The document details the educational background and research interests of an author named Mohd Esa, who completed his M.E. in Power Electronics Systems and has published 12 research papers. It focuses on a study comparing two modulation techniques for three-phase inverters: Sinusoidal Pulse Width Modulation (SPWM) and Third Harmonic Pulse Width Modulation (THPWM), analyzing their effectiveness in reducing total harmonic distortion (THD). The results demonstrate that THPWM generally performs better than SPWM across various carrier frequencies.

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 04 Issue: 10 | Oct -2017 www.irjet.net p-ISSN: 2395-0072

© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 391

THD analysis of SPWM & THPWM Controlled Three phase Voltage

Source Inverter

Mohd Esa1 and Mohd Abdul Muqeem Nawaz2

1,2M.E. Student, EED, Muffakham Jah College of Engineering and Technology, Hyderabad, India

---------------------------------------------------------------------***---------------------------------------------------------------------

Abstract –The aim of this paper is to determine the Total

harmonic distortion (THD) of three phase voltage source

inverter (VSI) fed R-L load. The modulation Techniques usedis

Sinusoidal pulse width modulation (SPWM) and third

harmonic pulse width modulation (THPWM). The Carrier

frequency is varied to analyze its effect on Current THD and

Voltage THD.This paper also presents the comparison of

SPWM and THPWM controlled Inverter in terms of THD. The

simulation result shows THPWMhasbetter performancewhen

compared to SPWM. The simulation of circuit is done by using

MATLAB/Simulink.

Key Words: SPWM, THPWM, THD, Carrier Frequency.

1. INTRODUCTION

1.1 Stepped & PWM Inverters

Inverter converts input DC voltage into a.c. output voltage.

Three phase inverters are normally used for high power

applications [1].The applications of inverters include

uninterrupted power supply (UPS), a.c. motor speed

controllers etc. Voltage source inverter is capable of

supplying variable frequency variable voltage for speed

control of induction motors.VSI can be operated as stepped

wave inverter or a pulse width modulated (PWM) inverter.

For stepped wave inverter Output voltage can be varied by

varying input DC voltage. When input voltage is DC, variable

DC input voltage is obtained by connecting a chopper

between DC supply and inverter. When input voltage is a.c.,

variable DC input is obtained by connecting a controlled

rectifier between a.c. supply and inverter. The disadvantage

of stepped wave inverterislargeharmonicsoflowfrequency

in output voltage. Due to this low frequency harmonics, the

motor losses are increased at all speeds causing derating of

Motor. Harmonics content in induction motor current

increases at low speeds. The above drawbacks are

eliminated by using Pulse Width Modulated(PWM)inverter.

Harmonics and losses get reduced in PWM inverters.

For PWM inverter output voltage and frequency can be

controlled without external control. When input voltage is

DC, it is directly connected to PWM inverter. When the input

voltage is a.c., DC is obtained by connecting a diode bridge

rectifier and output of rectifier is connected to PWM

inverter.PWM basedinverterisconsideredinthis paper over

stepped wave inverter because of its harmonics reduction

ability.

1.2 Control Strategies

Various PWM control strategies have been developed in the

past two decades [2].To obtain variation of output voltage

and frequency PWM control strategies such as Sinusoidal

pulse width modulation (SPWM),Third harmonic pulse

width modulation (THPWM), Space vector pulse width

modulation(SVPWM) and 60° PWM are most commonly

used for three phase inverters. SPWM is simplest of all the

above PWM techniques. It was introduced by schonung and

stemmler in 1964[3]. The required signals for gates of

inverter are generated by comparing reference sine wave

and triangular carrier signal in SPWM technique. In 1975

Buja developed THPWM technique.THPWM is implemented

in same manner as SPWM the difference is thatreference a.c.

waveform is not sinusoidal but consists of bothfundamental

component and third harmonic component[1],[4]. The

advantages of PWM techniques are that they are easy to

implement and control, reduces lower order harmonics

[5].SPWM and THPWM techniques are analyzed and

compared in terms of harmonics in this paper.

1.3 Total harmonic distortion

Harmonic distortion is caused bynonlineardevicesinpower

system. A nonlinear device is one in which current is not

proportional to applied voltage.IEEE Standard 519-1992

recommends the requirements for harmonic control in

electrical power systems [6]. Thequalityof Outputvoltage of

inverter strongly related to total harmonic distortion

[7].THD is the measure of effective value of harmonic

components of a distorted waveform.

Where h is characteristic harmonic order, is harmonic

voltage and is fundamental voltage.](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-11-320.jpg)

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 04 Issue: 10 | Oct -2017 www.irjet.net p-ISSN: 2395-0072

© 2017, IRJET | Impact Factor value: 5.181 | ISO 9001:2008 Certified Journal | Page 398

Chart-4.6: Comparison of current THD’s for SPWM and

THPWM controlled VSI

5. CONCLUSIONS

A three phase VSI has been implemented with SPWM and

THPWM control strategies. Analysis of current THD and

voltage THD is done at carrier frequencies from 1000Hz to

3000Hz.Simulation results of SPWM controlled inverterand

THPWM controlled inverter are compared. From chart 4.5

and chart 4.6 it can be concluded that THPWM provides

better quality of output voltage and current whencompared

to SPWM controlled inverter i.e. both current THD and

voltage THD is lesser in case of THPWM.Although there is

variation in current THD and Voltage THD with variation in

Carrier frequency, it is clear that current THD is well below

5% as specified by IEEE standards in both SPWM & THPWM

inverters.

REFERENCES

[1] Muhammad H. Rashid, “Power Electronics-Circuits,

Devices and Applications” Pearson Education Incorporated,

2005.

[2] R.K. Pongiannan, and N. Yadaiah, “FPGA Based Three

Phase Sinusoidal PWM VVVF Controller,” IEEE ICEES

(International Conference on Electrical Energy Systems), pp.

34-39, 2011.

[3] J.Y. Lee, and Y.Y. Sun, “A New SPWM Inverter with

Minimum Filter Requirement, International Journal of

Electronics, Vol. 64, No. 5, pp. 815-826, 1988.

[4] Berrezzek Farid and Omeiri Amar, “A Study of New

Techniques of Controlled PWM Inverters” European Journal

of Scientific Research, Vol.32, No.1, 2009.

[5] Mahesh A. Patel, Ankit R. Patel, Dhaval R. Vyas and Ketul

M.Patel, “Use of PWM Techniques for Power Quality

Improvement” International Journal of Recent Trends in

Engineering, Vol. 1, No. 4, May 2009.

[6] "IEEE Recommended Practices and Requirements for

Harmonic Control in Electrical Power Systems," IEEE Std

519-1992.

[7] M. Baumann and J. W. Kolar, "Comparative evaluation of

modulation methods for a three-phase/switch buck power

factor corrector concerning the input capacitor voltage

ripple," in Power Electronics Specialists Conference, 2001.

PESC. 2001 IEEE 32nd Annual, 2001, pp. 1327-1332 vol. 3.

BIOGRAPHIES

Mohd Esa is currently pursuing M.E.

(Power Electronics systems) from

Muffakham Jah College of Engineering

and Technology,Hyderabad. HeReceived

his B.E degree from Osmania University,

Hyderabad. He is Member of

International Association of Engineers

(IAENG), Hong Kong. His research of interests includes

Multi level inverters and electric drives.

Mohd Abdul Muqeem Nawaz, was Born

in Hyderabad, India in 1994.He received

his B.E degree from Osmania University;

He is currently pursuing M.E (Power

Electronicssystems)fromMuffakhamJah

College of Engineering and Technology,

Hyderabad. He is Member of

International Association of Engineers (IAENG), Hong

Kong. His research interests include power electronics,

FACTS devices and power electronics applications to

power systems.](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-18-320.jpg)

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 04 Issue: 10 | Oct -2017 www.irjet.net p-ISSN: 2395-0072

© 2017, IRJET | Impact Factor value: 6.171 | ISO 9001:2008 Certified Journal | Page 1687

Harmonic Analysis of Three level Flying Capacitor Inverter

Mohd Esa1, Mohd Abdul Muqeem Nawaz2 & Syeda Naheed3

1,2,3M.E. Student, EED, Muffakham Jah College of Engineering and Technology, Hyderabad, India

---------------------------------------------------------------------***---------------------------------------------------------------------

Abstract –The aim of this paper is to determine the Total

harmonic distortion (THD) of three phase three level flying

capacitor inverter fed star connected R-L load. The

modulation Techniques used is Phase Disposition Sinusoidal

pulse width modulation (PD-SPWM) and Phase Opposition

Disposition Sinusoidal pulse width modulation (POD-

SPWM).The Modulation index is varied to analyze its effect on

Current THD and Voltage THD.This paper also presents the

comparison of PD-SPWM and POD-SPWM controlled Flying

capacitor Inverter in terms of THD. The simulation result

shows that PD-SPWM has betterperformance whencompared

to POD-SPWM. The simulation of circuit is done by using

MATLAB/Simulink.

Key Words: PD-SPWM, POD-PWM,THD,ModulationIndex.

