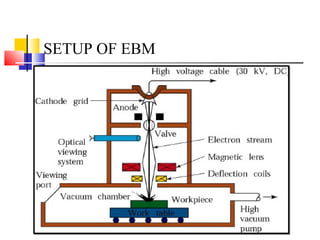

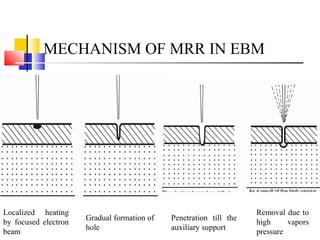

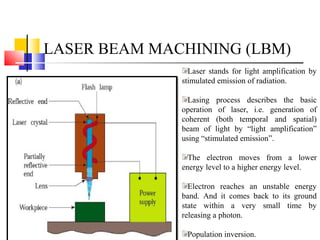

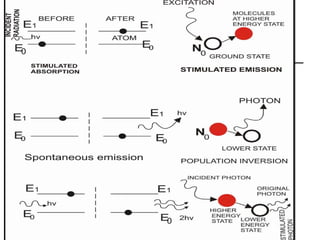

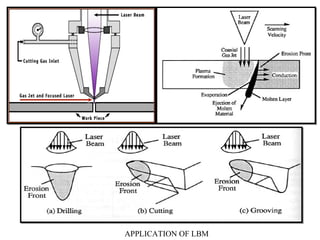

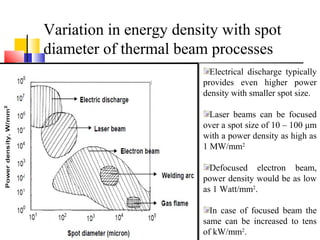

This document discusses non-traditional machining of metal matrix composites. It begins with background on composites and metal matrix composites. It then discusses primary and secondary processing of MMCs. Non-traditional machining is preferred over conventional machining for MMCs due to issues like tool wear and limitations in material removal rate with conventional processes. Various non-traditional machining processes are covered, including mechanical processes like abrasive jet machining and ultrasonic machining, electrochemical processes like electrochemical machining, electro-thermal processes like electrical discharge machining and laser beam machining, and chemical processes. Specific non-traditional machining techniques and their process parameters are described in detail.