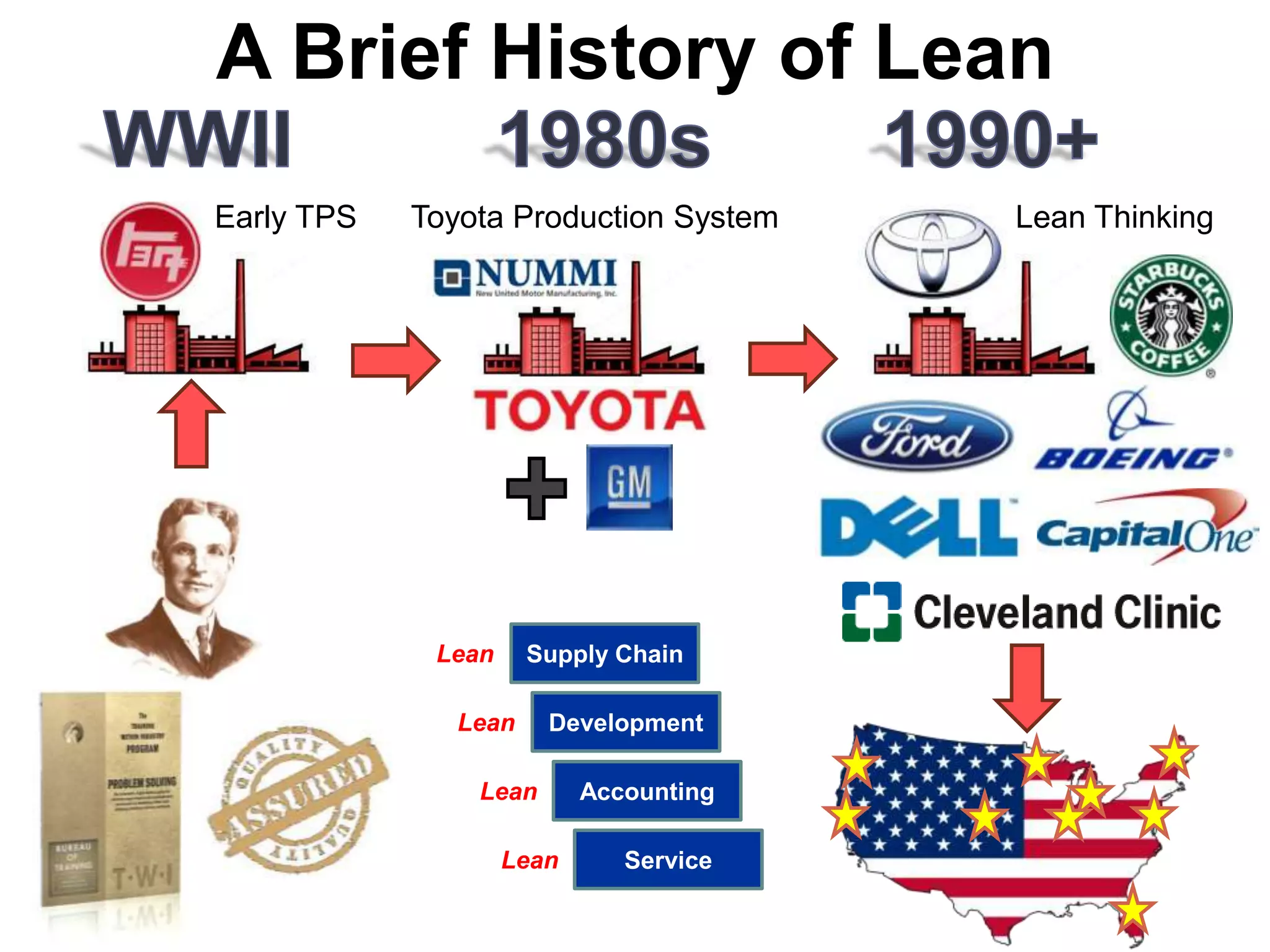

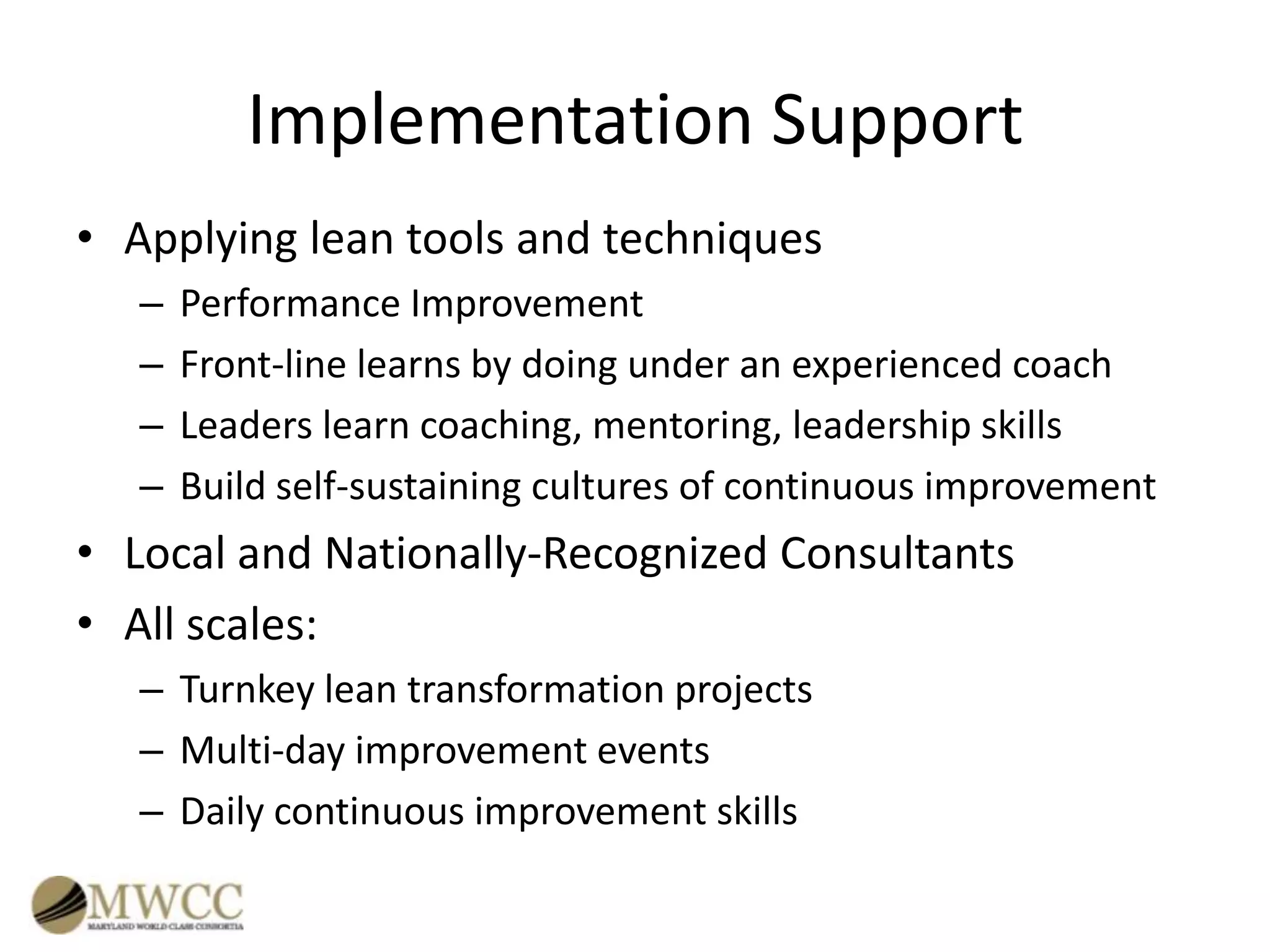

The Maryland World Class Consortia (MWCC) provides services to enhance competitiveness for Maryland organizations through lean thinking principles. It offers diagnostics, education, networking, and implementation support centered around lean thinking and the Toyota Production System. Services include over 20 workshops on lean topics, a lean facilitator certification program, member company tours and speakers, and implementation support through lean consultants. The goal is to help organizations apply tools like value stream mapping and develop a culture of continuous improvement.