1. INTRODUCTION

1.1 Multilevel Inverters

Multilevel inverters have drawn tremendous interest in

power industry owing to their advantages such as higher

efficiency, lower common modevoltage,lowervoltagestress

on power switches, lower dv/dt ratio, no EMI problems & its

suitability for high voltage and high current applications

[1].There are three types of multilevel inverters. They are

Diode clamped or Neutral clamped, Flying capacitor or

Capacitor clamped &. Cascaded Hbridgemultilevel inverters

[2]-[3].During the 1980s the development of the Multilevel

Converters did not move much forward. Onlyafterten years,

at the turn of the decade, finally appeared articlesabout new

applications, e.g. nuclear fusion, and new control methods.

The next turning point came at the beginning of the 1990s

when Meynard and Foch (1992) presented the flying

capacitor converter as a multilevel chopper and a multilevel

inverter.

Fig-1.1.1: Classification of Multilevel Inverter

The FCMLI is considered For THD analysis in this paper

because it is easier to increase number of levels in this

inverter than the diode clamped multilevel inverters. The

advantage of FCMLI is that it can control both real and

reactive power flow.

1.2 Multilevel Inverter PWM Strategies

PWM control strategies are development to reducetheTotal

Harmonic Distortion [4].PWM strategies used in

conventional inverters can be modified to use in MLI.The

advent of multilevel inverter PWM modulation

methodologies can be classified according to switching

frequency as shown in figure 1.2.1

Fig-1.2.1: Classification of Multilevel Inverter PWM

Strategies

There are several Multi carrier based High frequency

techniques such as i) Phase disposition PWM (PDPWM) ii)

Phase Opposition DispositionPWM (PODPWM)iii)Alternate

Phase Opposition Disposition PWM (APODPWM) iv) Phase

Shift PWM (PSPWM) v) Alternate Phase Shift PWM

(APSPWM) vi) CarrierOverLapPWM(COPWM)vii)Variable

Frequency PWM (VFPWM) viii) Alternate Variable

Frequency PWM (AVFPWM).In multilevel Inverters

modulation index is defined as follows

In this Paper, PD and POD SPWM strategies are considered

for triggering switches of three level flying capacitor

inverter.](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-19-320.jpg)

![International Research Journal of Engineering and Technology (IRJET) e-ISSN: 2395-0056

Volume: 04 Issue: 10 | Oct -2017 www.irjet.net p-ISSN: 2395-0072

© 2017, IRJET | Impact Factor value: 6.171 | ISO 9001:2008 Certified Journal | Page 1693

From the chart 5.1 and 5.2 it is observed that as the

modulation index increases both current THD and Voltage

THD decreases. The comparison of voltage THD for PD-

SPWM and POD-SPWM controlled 3 phase 3 level flying

capacitor inverter is shown in chart 5.3 & the comparison of

current THD for PD-SPWM and POD-SPWM controlled 3

phase 3 level flying capacitor inverter is shown in chart 5.4

Chart-5.3: Comparison of voltage THD’s for PD-SPWM &

POD-SPWM controlled 3 level Flying capacitor inverter

Chart-5.4: Comparison of current THD’s for PD-SPWM &

POD-SPWM controlled 3 level Flying capacitor inverter

6. CONCLUSION

A three phase three level flying capacitor inverter has been

implemented with PD-SPWM and POD-SPWM control

strategies. Analysis of current THD and voltage THD is done

at Modulation index from 0.6 to 1(Unity). Simulation results

of PD-SPWM controlled flying capacitor inverter and POD

SPWM controlled flying capacitor inverter are compared.

From chart 5.3 and chart 5.4 it can be concluded that PD-

SPWM provides better quality of output voltage and current

when compared to POD-SPWM controlled inverter i.e. both

current THD and voltage THD is lesser in case of PD-SPWM.

REFERENCES

[1] Muhammad H. Rashid-“Power Electronics-Circuits,

Devices and Applications” Pearson Education Incorporated,

2005.

[2] Tolbert. L. M and Pend. F. Z -“Multilevel Converter as a

Utility Interface forRenewableEnergySystems”,IEEEPower

Engineering Society Meeting, Vol. 2, pp. 1271- 1274, 2000.

[3]BK Bose-“Power electronics-An emerging technology”

IEEE Transactions on Industrial Electronics, vol.36,no.3, pp.

403–12, Aug 1989.

[4] Mohd Esa and Mohd Abdul Muqeem Nawaz, "THD

analysis of SPWM & THPWM ControlledThreephaseVoltage

Source Inverter", International Research Journal of

Engineering and Technology (IRJET), vol.04,no.10,pp.391-

398, 2017.

BIOGRAPHIES

Mohd Esa is currently pursuing M.E.

(Power Electronics systems) from

Muffakham Jah CollegeofEngineeringand

Technology, Hyderabad. He Received his

B.E degree from Osmania University,

Hyderabad. He is Member of International

Association of Engineers (IAENG), Hong

Kong. His research of interests includes Multi level

inverters and electric drives.

Mohd Abdul Muqeem Nawaz, was Born in

Hyderabad, India in 1994.He received his

B.E degree from Osmania University;Heis

currently pursuing M.E (Power

Electronics systems) from Muffakham Jah

College of Engineering and Technology,

Hyderabad. He is Member of International

Association of Engineers (IAENG), HongKong. Hisresearch

interests include power electronics, FACTS devices and

power electronics applications to power systems.](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-25-320.jpg)

![Common Mode Voltage reduction in Diode Clamped

MLI using Phase Disposition SPWM Technique

Mr.Mohd Esa

M.E. Student, Department of Electrical Engg.

M.J.C.E.T., Hyderabad, India

zmohdesa@gmail.com

Mr.J.E.Muralidhar

Associate Professor, Department of Electrical Engg.

M.J.C.E.T., Hyderabad, India

muralidhareed@mjcollege.ac.in

Abstract—The aim of this paper is to reduce the Common

Mode Voltage (CMV) in the Diode Clamped Multilevel Inverter

(DCMLI).Three phase star connected RL load is connected to

DCMLI. The common mode voltage exists between star point of

load & system ground. Premature failure of bearings of

Induction Motor (IM) is caused by CMV and is necessary to

reduce. In this paper, Phase Disposition Sinusoidal Pulse Width

Modulation (PD SPWM) technique is used for reduction of CMV

and LC filter is used for reduction of Harmonics.MATLAB

Simulink is used for the simulation of circuit. Total Harmonic

Distortion (THD) and CMV are investigated.

Keywords—CMV,THD,PD SPWM,DCMLI

I. INTRODUCTION

In high power & high voltage applications, Multilevel

Inverters (MLI) have attracted more attention due to their

advantages such as lesser CMV, lesser voltage stress on

switches and low dv/dt ratio [1].The conventional pulse width

modulated voltage source inverter has the problem of presence

of more harmonics when compared to multilevel inverters.

They main drawback of CMV is that it give rise to shaft

voltage & bearing currents [2], [3].CMV and THD must be

reduced for better operation of IM drives. Some methods for

reduction of CMV are application of common mode choke,

dual bridge inverters [4], four leg inverters [5], & improved

modulation strategies [6].CMV can be reduced in MLI by

applying proper control strategy. Switching states in MLI is

more in number so the output voltage is stepped in smaller

increments. This mitigates harmonics at low switching

frequencies thus decreasing the losses in switches. Leakage

current gets decreased as dv/dt is low in MLI.CMV gets

reduced in MLI, which avoids failure of bearing [7].

The concept of multilevel began with the 3- level converter

which is often known as neutral point converter. Here

converter refers to the power flow in both the directions i.e.

from D.C. to a.c. called as inverter and from a.c. to D.C. called

as rectifier. The commercially existing MLI types are Diode

Clamped (DC-MLI) or Neutral-Point Clamped (NPC-MLI)

[8], Flying Capacitor (FC-MLI) or Capacitor Clamped &

Cascaded H-bridge multilevel inverter (CHB-MLI). Though

CHB-MLI was invented in 1975 it found its application in

1990, hence DC-MLI was considered as first generation of

multilevel inverters. DC-MLI was the first one that made it

possible to produce an output voltage from only one D.C.

source. All devices in DC-MLI are switched at the

fundamental frequency thus its efficiency is high & when

number of levels of DC-MLI increases, harmonic content in

output voltage gets low enough to avoid need of filters but

disadvantage of DC-MLI is requirement of excessive

clamping diodes when numbers of levels are high.

The Flying Capacitor Multilevel Inverter is an alternative

to DC-MLI.Flying capacitor MLI uses capacitors for

clamping.FC-MLI is used in various high power applications

because it is easy to increase number of levels in FC-MLI than

the DC-MLI.For m-level, flying capacitor inverter consists of

2× (m-1) switches, (m-1) main capacitors and (m-1) × (m-2)/2

auxiliary capacitors in each leg [9].FC-MLI can control both

active & reactive power flow but for active power

transmission, switching frequency & switching losses are

more.

Cascaded H-bridge MLI is also recognized as Multicell

inverter. In CHB-MLI topology output voltage is the sum of

all of the individual H-bridge outputs because a.c. output of

each H-bridge is connected in series [10]. For m-level inverter

number of cells required is (m-1)/2.The components used are

less, because clamping diodes or clamping capacitors are not

required in this topology. The drawback of CHB-MLI is that

each H-bridge requires separate D.C. sources.

