Embed presentation

Downloaded 105 times

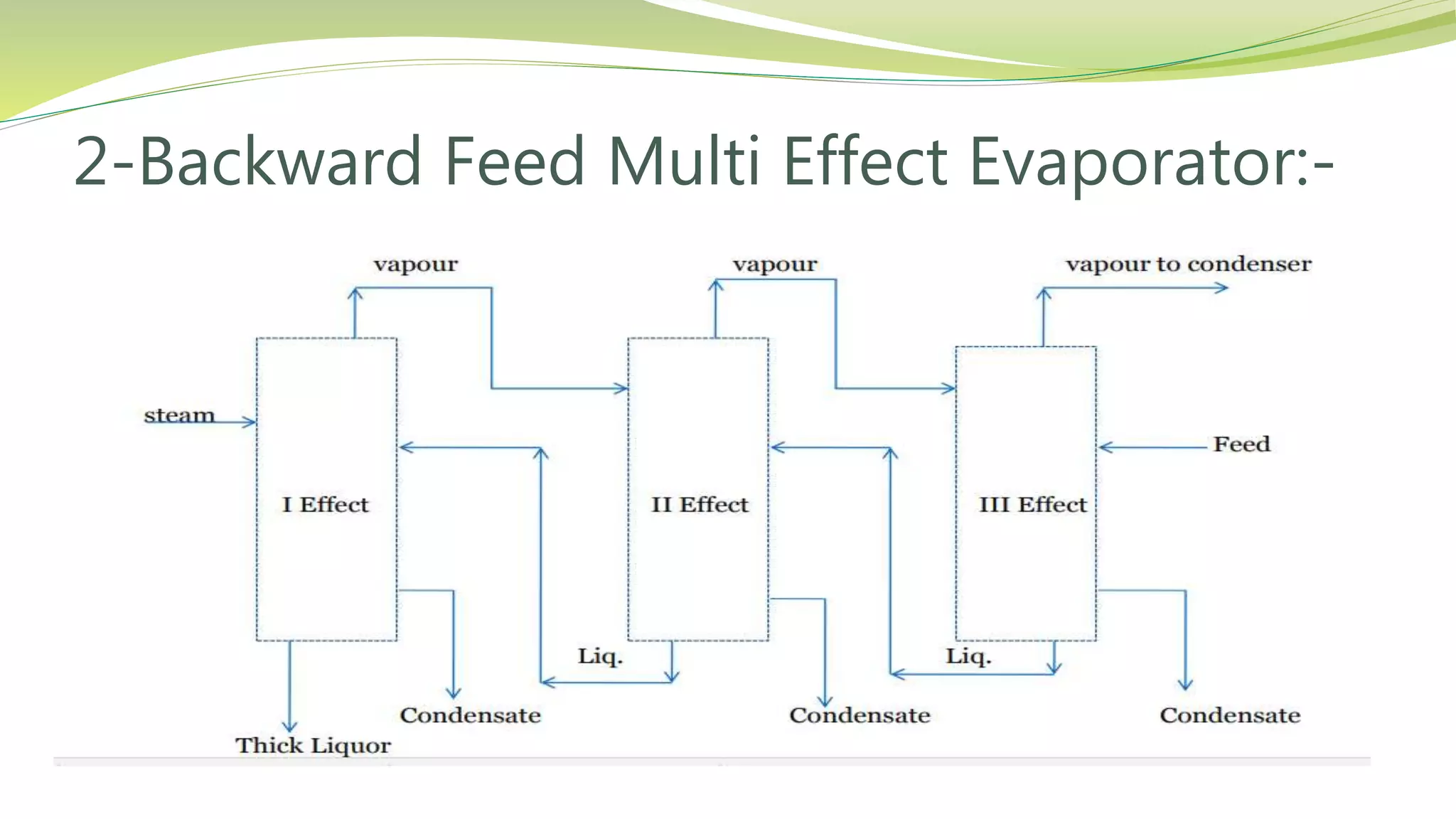

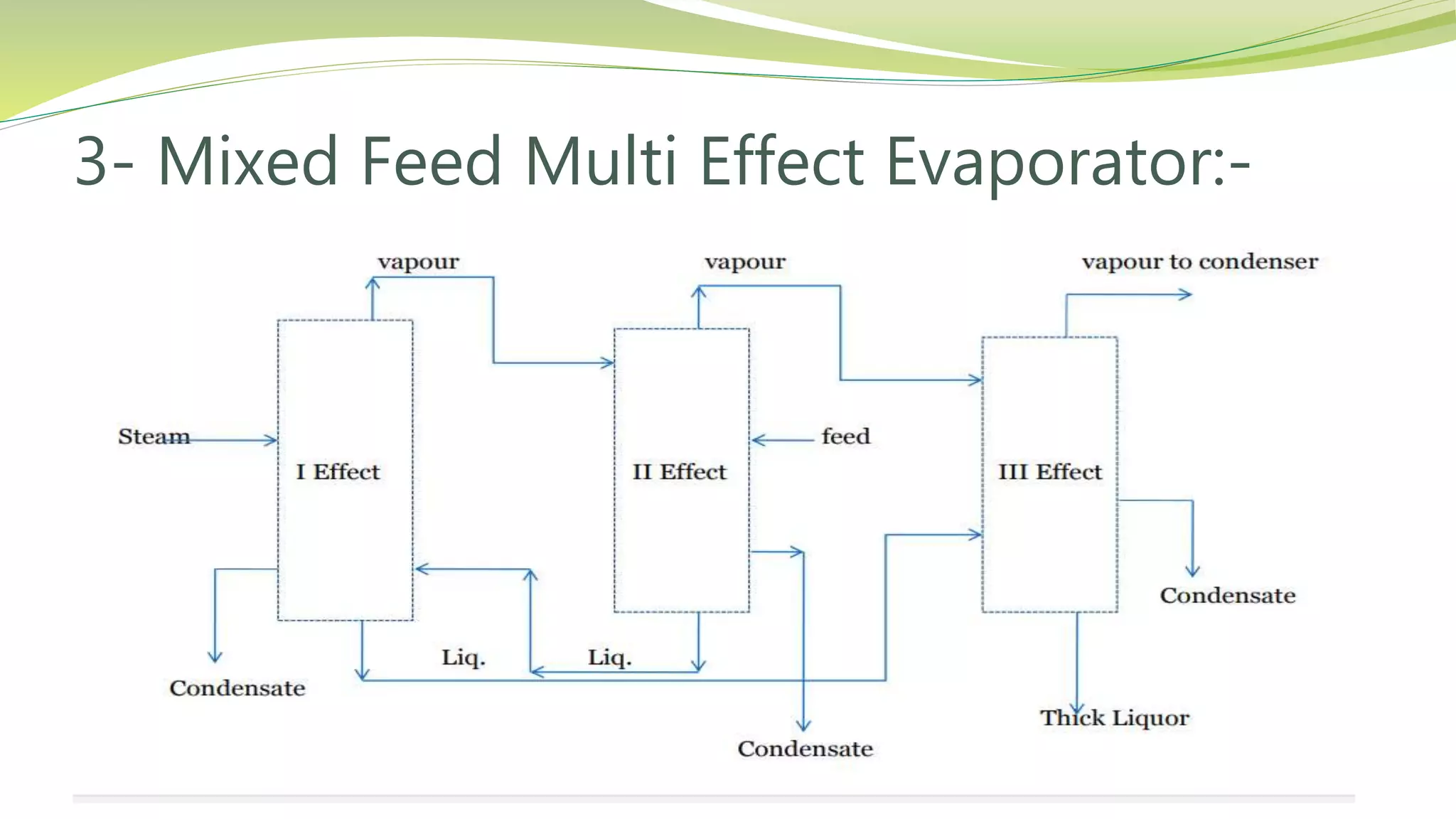

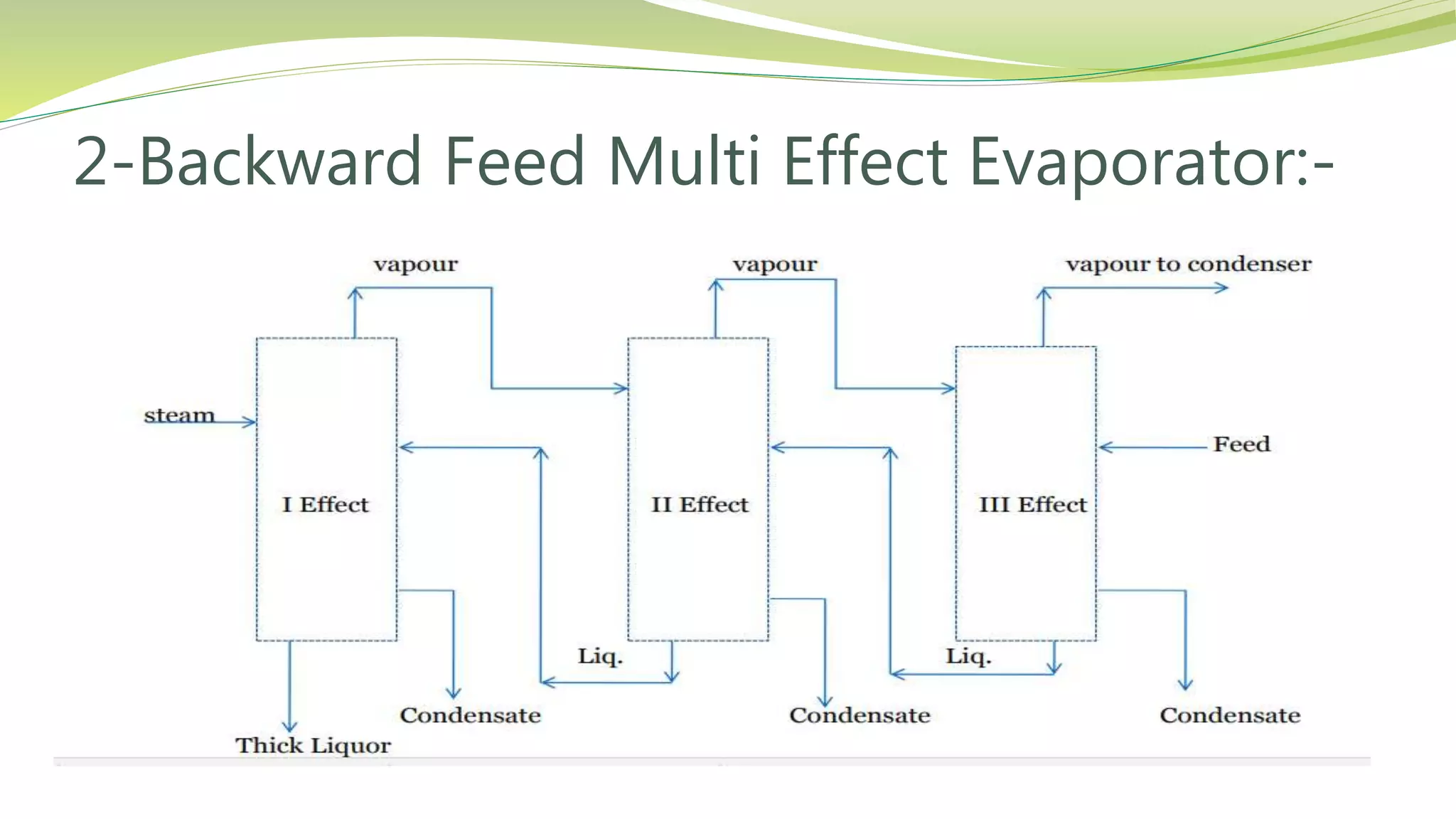

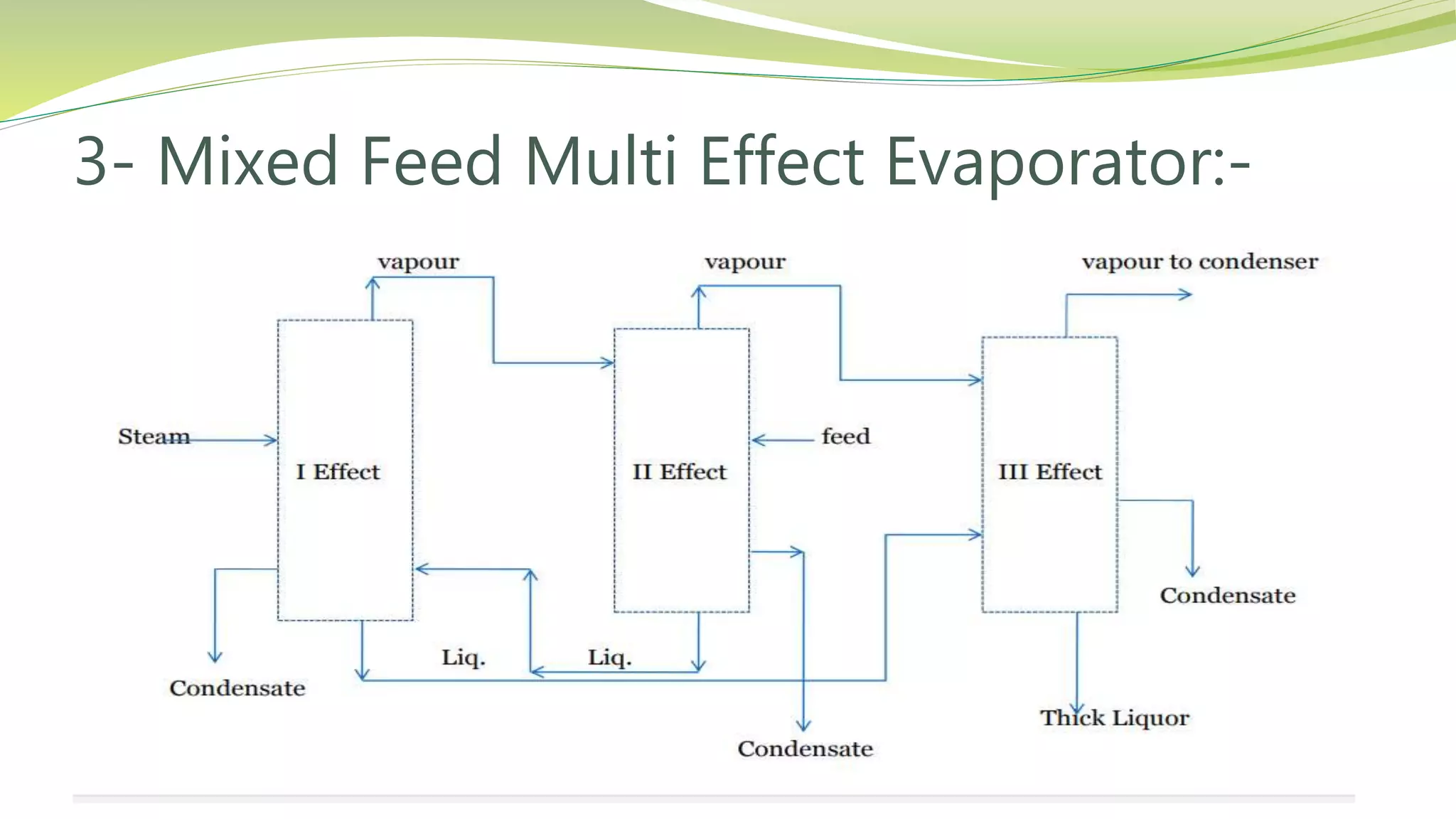

The document discusses multiple effect evaporators, which are used to efficiently concentrate solutions by removing solvent, mainly water, through evaporation. It explains that multiple effect evaporators use heat from steam to evaporate water in multiple stages, making the process more economical than single effect evaporators. Multiple effect evaporators are divided into three categories based on feed direction: forward feed, backward feed, and mixed feed. They have various applications like product concentration, solvent recovery, and crystallization. Key advantages include being an advanced system that is easy to operate and maintain cost effectively.