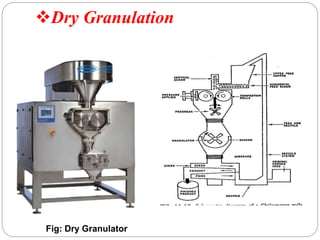

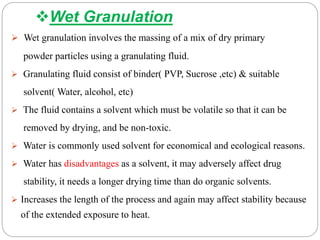

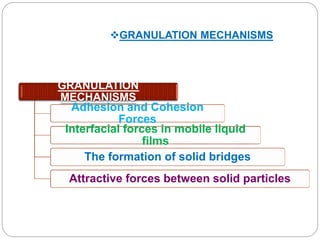

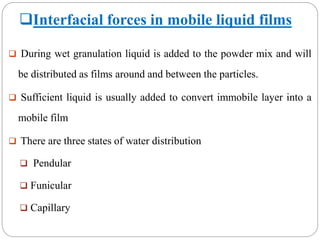

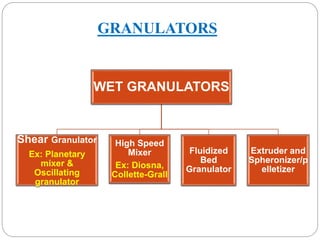

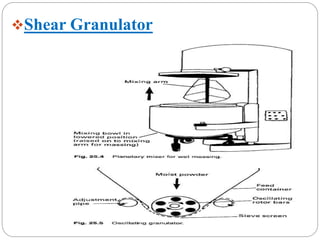

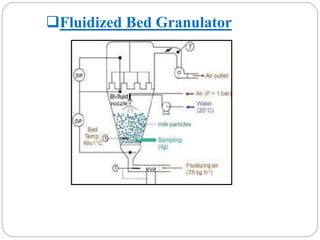

The document discusses different granulation techniques used in pharmaceutical manufacturing including dry and wet granulation. It describes processes like compression granulation, roller compaction, high shear mixing and fluidized bed granulation. The key purposes of granulation are to improve flow properties, compaction characteristics and prevent segregation of powder constituents.