Inverter’s output voltage can be controlled by various

modulation techniques. The classifications of these techniques

are based on fundamental switching frequency and high

switching frequency. Modulation techniques based on

fundamental switching frequencies are Space Vector Control

& Selective Harmonic Elimination [11]. High switching based

methods are Sinusoidal Pulse Width Modulation (SPWM),

Selective Harmonic Elimination (SHE-PWM), Space Vector

Modulation (SVM).These PWM techniques are easy to

implement and control, and they reduce lower order

harmonics.SPWM is simplest of all the above techniques. In

1964, SPWM was introduced by schonung and

stemmler.SPWM technique does not require any computations

and is very popular in industrial applications.Multi carrier

techniques based on classical SPWM has been developed.

279978-1-5386-3695-4$31.00 c 2018 IEEE](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-27-320.jpg)

![Phase shifting and level shifting are major techniques of

Multicarrier SPWM. The Multi carrier based High frequency

techniques are

Phase Shift PWM (PSPWM)

Alternate Phase Shift PWM (APSPWM)

Phase Disposition PWM (PDPWM)

Phase Opposition Disposition PWM (PODPWM)

Alternate Phase Opposition Disposition PWM

(APODPWM)

Carrier Over Lap PWM (COPWM)

Variable Frequency PWM (VFPWM)

Alternate Variable Frequency PWM (AVFPWM).

These techniques are helpful to reduce THD and CMV

in multilevel inverters [6]. In this paper, CMV and THD

reduction in DCMLI using PDSPWM is presented.

II. COMMON MODE VOLTAGE

A. Definition:

Voltage that exists between neutral-point of wye

connected load & system ground is known as common mode

voltage (or) voltage between star point of load and input D.C.

midpoint (or) The CMV is defined as the voltage potential

difference between the mid-point of the D.C. link capacitors

and the star point of the load network. Mathematical

expression for CMV is shown in equation (1).

(1)

Where , , are the phase voltages. is common

mode voltage. A generalized drive system is represented in

fig. 1.

Fig.1. A generalized drive system

It has been observed that each switching state has its own

related CMV level.CMV has different values of ± 6 or

± for conventional three phase two level inverter based

on the inverter’s switching state selected.

B. Effects of common mode voltage:

a) Regardless of number of legs & levels, high

amplitude & high frequency CMV exists always in

pulse width modulated inverters because of its

switching operation which results in common mode

current (CMC) through parasitic capacitors between

inverter, loads & ground respectively. This CMC

cause’s mal operation of inverter control system as it

is a source of EMI noise.

b) Shaft voltages on the rotor are caused by pulse width

modulated inverters because of CMV.Premature

failure of IM bearings is caused when this shaft

voltage exceeds the voltage limit of bearings

lubricant.CMV is required to reduce by choosing

specific reduction technique.

C. Reduction methods for common mode voltage:

Few methods to combat CMV are represented in fig.2.

Fig. 2.CMV reduction techniques

Extra leg is used in four leg inverter which is connected to star

point of load to reduce CMV but in four leg inverter switching

scheme becomes complex. In reducing electromagnetic

interference, eliminating CMV and bearing currents of motor

the Dual Bridge Inverter (DBI) topology is more effective. In

DBI topology, two parallel inverters with reverse polarities is

connected to double winding motor to eliminate CMV.Size

and cost are disadvantage for this CMV reduction technique.

In this paper, Multicarrier based Phase Disposition SPWM

technique is used to reduce CMV.

280 4th International Conference on Electrical Energy Systems (ICEES)](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-28-320.jpg)

![III. TOTAL HARMONIC DISTORTION

THD is the measure of effective value of harmonic

components of a distorted waveform. Presence of nonlinear

devices in power system is cause of harmonic distortion.IEEE

Standard 519-1992 recommends the requirements for

harmonic control in electrical power systems. Inverter’s output

voltage quality strongly related to total harmonic distortion. A

mathematical expression for THD is shown in equation (2).

(2)

Where h is harmonic order, is harmonic voltage, and is

fundamental voltage. To do the THD analysis of output

voltage of inverter Fast Fourier transform (FFT) is used. The

algorithm requires a large amount of calculations but with

MATLAB simulation software, calculations are done easily.

In this paper THD is also reduced along with CMV in PD

SPWM controlled DCMLI.

IV. DIODE CLAMPED MULTILEVEL INVERTER

In 1981,DCMLI was proposed by Nabae et al., DC-MLI is

also known as Neutral-Point Clamped Inverter (NPC-MLI)

[8].The m-level inverter leg contains (m-1) D.C. bus

capacitors, 2×(m-1) switches & required clamping diodes are

(m-1) × (m-2).

A. 3-level Diode clamped Inverter

Power circuit of single leg of 3- level DCMLI is shown in

fig. 3. In each leg it requires 4 switches. Total of twelve

switches are required in three phase 3 level DCMLI. SW1,

SW2 are IGBTs in upper half of the first leg and SW3, SW4

are IGBTs in lower half of the first leg and it has two

clamping diodes in each leg. Main capacitors required are two.

The operation of 3-level DCMLI is as follows. When switch

SW1, SW2 are ON and SW3, SW4 are OFF output phase

voltage is /2.When SW2, SW3 are ON and SW1, SW4 are

OFF output phase voltage is zero. When SW3 and SW4 are

ON and SW1, SW2 are OFF output phase voltage is /2.

Table 1 shows the triggering states and output phase voltage

magnitude for phase A of 3- level diode clamped inverter.

Requirement of the clamping diodes increases as inverter’s

output voltage level increases which makes this topology

bulky.

TABLE 1: TRIGGERING STATES AND MAGNITUTE OF OUTPUT PHASE

VOLTAGE FOR 3-LEVEL DIODE CLAMPED INVERTER (PHASE A)

Triggering States Phase

VoltageSW1 SW2 SW3 SW4

OFF OFF ON ON -Vdc/2

OFF ON ON OFF 0

ON ON OFF OFF +Vdc/2

Fig. 3. Single leg of 3- level DCMLI.

B. 5-level Diode clamped Inverter

Power circuit of single leg of 5-level DCMLI is shown

in Fig.4.It needs eight switches in each leg. There are total 24

switches in three phase five level DCMLI.SW1, SW2, SW3 &

SW4 are IGBTs in upper half of the first leg and SW5, SW6,

SW7 & SW8 are the IGBTs in lower half of the first leg, five

level diode clamped inverter has 12 clamping diodes in each

leg. Main capacitors required are four. Thus for three phase

five level DCMLI has 36 clamping diodes. Table 2 shows

triggering states to synthesize five level phase output voltage.

The steps to produce the 5- level phase voltages are as

follows.

Switch ON,IGBTs from SW1 to SW4 for an output

phase voltage

Switch ON, IGBTs from SW2 to SW5 for an output

phase voltage

Switch ON, IGBTs from SW3 to SW6 for an output

phase voltage

Switch ON, IGBTs from SW4 to SW7 for an output

phase voltage

Switch ON, IGBTs from SW5 to SW8 for an output

phase voltage

4th International Conference on Electrical Energy Systems (ICEES) 281](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-29-320.jpg)

![Fig. 11(iv).9-Level DCMLI CMV waveform

Fig. 11(v).Line voltage THD analysis of 9-level DCMLI without filter

Fig. 11(vi).Line voltage THD analysis of 9-level DCMLI with LC filter

Table 3 shows the CMV and %THD for two level VSI, 3, 5, 7

and 9 level Diode clamped Inverter using Phase Disposition

SPWM technique with and without LC filter.

TABLE 3: CMV AND %THD VALUES FOR PD SPWM CONTROLLED

DCMLI

2-level

VSI

3-Phase PD SPWM Controlled DCMLI

3-level 5-level 7-level 9-level

CMV

(V)

145.2 81.68 40.33 25.66 17.06

THD

(%)

Without

filter

97.63 42.23 21.60 13.76 10.97

With

filter

28.02 11.97 6.31 4.28 3.52

Variation of CMV and % THD with level of Inverter is shown

in fig. 12.

Fig.12.Variation of CMV and THD with level of Inverter

From the fig. 12 it can be witnessed that as CMV and %THD

reduces with increase in inverter’s level, nature of output

voltage gets improved which reduces total harmonic distortion

by decreasing lower order harmonics. Table 3 clearly shows

that as the level of inverter increases, number of steps in

output voltage increases which reduces CMV.

VII. CONCLUSION

Diode clamped multilevel inverter for three, five, seven and

nine level using PD SPWM is simulated in Matlab/Simulink

software.Table-3 evidently shows that two level inverter

produces high %THD & CMV which causes high leakage

current & premature failure of IM bearing. From simulation

results it can be concluded that CMV can be reduced in

DCMLI by employing PD-SPWM strategy. DCMLI reduces

CMV by reducing dv/dt in output voltage and thus flow of

leakage current in motor gets reduced [12].

