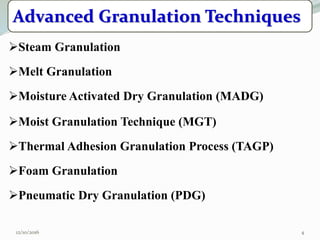

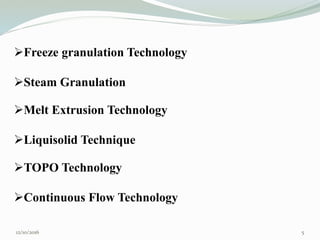

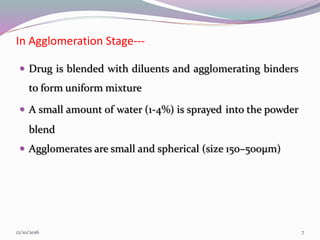

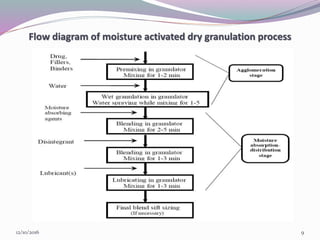

This presentation discusses moisture activated dry granulation technology (MADG). MADG is an advanced granulation technique that uses moisture to activate granule formulation but does not require heat drying. The presentation outlines the stages of MADG, including wet agglomeration where the powder blend is mixed with a small amount of water, and moisture absorption where moisture absorbents are added to redistribute moisture in the mixture and dry it. The presentation notes advantages of MADG such as short processing time and suitability for continuous processing, but also disadvantages such as difficulty developing formulations for moisture sensitive drugs or those with high drug loading.