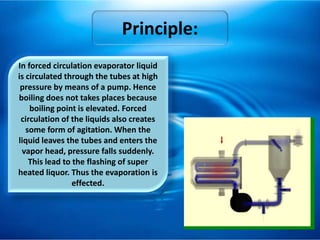

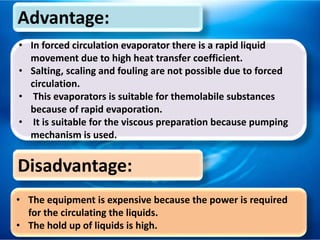

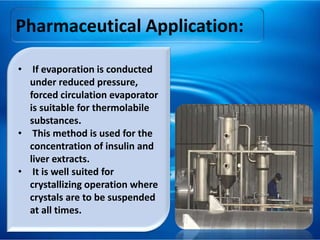

Forced circulation evaporators use pumps to circulate liquid through tubes at high pressure. This prevents boiling and elevates the boiling point. When the liquid exits the tubes, the sudden pressure drop causes flashing to vapor. This forced circulation and flashing leads to more efficient evaporation. Forced circulation evaporators are useful for evaporating viscous or heat-sensitive substances since the pumping action prevents localized overheating and the rapid flow reduces thermal damage. However, they require more energy due to the power needed to drive the pumps.