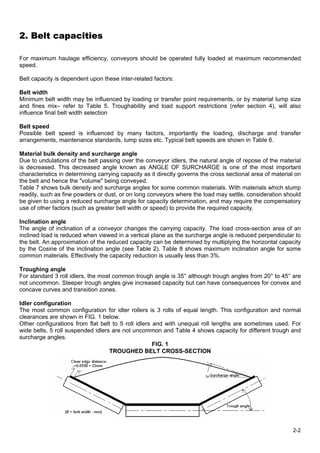

This conveyor handbook provides information on belt materials and design considerations for conveyor systems. It discusses reinforcement fabrics and cover compounds used in belt construction and their properties and applications. The handbook also addresses topics such as belt capacities and power requirements, carcass selection, cover selection, pulley diameters, design considerations, and data on solid woven and steel cord belting. Users can find guidance on selecting the proper belt specifications and designing conveyors.