288 4th International Conference on Electrical Energy Systems (ICEES)](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-36-320.jpg)

![APPENDIX

MATLAB/Simulink Parameters:

1. Input Voltage =440V

2. Load R=100 Ohms, L=50e-3 Henry

3. System frequency=50Hz

4. Switching frequency

5. Amplitude Modulation Index 0.8

6. Frequency Modulation Index

7. LC filter: L=5.7e-3 Henry, C=3.45e-6 Farad

REFERENCES

[1] M.H. Rashid,“Power Electronics Circuits, Devices & Applications”

Pearson Education Incorporated, 2005.

[2] Jay M.Erdman,R.J.Kerkman,D.W.Schlegel & G.L.Skibinski , “Effect

of PWM Inverters on A.C. Motor Bearing currents and Shaft voltages,”

I.E.E.E. Trans. on Ind. App., Vol.32, No. 2 , pp.250-

259,MAR/APR,1996.

[3] Doyle Busse,Jay Eradman,R.J.Kerkman,Dave Schlegel & Gary

Skibinski , “System Electrical Parameters and their effects on Bearing

currents,” I.E.E.E. Trans. on Ind. App. ,Vol.33, No.2, pp. 577-583,

MAR/APR ,1997.

[4] R.S. Kanchan, P.N. Tekwani, M.R. Baiju, K. Gopakumar and A. Pittet,

“3-level Inverter configuration with Common Mode Voltage elimination

for Induction Motor Drive,” I.E.E. Proceedings- Elec. Power App., Vol.

152, No. 2, pp.261-270, MAR 2005.

[5] Alexander L. Julian, Giovanna Oriti, and Thomas A. Lipo, “Elimination

of Common Mode Voltage in 3-Phase Sinusoidal Power Converters,”

I.E.E.E. Transactions on Power Electronics Vol.14,No.5 , pp.982-989

,SEPT 1999.

[6] M.M.Renge and H.M.Suryawanshi , “ Multilevel Inverter to Reduce

Common Mode Voltage in A.C. Motor Drives Using SPWM

Technique.” pp.21-27,Journal of Power Electronics, Vol. 11, No. 1, JAN

2011.

[7] M.M.Renge and H.M.Suryawanshi , “5-Level Diode Clamped Inverter

to Eliminate Common Mode Voltage & Reduce dv/dt in Medium

Voltage Rating Induction Motor Drives.”, I.E.E.E. Trans. on Power

Electronics ,Vol.23 , No. 4 , pp.1598-1607,JUL,2008.

[8] A.Nabae, I. Takahashi, H.Akagi‘A new Neutral Point CIamped PWM

Inverter’’ I.E.E.E. Trans. on Ind. App., Vol. IA-I7, No.5,pp.518-52

SEPT/OCT,1981.

[9] T. A Meynard, H. Foch, “Multilevel conversion: High voltage Choppers

& voltage source inverters”,I.E.E.E.-Power Electronics Specialists Conf.

Rec., pp.397-403,1992.

[10] P. W. Hammond, “A new approach to enhance power quality for

medium voltage A.C. drives”,I.E.E.E. Trans. on Ind. App., vol. 33, no. I,

pp. 202-208, JAN./FEB 1997.

[11] M.H.Rashid,“Power Electronics Hand book ” , Edition,Butterworth-

heinemann,pp.399-400

[12] Atanda k Raji and Mohamed T E Kahn, “Investigation of common

mode voltage and ground leakage current of grid connected transformer

less PV inverter topology” Journal of Energy in Southern Africa ,Vol 26

No 1 February 2015.

4th International Conference on Electrical Energy Systems (ICEES) 289](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-37-320.jpg)

![Mr.Mohd Esa

M.E. Student, Electrical Engg. Dept.

Muffakham Jah College of Engg. & Tech.

Hyderabad, India

zmohdesa@gmail.com

Mr.J.E.Muralidhar

Associate Professor, Electrical Engg. Dept.

Muffakham Jah College of Engg. & Tech.

Hyderabad, India

muralidhareed@mjcollege.ac.in

Abstract—This paper aims to reduce the Common Mode

Voltage (CMV) in the Diode Clamped Multilevel Inverter

(DCMLI). Three phase wye connected R-L load is connected to

DCMLI. The common mode voltage exists between neutral point

of wye connected load and ground of system.CMV causes

premature failure of bearings of induction motor & is essential to

reduce.CMV is reduced in this paper by using Phase Opposition

Disposition SPWM technique. A comparative study of three, five,

seven and nine level DCMLI in terms of THD and CMV has been

presented. The effect of a passive LC filter on THD was

studied.The simulation of circuit is carried out by using

MATLAB/Simulink. Simulation result showed reduction in THD

and CMV by using POD-SPWM controlled higher level

Inverters.

Keywords—CMV,THD,POD SPWM,DCMLI

I. INTRODUCTION

Inverter converts D.C. input voltage to a.c. output

voltage of desired magnitude and frequency [1]-[4]. The two-

level inverter can create only two different output voltages

i.e.,+ V /2 or −V /2 when inverter’s D.C. input voltage is

V . The concept of Multilevel Inverter (MLI) does not depend

on just two levels of voltage to create an a.c. signal. Instead

several levels of voltages are added to each other to create a

smoother stepped waveform. High speed switching is used in

MLI [5]. MLI found its applications in industrial motor drives,

utility interfaces for renewable energy systems, flexible a.c.

transmission systems(FACTS), high voltage direct current

transmission (HVDC), and traction drives systems [6]-[9]. The

advantages of multilevel Inverters when compared with

conventional 2-level converter are less harmonic distortion in

output voltages, low dv/dt [10].CMV is less in MLI when

compared to two level VSI.CMV results in high leakage

current and premature failure of motor bearing take place so it

is required to reduce. Various modulation strategies based

methods to reduce CMV are MLI using Active Zero State

PWM (AZSPWM) [11],MLI using Remote State PWM

(RSPWM) [12],MLI using Near State PWM (NSPWM)

[13],MLI using SPWM technique[14],MLI using Space vector

modulation[15] and MLI using Modified space vector

modulation topology. Extra hardware circuitry based methods

to reduce CMV are

• Dual bridge inverter

• Four leg Inverter

• Properly designed dv/dt filter &

• Common mode chokes.

The concept of multilevel inverters (MLI) has been

introduced since mid-1970. The term multilevel coined with

the three level inverter. Afterwards, numerous multilevel

inverter topologies continue to develop, especially in the last

two decades. There are several types of multilevel Inverters.

The three main types of multilevel Inverters are Diode

Clamped Multilevel Inverter (DC-MLI), Flying Capacitor

Multilevel Inverter (FC-MLI) or Capacitor clamped MLI and

Cascaded H-bridges multilevel Inverter (CHB-MLI). First

multilevel inverter (MLI) was cascaded H bridge inverter

designed in 1975 but it found its application in 1990, therefore

DC-MLI was considered as first generation of multilevel

technology. The advantages of DC-MLI are as follows:

• Inverter efficiency is high because all devices are

switched at fundamental frequency.

• Harmonic content in output voltage is low when

compared to conventional two level inverter.

• The capacitance requirement of the inverter is

lessened due to all phases sharing a common DC

link.

• The control method is simple.

DC-MLI requires excessive clamping diodes when number of

levels is high and it is difficult to control the real power flow

of individual converter in multi converter systems. DC-MLI

founds its applications in High power medium voltage

variable speed drives, interface between HVDC transmission

line and a.c. transmission line.

In 1992, Meynard and Foch proposed flying capacitor MLI.

The structure of this inverter is similar to that of the DC-MLI

Common Mode Voltage reduction in Diode

Clamped MLI using Phase Opposition Disposition

SPWM Technique

International Conference on Electrical, Electronics, Computers, Communication, Mechanical and Computing (EECCMC)

Page 355 of 470

978-1-5386-4304-4/18/$31.00 ©2018 IEEE](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-38-320.jpg)

![except that instead of using clamping diodes, it uses capacitors

as its name implies. This topology has a ladder structure of

D.C. side capacitors, where the voltage on each capacitor

differs from that of the next capacitor. The voltage increment

between two adjacent capacitor legs gives the size of the

voltage steps in the output waveform. For, m level flying

capacitor inverter 2×(m-1) switches, (m-1) main capacitors

and (m-1)×(m-2)/2 auxiliary capacitors are required in each

leg[21].The advantages of FC-MLI are as follows:

• Large amount of storage capacitors can provide

capabilities during power outages.

• Like the Diode clamped inverter with more levels,

the harmonic content is low.

• Both real and reactive power flow can be controlled.

FC-MLI needs excessive number of storage capacitors when

number of levels is high. High level inverters are more

difficult to package with bulky power capacitors & are more

expensive, Inverter control is difficult & are expensive too.

Efficiency is reduced for real power transmission.

Fig.1. Classification of Inverters

The third topology is Cascaded H bridge multilevel

inverter. The cascaded multilevel inverter is based on the

series connection of single leg or double leg (H bridges)

inverters with separate D.C. sources. The a.c. output of each

H-bridge is connected in series such that the synthesized

output voltage is the sum of all of the individual H-bridge

outputs. For m-level inverter number of cells required is (m-

1)/2. The advantages of CHB-MLI are as follows:

• Less components are required in CHB-MLI when

compared with DC-MLI and FC-MLI to achieve

same number of voltage levels.

