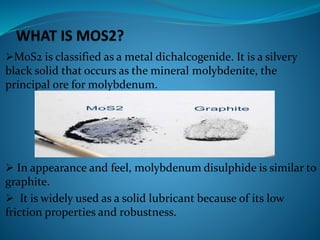

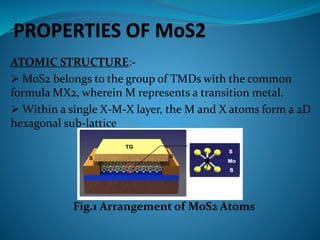

Rahul Raghvendra's seminar discussed molybdenum disulfide (MoS2), a 2D semiconductor material that can potentially replace silicon. MoS2 has desirable properties such as a tunable bandgap, high mobility, flexibility and transparency. The seminar covered MoS2's atomic structure, electrical properties, fabrication methods and applications in sensors, memory devices and flexible electronics. Challenges include controlling the number of MoS2 monolayers deposited and developing devices compatible with plastic substrates.

![[1]. MECHANICAL EXFOLIATION TECHNIQUE:-

Single and multilayer MoS2 films are deposited onto

Si/SiO2 using the mechanical exfoliation technique.

The films were then used for the fabrication of field-

effect transistors.

These FET devices can be used as gas sensors to

detect nitrous oxide (NO).](https://image.slidesharecdn.com/seminar-150324130659-conversion-gate01/85/MoS2-14-320.jpg)