1. The document outlines Sushant Labhasetwar's skills and experience as a process engineer, including 10 years of experience in chemical process design.

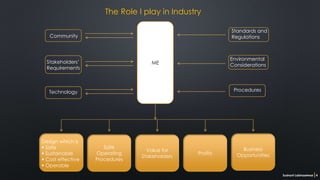

2. It describes the role he plays in industry, which includes ensuring designs are safe, sustainable, cost-effective, and operable while meeting standards, regulations, and stakeholder needs.

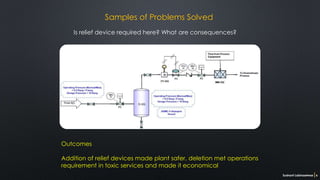

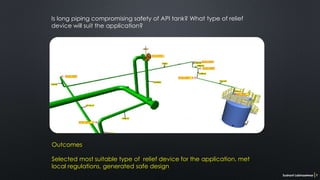

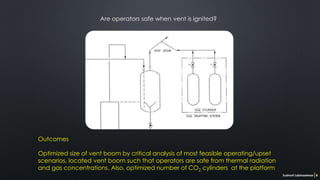

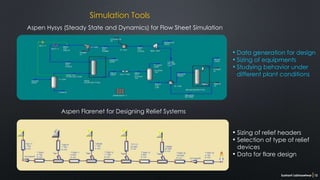

3. Examples of problems Sushant has solved are provided, such as optimizing relief valve selection and sizing to make a plant safer and more economical.