• In order to reduce switching losses & device stress

soft switching techniques can be used.

CHB-MLI requires separate D.C. sources for real power

conversions, there by restricting its applications.

Different modulation techniques exist to control the

output voltage of inverter. The modulating signal based

techniques are Sinusoidal PWM, Third harmonic injection

PWM,Space vector PWM and Modified space vector

PWM.The Multicarrier PWM techniques are Phase

Disposition PWM,Phase Opposition Disposition

PWM,Alternative Phase Opposition Disposition PWM.

Fig.2. Classification of Modulation Techniques

In this paper,Common Mode Voltage and Total Harmonic

Distortion reduction in DC-MLI using Phase Opposition

Disposition Sinusoidal Pulse Width Modulation is presented.

II. COMMON MODE VOLTAGE

The common mode voltage is defined as the potential of

the star point of the load with respect to the center of the D.C.

bus of the inverter (or) The common mode voltage (CMV) of

the three-phase system is defined as the voltage potential

difference between the star point of the load network and the

mid-point of the D.C. link capacitors (or) Common mode

voltage is voltage between neutral point of star connected load

and system ground. Mathematical expression for CMV is

shown in equation (1).

CMV = V = (1)

Where V ,V , V are the voltages between ground to phase.

V is voltage between neutral of motor and system ground. A

generalized drive system is represented in fig. 3.

Fig.3. A generalized drive system

International Conference on Electrical, Electronics, Computers, Communication, Mechanical and Computing (EECCMC)

Page 356 of 470](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-39-320.jpg)

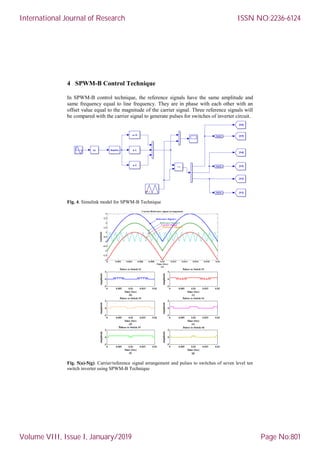

![Table 2 shows the CMV and %THD for two level VSI, 3, 5, 7

and 9 level Diode clamped Inverter using Phase Opposition

Disposition SPWM technique with and without LC filter.

TABLE 2: CMV AND %THD VALUES FOR POD SPWM CONTROLLED

DCMLI

2-level

VSI

3-Phase POD SPWM Controlled DCMLI

3-level 5-level 7-level 9-level

CMV

(V)

145.2 44.3 18.76 12.56 12.20

THD

(%)

Without

filter

97.63 70.46 35.65 22.46 13.86

With

filter

28.02 21.79 11.21 7.19 4.56

Variation of CMV and % THD with level of Inverter is shown

in fig. 12.

Fig.12.Variation of CMV and THD with level of Inverter

From the fig. 12 it can be noticed that CMV and %THD

decreases with increase in level of the inverter as increase in

level improves the nature of output voltage waveform,

approaching to sinusoidal shape which in turn reduces lower

order harmonics. The number of steps in the output voltage

increases as the level increases which reduces rate of rise of

voltage.CMV and %THD reduces as step size reduces.

VII. CONCLUSION

POD SPWM controlled DCMLI for three, five, seven and nine

level is simulated in Matlab/Simulink software.Table-2 clearly

shows that two level inverter produces high CMV and THD

which causes high leakage current and premature failure of

motor bearing . A comparative study of three level, five level,

seven level and nine level DCMLI in terms of THD and CMV

shows as level of the inverter increases CMV and %THD

decreases. The simulation output gives a conclusion that by

employing POD SPWM technique to DCMLI, CMV can be

reduced. POD SPWM controlled DCMLI also reduces dv/dt

in its output voltage and therefore CMV and thus flow of

leakage current in motor bearing reduced.

APPENDIX

Parameters Used for Simulation:

1. Input D.C.Voltage V =440V

2. Load R=100 Ohms, L=50e-3 Henry

3. Fundamental frequency=50Hz

4. Carrier frequency f = 1000Hz

5. Amplitude Modulation Index, m = 0.8

6. Frequency Modulation Index, m = 20

7. LC filter: L=5.7e-3 Henry, C=3.45e-6 Farad

REFERENCES

[1] G. Prem Sunder, B. Shanthi, A. Lamehi Nachiappan and S. P. Natrajan,

“Performance Analysis of modified CHB MLI using various carrier

modulation schemes”, IJESA, vol. 3, no. 5, (2013), pp. 310-316.

[2] F. Z. Peng and J. S. Lai, “Multilevel converters, A new breed of power

Electronics converters”, IEEE Trans Industries Application, vol. 32,

(1996), pp. 509-517.

[3] K. Jagdish, “THD Analysis for different levels of cascade multilevel

inverter for industrials applications”, IJETAE, (2012), pp. 20-30.

[4] M. Kavitha, A. Arunkumar, N. Gokulnath and S. Arun, “New cascaded

H-bridge multilevel inverter topology with reduced number of switches

and sources”, JEEE, vol. 2, no. 6, (2012), pp. 26-36.

[5] D. Grahame Holmes, Thomas A. Lipo, “Pulse Width Modulation For

Power Converters”, WILEY INTERSCIENCE,2003.

[6] Michail Vasiladiotis, “Analysis, Implementation and Experimental

Evaluation of Control Systems for a Modular Multilevel Converter”,

Master Thesis, KTH-EME, 2009.

[7] Zhang Jingzhe, “Analysis of a Cascade Voltage Source Multilevel

Converter for a High Power Motor Drive”,Master Thesis, KTH-EME,

2008.

[8] Cristian Sandu, Nicoleta Carnu and Valentin Constantin Costea,

“Medium Voltage Modular Multi-Level Inverter”, Master Thesis,

Aalborg University, 2008.

[9] A. Antonopoulos, L Ängquist and H.P. Nee, “On Dynamics and

Voltage Control of the Modular Multilevel Converter”, European Power

Electronics Conference (EPE), Barcelona, Spain, September 8-10, 2009

[10] A. Mokhberdoran and A. Ajami, “Symmetric and Asymmetric Design

and Implementation of New Cascaded Multilevel Inverter Topology”,

IEEE Transactions on Power Electronics, vol. 29, no. 12, pp. 6712-6724,

2014.

[11] Y.S. Lai and F.S. Shyu, “Optimal common-mode voltage reduction

PWMtechnique for inverter control with consideration of the dead-time

effects-part I:basic development,” IEEE Trans. on Industry Applications,

vol 40, pp.1605-1612, November/December 2004.

[12] M. Cacciato, A. Consoli, G. Scarcella, and A. Testa, “Reduction of

commonmode currents in PWM inverter motor drives,” IEEE Trans. on

Industry Applications, vol. 35, pp. 469-476, March/April 1999.

[13] E. Ün and A.M. Hava, “A near state PWM method with reduced

switching frequency and reduced common mode voltage for three-phase

voltage source inverters,” in Proc. IEEE-IEMDC’07, 2007, pp. 235-240.

[14] P. G. Shewane, S. Gaigowal, B. Rane, “Multicarrier Based SPWM

Modulation for Diode Clamped MLI to reduce CMV and THD”,

Power,Automation and Communication [INPAC-2014], International

Conference at Amravati on 6-8 OCT.2014, pp. 50-

54,DOI:10.1109/INPAC.2014.6981134, IEEE.

[15] Sk. Moin Ahmed, Haitham Abu-Rub, Zainal Salam, “Common Mode

Voltage Elimination in a Three-to-Five-Phase Dual Matrix Converter

Feeding a Five-Phase Open-End Drive Using Space-Vector Modulation

Technique”,IEEE TRANSACTIONS ON INDUSTRIAL

ELECTRONICS,VOL. 62, NO. 10, OCTOBER 2015.

International Conference on Electrical, Electronics, Computers, Communication, Mechanical and Computing (EECCMC)

Page 364 of 470](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-47-320.jpg)

![www.ijcrt.org © 2018 IJCRT | Volume 6, Issue 2 April 2018 | ISSN: 2320-2882

IJCRT1812942 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 579

Common Mode Voltage reduction in Diode Clamped

MLI using Alternative Phase Opposition Disposition

SPWM Technique

1

Mohd Esa, 2

J.E.Muralidhar

1

M.E. Student, 2

Associate Professor

1,2

Electrical Engineering Department

1, 2

Muffakham Jah College of Engineering and Technology, Hyderabad, India

Abstract: The main objective of this paper is to reduce the Common Mode Voltage (CMV) in the Diode Clamped Multilevel Inverter

(DCMLI).Three phase Y-connected RL load is connected to DCMLI. The common mode voltage exists between neutral point of Y-

connected load and system ground.CMV causes premature failure of bearings of induction motor and is essential to reduce. In this

paper, Alternative Phase Opposition Disposition SPWM technique is used to reduce common mode voltage. Two level, five level,

seven level and nine level DCMLI are compared in terms of THD and CMV.The effect of a passive LC filter on THD was studied.

