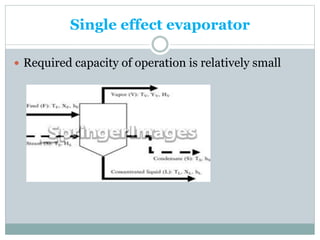

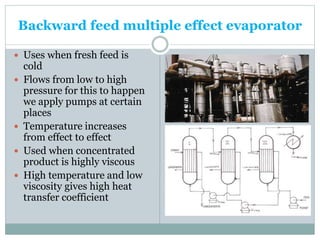

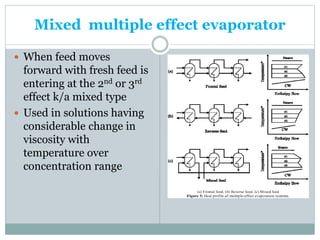

The document discusses various types of evaporators used to concentrate liquid solutions. It describes key properties that affect evaporation like concentration, solubility, temperature sensitivity, and foaming. The main types of evaporators covered are open kettle, horizontal natural circulation, vertical natural circulation, long tube vertical, falling film, forced circulation, agitated film, and open pan solar. Operation methods like single effect and multiple effect (forward feed, backward feed, parallel feed, mixed feed) are also summarized. Processing variables like temperature, pressure, and steam pressure that impact evaporator size and cost are outlined.