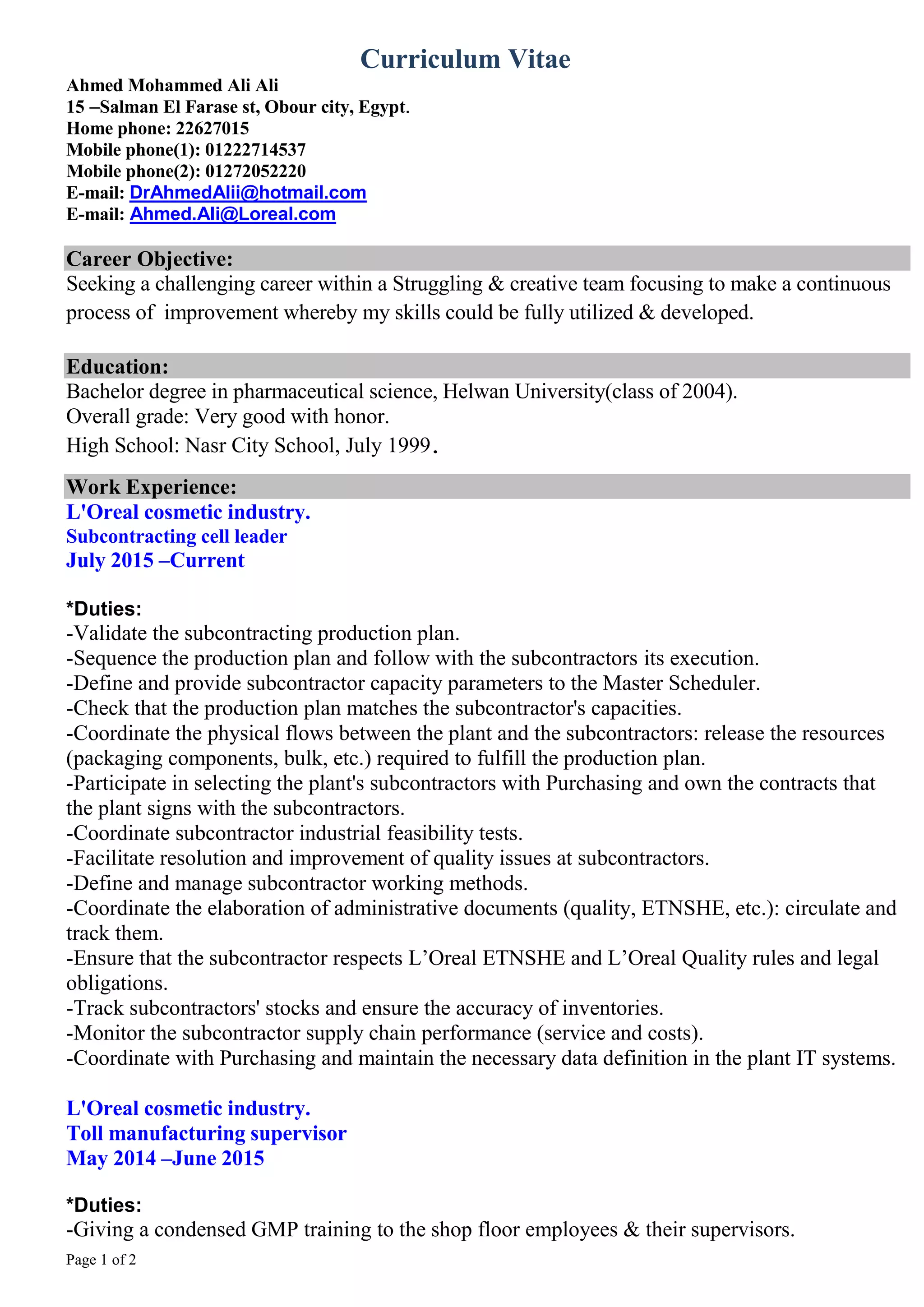

Ahmed Mohammed Ali Ali has over 15 years of experience in quality control and assurance roles in the pharmaceutical and cosmetics industries. He holds a Bachelor's degree in pharmaceutical science and has worked at L'Oreal, GlaxoSmithKline, and several other companies in Egypt. His experience includes managing quality control laboratories, supervising manufacturing operations, ensuring compliance with good manufacturing practices, and auditing quality systems. He is proficient in English and Microsoft Office applications.