The simulation of circuit is carried out by using MATLAB/Simulink. Simulation result portrays reduction in THD and CMV by using

APOD-SPWM controlled higher level Inverters.

IndexTerms - CMV, THD, APOD SPWM, DCMLI

I. INTRODUCTION

CMV is define as voltage between neutral point of the load and the dc midpoint or the voltage between neutral point of load and the

system ground or the common mode voltage is defined as the potential of the star point of the load with respect to the center of the D.C.

bus of the inverter (or) the common mode voltage (CMV) of the 3-phase system is defined as the voltage potential difference between

the star point of the load network and the mid-point of the D.C. link capacitors[1].

CMV= ∑ (1)

Where are the voltages between ground to phase.CMV is zero in purely sinusoidal three phase system but VSI is non-

pure sinusoidal system thus it develops CMV. CMV results in high leakage current and premature failure of motor bearing so it is

required to reduce [2], [3]. Some modulation techniques based approaches to reduce CMV are MLI using SPWM technique, MLI

using Space Vector PWM technique, MLI using Modified space vector modulation technique, predictive current control method, on

zero state modulation techniques. In this paper, APOD- SPWM is used to reduce common mode voltage.

Fig.1.Schematic of single pole of MLI by a

switch [5]

Fig.2.Typical output voltage of 5

level MLI [5]](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-48-320.jpg)

![www.ijcrt.org © 2018 IJCRT | Volume 6, Issue 2 April 2018 | ISSN: 2320-2882

IJCRT1812942 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 580

The idea of multilevel inverters has been introduced in 1975 with invention of cascaded H-Bridge MLI.The term multilevel began

with 3- level inverter. Afterwards numerous multilevel inverter topologies have been developed .Three different MLI topologies that

have been proposed are diode clamped or neutral point clamped, flying capacitor and cascaded H-Bridge or multicell MLI [4]. In

addition, several control strategies have been developed. The series connected capacitors constitute the energy tank for the inverter,

providing some nodes to which MLI can be connected. Each capacitor has the same voltage ,which is given by

(2)

Where m denotes the number of levels. The term level refers to number of nodes to which the inverter can be accessible. An m-level

inverter needs m-1 capacitors. Figure 2 shows the schematic of a pole in MLI.Pole is regarded as a single-pole, multi-throw switch.

Desired output can be obtained by connecting the switch to one node at a time.

Different modulation techniques exist to trigger switches of inverter circuit. The commonly used modulation techniques are as

follows

Sinusoidal pulse width modulation (SPWM) [6]

Third harmonic PWM (THPWM)

Space vector PWM (SVPWM) [7]

Modified Space vector PWM (MSVPWM)

The most popular method of controlling inverter‟s output voltage is SPWM technique.SPWM is a carrier based pulse width

modulation method in which predefined modulation signal is used to determine output voltages. Sinusoidal modulation signal is used

in SPWM technique. The gating signal in SPWM is generated by comparing a reference signal of sine shape with a triangular carrier

wave.

Fig.3.Comparision of reference and carrier signal in SPWM generation

The width of each pulse varied proportionally to amplitude of a sine wave. The output frequency of a inverter can be found by using

the frequency of reference signal. The rms output voltage can be controlled by modulation index and intern modulation index is

controlled by peak amplitude.SPWM method results in reduction of THD for output voltage.SPWM technique is effective modulation

technique and it does not require any additional components and eliminates lower order harmonics easily. Carrier based SPWM

techniques are classified as follows

Single carrier based SPWM technique

Multi carrier based SPWM technique

Single carrier SPWM technique is used for 2-level inverter whereas multi carrier SPWM technique is used in Multi-level

inverters. Multi carrier SPWM technique is further classified as follows

Phase shift SPWM technique

Level shifted SPWM technique

Hybrid SPWM technique

Level shifted SPWM technique is further classified as follows

Phase Disposition (PD)

Phase Opposition Disposition (POD)

Alterative Phase Opposition Disposition (APOD)

Alternative phase opposition disposition SPWM is used to reduce common mode voltage in Diode clamped MLI.](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-49-320.jpg)

![www.ijcrt.org © 2018 IJCRT | Volume 6, Issue 2 April 2018 | ISSN: 2320-2882

IJCRT1812942 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 581

II. DIODE CLAMPED MULTILEVEL INVERTER

Diode clamped Inverter (DC-MLI) is also known as neutral point clamped inverter (NPC-MLI). A m level diode clamped inverter

typically consists of (m-1) capacitors on the D.C. bus and produces m levels on the phase voltage. The m- level inverter leg requires (m-

1) capacitors, 2× (m-1) switching devices and (m-1) × (m-2) clamping diodes [8].

Fig.4.Three phase 5 level DCMLI

For one phase, steps to synthesize the five level voltages are as follows.

1. Turn on all upper half switches of Limb-A i.e., from SW1 to SW4 for an output voltage level

2. Turn on three upper switches of Limb-A i.e., SW2 to SW4 and one lower switch of Limb-A i.e., SW5 for an output voltage

level

3. For an output voltage level ,turn on two upper switches SW3 and SW4 of Limb-A and two lower switches SW5 and

SW6 of Limb-A.

4. Turn on one upper switch SW4 of Limb-A and three lower switches SW5 to SW7 of Limb-A for an output voltage

level .

5. Turn on all lower half switches from SW5 to SW8 of Limb-A for an output voltage level

Table 1: Switching states of five level diode clamped inverter for phase A

Switching States Output

voltageSW1 SW2 SW3 SW4 SW5 SW6 SW7 SW8

High High High High Low Low Low Low Vdc/2

Low High High High High Low Low Low Vdc/4

Low Low High High High High Low Low 0

Low Low Low High High High High Low -Vdc/4

Low Low Low Low High High High High -Vdc/2

Seven level and nine level diode clamped inverters can also be presented in same manner as five level DCMLI](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-50-320.jpg)

![www.ijcrt.org © 2018 IJCRT | Volume 6, Issue 2 April 2018 | ISSN: 2320-2882

IJCRT1812942 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 582

III. ALTERNATIVE PHASE OPPOSITION DISPOSITION SPWM STRATEGY

In APOD-SPWM technique the carrier signal of same amplitude are phase displaced from each other by 180° from its neighboring

carrier signals, This carriers are compared with sinusoidal signal for producing pulse signals to trigger gates of switches used in

DCMLI.For m-level output, (m-1) carrier signals are phase disposed by 180 degrees to its neighboring carrier waveform [9]. Fig. 6(a),

6(b), and 6(c) shows the carrier arrangement for APOD SPWM controlled 5, 7 and 9 level DCMLI respectively

Fig. 5. APOD-SPWM technique for triggering switches of five level diode clamped inverter (Phase A)

The amplitude modulation index and frequency ratio are mathematically shown in equations (3) and (4) respectively.

(3)

Where peak to peak amplitude of reference waveform or modulating signal, is peak to peak amplitude of individual carrier

frequency, m is output level of inverter.

Where frequency of carrier signal & is frequency of modulating signal.

Fig. 6(a).Carrier arrangement for APOD SPWM controlled 5-

level DCMLI ( and =20).

Fig. 6(b).Carrier arrangement for APOD SPWM controlled 7-

level DCMLI ( and =20).

Fig. 6(c).Carrier arrangement for APOD SPWM controlled 9-level DCMLI ( and =20).](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-51-320.jpg)

![www.ijcrt.org © 2018 IJCRT | Volume 6, Issue 2 April 2018 | ISSN: 2320-2882

IJCRT1812942 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 587

V.CONCLUSION

APOD SPWM controlled DCMLI for five, seven & nine level is simulated in Matlab/Simulink software. It is cleared from fig. 12

that CMV and %THD decreases with increase in level of the inverter. Increase in level improves the nature of output voltage waveform,

approaching to sine shape which in turn lessens lower order harmonics. The number of steps in the output voltage increases as the level

increases which reduces rate of rise of voltage.CMV and %THD reduces as size of step reduces.

REFERENCES

[1] E. Un and A. M. Hava, “A Near State PWM Method with Reduced Switching Losses and Reduced Common Mode Voltage for

3-Phase Voltage Source Inverters,” Industry Applications, I.E.E.E. transactions on, vol. 45, pp. 782-793, 2009

[2] Min Zhang, “Investigation of Switching Schemes for 3-phase Four Leg Voltage Source Inverters”, A thesis submitted for the

degree of Doctor of Philosophy June, 2013, School of Electrical and Electronic Engineering,Newcastle University

[3] Anuradha V.Jadhav and Mrs.P.V.Kapoor, “Reduction of Common Mode Voltage using Multilevel Inverter”, Energy Efficient

Technologies for Sustainability [ICEETS],pp.586-590,06 October 2016,DOI: 10.1109/ICEETS.2016.7583822,I.E.E.E.

[4] T. Cunnyngham. Cascade Multilevel Inverters for Hybrid-Electric Vehicle Applications with Variant DC Sources. Master‟s

thesis, The University of Tennessee, 2001.

[5] Muhammad H. Rashid,“Power Electronics-Circuits, Devices and Applications” Pearson Education Incorporated, 2005.

