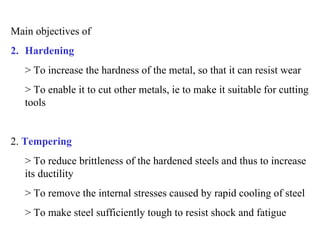

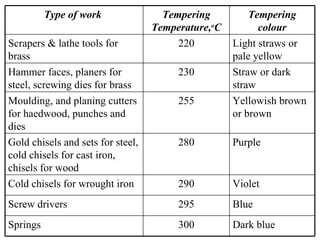

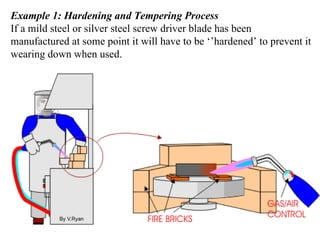

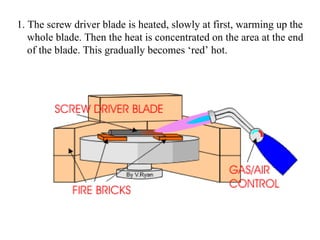

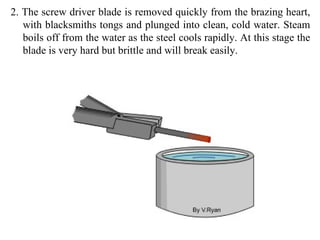

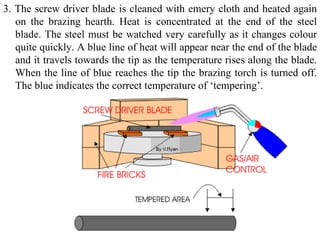

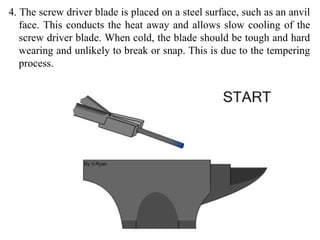

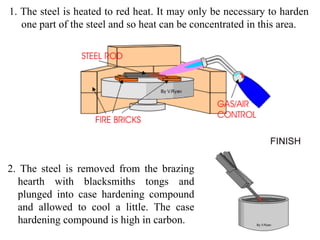

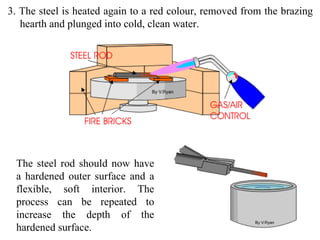

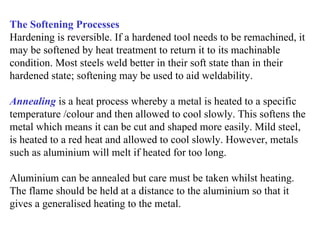

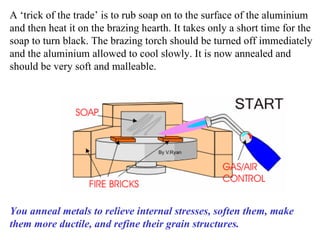

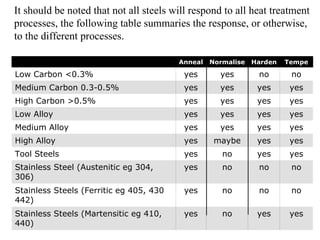

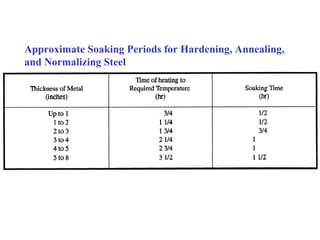

This document describes various heat treatment processes and their purposes. It explains processes like tempering, annealing, normalizing and hardening. Quenching involves rapidly cooling steel above its transformation temperature to produce martensite and increase hardness. Tempering reduces brittleness and stresses caused by quenching. Annealing softens metals by slowly cooling after heating. Normalizing heats steel to a higher temperature than annealing before air cooling to reduce stresses. The document provides examples of applying hardening and case hardening processes and recommends heat treatments for different steel types based on required properties.