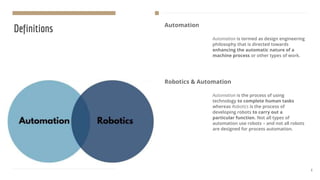

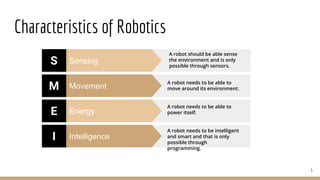

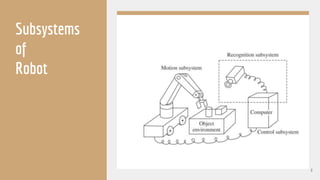

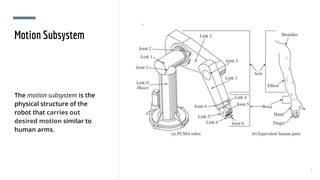

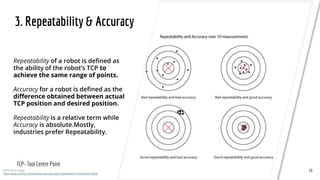

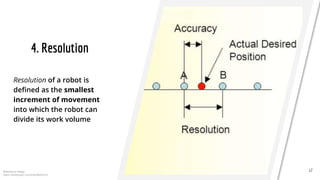

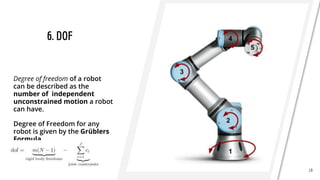

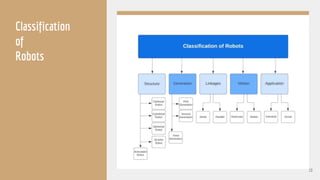

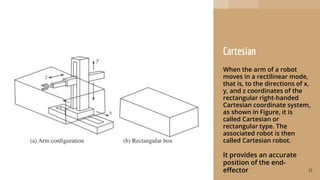

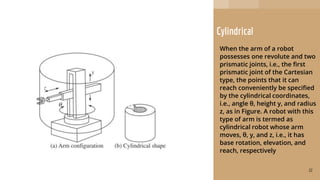

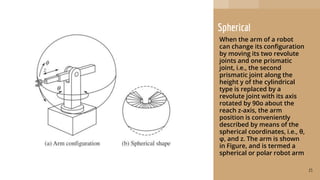

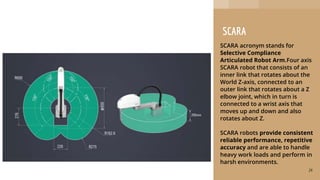

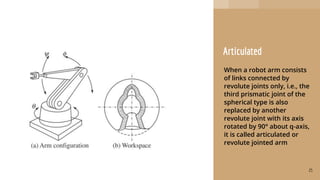

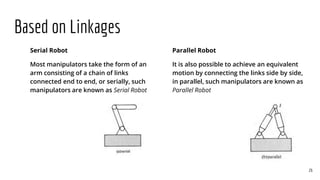

This document serves as an introduction to robotics and automation, defining key concepts such as robots, robotics, and automation while detailing their applications in various industries such as manufacturing and healthcare. It outlines critical characteristics of robots, the principles of robotics according to Asimov's laws, and includes descriptions of different robot classifications and their functions. Additionally, it highlights the significance of robotics for performing dangerous, repetitive, and precision tasks.