[6] P. G. Shewane, S. Gaigowal, B. Rane, “Multicarrier Based SPWM Modulation for Diode Clamped MLI to reduce CMV and

THD”, Power,Automation and Communication [INPAC-2014], International Conference at Amravati on 6-8 OCT.2014, pp. 50-

54,DOI:10.1109/INPAC.2014.6981134, IEEE.

[7] Sk. Moin Ahmed, Haitham Abu-Rub, Zainal Salam, “Common Mode Voltage Elimination in a Three-to-Five-Phase Dual Matrix

Converter Feeding a Five-Phase Open-End Drive Using Space-Vector Modulation Technique”,IEEE TRANSACTIONS ON

INDUSTRIAL ELECTRONICS,VOL. 62, NO. 10, OCTOBER 2015.

[8] A.Nabae, I. Takahashi, H.Akagi„A new Neutral Point CIamped PWM Inverter‟‟ I.E.E.E. transactions on Industry applications, Vol.

IA-I7, No.5,pp.518-52 September/October,1981.

[9] McGrath, B.P.; Holmes, D.G.; “Multicarrier PWM strategies for Multilevel Inverters,” Industrial Electronics, I.E.E.E. transactions,

vol.49, no.4, pp. 858- 867, August 2002 ,DOI:10.1109/TIE.2002.801073](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-56-320.jpg)

![Elimination of Common Mode Voltage in

Neutral Point Clamped MLI using ZCM-SPWM

Technique

Mohd Esa

M.E. Student, EED

M.J.C.E.T., Hyderabad

zmohdesa@gmail.com

Ahmed Maaz

Assistant Professor, EED

N.S.A.K.C.E.T., Hyderabad

hmdmaaz58@gmail.com

Mohd Abdul Rahman Uzair

Associate Professor, EED

N.S.A.K.C.E.T., Hyderabad

as_uzair2003@yahoo.co.in

Abstract— The main aim of this paper is to eliminate the

Common Mode Voltage (CMV). CMV is the voltage between

neutral point of a Y connected RL load & ground of the system.

This paper focuses on the CMV in inverter circuits. The effects of

this voltage is damage to bearings of motor, unexpected ground

fault trips, erratic behavior of VFDs, premature motor insulation

failure and cable damage.CMV is having drawbacks such as

leakage current flowing through the stray capacitors between

motor windings and frame, electromagnetic interference, shaft

voltages, bearing currents and break down of motor

insulation.CMV can be reduced by external circuit methods such

as use of common mode choke, properly designed dv/dt filter,

isolation transformer, active filters, passive filters, dual bridge

inverter and four leg inverters. In this paper, CMV is eliminated

in 3-level Neutral Point Clamped (NPC) inverter using Zero

Common Mode (ZCM) SPWM Technique. The simulation of

circuit is carried out by using MATLAB/Simulink software.

Keywords— NPC-MLI, ZCM-SPWM, CMV

I. INTRODUCTION

he conventional PWM voltage source inverters have

least devices, simple circuit topology & control. Their

main drawbacks are existence of harmonics close to the

switching frequency [1]. They also have a main problem of

CMV which gives rise to shaft voltages & bearing currents

[2], [3]. Bearing currents and shaft voltages have been

recognized since 1924.The main cause for this was

asymmetric flux distribution inside the motor which leads to

an induced voltage across the rotor shaft [4],[5]. At low

frequency, chances of occurrence of this fault is very less.

Before 1980 it was supposed that the bearing current problems

are mainly due to electromagnetic induction. It becomes a

prominent problem after the application of recently developed

semiconductor devices in drives [6].For better operation of

induction motor CMV must be reduced. It is very important to

reduce CMV itself or to limit this voltage to within certain

bounds. Some of the approaches to reduce CMV are

application of different types of filters [7], dual bridge

inverters [8], four leg inverters [9], by improving modulation

techniques [10], [11] etc. A multilevel inverter can reduce as

well as eliminate the CMV. The concept of multilevel

originated with the three-level converter which is often known

as neutral-point converter. Here converter mentions to the

power flow in both the directions i.e. from dc to ac called as

inverter and from ac to dc called as rectifier. The

commercially existing multilevel inverter topologies are diode

clamped (DC-MLI) or neutral point clamped (NPC-MLI),

flying capacitor or capacitor clamped (CC-MLI) & Cascaded

H bridge inverter or multicell inverter. Though cascade

multilevel inverter was designed in 1975 it found its

application in 1990, therefore NPC-MLI was considered as

first generation of multilevel technology. NPC-MLI was the

first one that made it possible to produce an output voltage

from only single dc source. The efficiency of NPC-MLI is

high because all devices are switched at the fundamental

frequency & when number of levels is high enough, harmonic

content is low enough to avoid need of filters but excessive

clamping diodes are required when numbers of levels are high.

Capacitor clamped multilevel inverter is an alternative to

NPC-MLI.Capacitor clamped MLI uses capacitors for

clamping. It is easier to increase number of levels in CC-MLI

than the NPC-MLI that is why it is progressively used in

numerous high power applications. For x level, capacitor

clamped inverter consists of 2× (x-1) switches, (x-1) main

capacitors and (x-1) × (x-2)/2 auxiliary capacitors are essential

in each leg. In CC-MLI both real and reactive power flow can

be controlled but switching frequency and switching losses are

high for real power transmission [12].In multicell inverter

topology, ac output of each H-bridge is connected in series

such that the synthesized output voltage waveform is the sum

of all of the individual H-bridge outputs. For x level, inverter

number of cells required is (x-1)/2.Clamping diodes or

capacitors are not required thus components used are less in

this topology but separate dc sources are required for each H-

bridge.

To control the output voltage of inverter different

modulation strategies exists. These strategies can be classified

according to fundamental switching frequency & high

switching frequency. Modulation techniques based on

fundamental switching frequencies are selective harmonic

elimination & space vector control. High switching based

methods are Sinusoidal Pulse Width Modulation (SPWM)

[13], Selective Harmonic Elimination (SHE-PWM), Space

Vector Modulation (SVM). These PWM techniques are easy

T](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-57-320.jpg)

![to implement and they reduce lower order harmonics.SPWM

is simplest of all the above control strategies.Schonung and

stemmler introduced SPWM Technique in 1964.SPWM

technique does not require any calculations and is most

popular in industrial applications.

Multi carrier techniques based on classical SPWM has

been developed. Phase shifting and level shifting are major

techniques of multicarrier SPWM. The multi carrier based

high frequency techniques are a) Phase disposition (PD-

SPWM) b) Phase Opposition Disposition (POD-SPWM) c)

Alternate Phase Opposition Disposition (APOD-SPWM) d)

Phase Shift (PS-SPWM) e) Alternate Phase Shift (APS-

SPWM) f) Carrier Overlap (CO-SPWM) g) Variable

Frequency (VF-SPWM) h) Alternate Variable Frequency

(AVF-SPWM) [14].These strategies are useful to reduce CMV

in multilevel inverters.

Dual bridge inverter topology has proved to be effective

in eliminating the CMV and motor bearing currents, as well as

in reducing EMI.Dual bridge inverter approach is based on

feeding a suitably connected double winding motor by two

parallel inverter units having opposite polarities. Size and cost

are disadvantage for this CMV reduction technique.

Fig.1. A 3-level NPC-MLI

Control strategy based CMV reduction techniques are

multilevel inverter using SPWM technique, multilevel inverter

using space vector technique, multilevel inverter using

modified space vector modulation & multilevel inverter using

active common mode elimination modulation technique. In

this paper, ZCM-SPWM technique is used to eliminate CMV

II. OPERATION OF 3-LEVEL NPC-MLI

NPC-MLI was proposed by Nabae et al., in 1981.A x

level neutral point clamped inverter typically consists of (x-1)

capacitors on the dc bus and produces x levels on the phase

voltage. The x- level inverter leg requires 2× (x-1) switching

devices and (x-1) × (x-2) clamping diodes [15].

TABLE I: SWITCHING STATES OF THREE LEVEL NEUTRAL POINT

CLAMPED INVERTER

Switching States Output

voltageSW1 SW2 SW3 SW4

H H L L /2

L H H L 0

L L H H -

It needs four switches in each leg. There are total twelve

switches in three phase three level NPC-MLI.SW1 and SW2

are switches in upper half of the first leg and SW3 and SW4

are the switches in lower half of the first leg and it has two

clamping diodes in each leg. Main capacitors required are two.

The operation of three level neutral point clamped inverter

(Phase R) is as follows. When switch SW1 and SW2 are high,

output voltage is /2.When SW2 and SW3 are high, output

voltage is zero. When SW3 and SW4 are high, output voltage

is /2 [16].

III. ZCM-SPWM TECHNIQUE

This technique employs one triangle carrier signal & three

balanced sinusoidal modulation signal. At first, two of the

three modulation signals are compared with the carrier signal

resulting in two intermediate PWM signals for one phase.

Then, subtraction of this two intermediate signals produces the

PWM signal for the same phase. The same algorithm should

be applied to the other two phases. It is important to note that

this SPWM scheme guarantees that the switching happens

only among those states with zero common-mode voltage.

Fig.2.Switching states of three level NPC-MLI

A 3-level NPC-MLI has 27 states. Among this states there are

seven states that will result in zero common mode voltages.

They are (PON), (PNO), (OPN), (NOP), (NPO), (ONP) and

(OOO).It is obvious that common mode voltage of NPC-MLI

is zero for all the above seven states. So by limiting the

switching states only to those listed above, a 3-level NPC-MLI

will not guarantee CMV [17].

To summarize we have the following equations](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-58-320.jpg)

![Fig.5.Phase voltage of 3-level NPC-MLI Fig.6.Line voltage of 3-level NPC-MLI

Fig.7.CMV output using ZCM-SPWM Technique

Fig.5. shows phase voltage of three level neutral point

clamped inverter and Fig.6. presents line voltage of three level

neutral point clamped inverter using ZCM-SPWM

technique.CMV using ZCM-SPWM technique is shown in

Fig.7.

V. CONCLUSION

A three phase three level neutral point clamped inverter is

implemented in MATLAB/Simulink software using zero

common mode-sinusoidal pulse width modulation technique

for RL load. Simulation result shows that by using ZCM-

SPWM technique CMV is eliminated.

ACKNOWLEDGEMENT

Corresponding author Mohd Esa would like to extend his

gratitude and thanks to Mr.J.E.Muralidhar, Associate

Professor, EED, MJCET for his guidance, motivation, creative

ideas and support.

REFERENCES

[1] G.Bhuvaneswari and Nagaraju, “Multi-Level Inverters –

A Comparative Study,” IETE Journal of Research,

Vol.51, No. 2,pp.141-153, March-April 2005.

[2] Jay M.Erdman,R.J.Kerkman,D.W.Schlegel and

G.L.Skibinski , “Effect of PWM Inverters on AC Motor

Bearing currents and Shaft Voltages,” IEEE Transactions

on Industry Applications, Vol.32, No. 2 , pp.250- 259 ,

March/April 1996.

[3] Doyle Busse, Jay Eradman, R.J.Kerkman, Dave Schlegel

and Gary Skibinski , “System Electrical Parameters and

Their Effects on Bearing Currents,” IEEE Transactions on

Industry Applications ,Vol- 33, No.2, pp. 577-583,

March/April1997.

[4] S.Chen and T.A.Lipo, “Sources of Induction Motor

Bearing Currents Caused by PWM Inverters”, IEEE

Transactions on Energy Conversio, Vol. 11, No. 1, pp.

25-32, Mar. 1996.

[5] Doyle Busse, Jay Erdmann, R.J.Kerkman, Dave Schlegel

and Gary Skibinski, “Bearing Currents and Their

Relationship to PWM Drives” , IEEE Transactions on

Power Electronics, Vol. 12, N0. 2, pp.243-252, Mar.1997.

[6] S.Chen, T, A.Lipo and D.Fitzgerald, “Modeling of Motor

Bearing Currents in PWM Inverter Drives”, IEEE

Transactions on Industry Applications, Vol. 32, No.6, pp.

1365-1370, November/December, 1996.](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-60-320.jpg)

![[7] H.Akagi and S.Tamura , “ A Passive EMI Filter for

Eliminating both Bearing Current and Ground Leakage

Current from an Inverter-Driven Motor, ” IEEE

Transactions on Power Electronics Vol.21,No.5 ,

pp.1459-1469 ,September 2006.

[8] R.S. Kanchan, P.N. Tekwani, M.R. Baiju, K. Gopakumar

and A. Pittet, “Three-level Inverter Configuration with

Common Mode Voltage Elimination for Induction Motor

Drive,” IEE Proc.- Electr. Power Appl., Vol. 152, No. 2,

pp.261-270, March 2005

[9] Alexander L. Julian, Giovanna Oriti, and Thomas A.

Lipo, “Elimination of Common-Mode Voltage in Three-

Phase Sinusoidal Power Converters,” IEEE Transactions

on Power Electronics Vol.14,No.5 , pp.982-989

,September 1999.

[10]M.M.Renge and H.M.Suryawanshi , “ Multilevel Inverter

to Reduce Common Mode Voltage in AC Motor Drives

Using SPWM Technique.” pp.21-27,Journal of Power

Electronics, Vol. 11, No. 1, January 2011

[11]M.M.Renge and H.M.Suryawanshi , “Five-Level Diode

Clamped Inverter to Eliminate Common Mode Voltage

and Reduce dv/dt in Medium Voltage Rating Induction

Motor Drives.”, IEEE Transactions on Power Electronics

,Vol.23 , No. 4 , pp.1598-1607,July,2008.

[12]Mohd Esa, Mohd Abdul Muqeem Nawaz and Syeda

Naheed, " Harmonic Analysis of Three level Flying

Capacitor Inverter ", International Research Journal of

Engineering and Technology (IRJET), vol. 04, no. 10, pp.

1687-1694, 2017.

[13]Mohd Esa and Mohd Abdul Muqeem Nawaz, "THD

analysis of SPWM & THPWM Controlled Three phase

Voltage Source Inverter", International Research Journal

of Engineering and Technology (IRJET), vol. 04, no. 10,

pp. 391-398, 2017.

[14]Mohd Esa and J.E.Muralidhar, "Investigation of

Common Mode Voltage in 5-level Diode Clamped MLI

using carrier based SPWM Techniques", International

Journal of Creative Research Thoughts (IJCRT), ISSN:

2320-2882, Volume.6, Issue 1, Page No pp.395-399,

February 2018

[15]M. Esa and J. E. Muralidhar, "Common Mode Voltage

reduction in Diode Clamped MLI using Phase Disposition

SPWM Technique," 2018 4th International Conference on

Electrical Energy Systems (ICEES), Chennai, India, 2018,

pp. 279-289. doi: 10.1109/ICEES.2018.8442411

[16]Mohd Esa and J.E.Muralidhar, "Common Mode

Voltage reduction in Diode Clamped MLI using

Alternative Phase Opposition Disposition SPWM

Technique", International Journal of Creative Research

Thoughts (IJCRT), ISSN: 2320-2882, Volume.6, Issue 2,

Page No pp.579-587, April-2018.

[17] Haoran Zhang,Annette von Jouanne,Shaoan Dai,Alan

k.Wallace and Fei Wang,”Multilevel Inverter Modulation

Schemes to Eliminate Common-Mode Voltages”,

IEEE Transactions on industry applications,vol.

36,no.6,November/December 2000.](https://image.slidesharecdn.com/ilovepdfmerged40-200326112403/85/Multilevel-Inverter-and-Multipliers-61-320.jpg)

![www.ijcrt.org © 2017 IJCRT | National Conference Proceeding NTSET Feb 2018 | ISSN: 2320-2882

National Conference On Trends In Science, Engineering & Technology by Matrusri Engineering College & IJCRT

IJCRTNTSE081 International Journal of Creative Research Thoughts (IJCRT) www.ijcrt.org 395

INVESTIGATION OF COMMON MODE

VOLTAGE IN 5-LEVEL DIODE CLAMPED MLI

USING CARRIER BASED SPWM TECHNIQUES

Mohd Esa1

, J.E.Muralidhar2

1

M.E Student, Department of EEE, MJCET, Hyderabad

2

Associate Professor, Department of EEE, MJCET, Hyderabad

1

zmohdesa@gmail.com

Abstract: The main aim of this paper is to investigate the Common Mode Voltage (CMV) and Total Harmonic Distortion (THD) in

five level Diode Clamped Inverter using Carrier based SPWM techniques. The common mode voltage exists between neutral point of

star connected load and system ground. Various Carrier based SPWM techniques used to analyze CMV and THD in this paper are

Phase Disposition (PD) strategy, Phase Opposition Disposition (POD) strategy, Alternative Phase Opposition Disposition (APOD)

strategy, Carrier Overlap Phase Disposition (COPD) Strategy, Carrier Overlap Phase Opposition Disposition (COPOD) strategy and

Carrier Overlap Alternative Phase Opposition Disposition (COAPOD) strategy.RL load is connected to inverter circuit for analysis

purpose and Simulation is performed using MATLAB/Simulink Software.

IndexTerms: CMV, DCMLI, SPWM Techniques

I. INTRODUCTION

Common mode voltage is the voltage between neutral point of load and system ground [1] (or) voltage between star point of load

and D.C. midpoint (or) The common mode voltage (CMV) of the three-phase system is defined as the voltage potential difference

between the star point of the load network and the mid-point of the D.C. link capacitors[2].CMV always exists in PWM converters

regardless of number of levels and legs because of its switching operation. The high frequency and high amplitude CMV produced by

PWM inverter causes common mode current (CMC) via parasitic capacitor components between converter, loads, cables and ground

respectively. This CMC could be a source of consequent electromagnetic interference (EMI) noise & it may result in mal operation of

converter control system [3].CMV produced by PWM inverters induces shaft voltages on the rotor, when this shaft voltage exceeds

voltage limit of the lubricant in the bearings, results in large bearing currents, and this cause’s premature failure of bearings of

induction motor [4]. Multilevel inverter is one of the options to reduce this problem [5]. This paper is an attempt to investigate CMV

in 5-level Diode clamped Inverter using carrier based SPWM techniques.