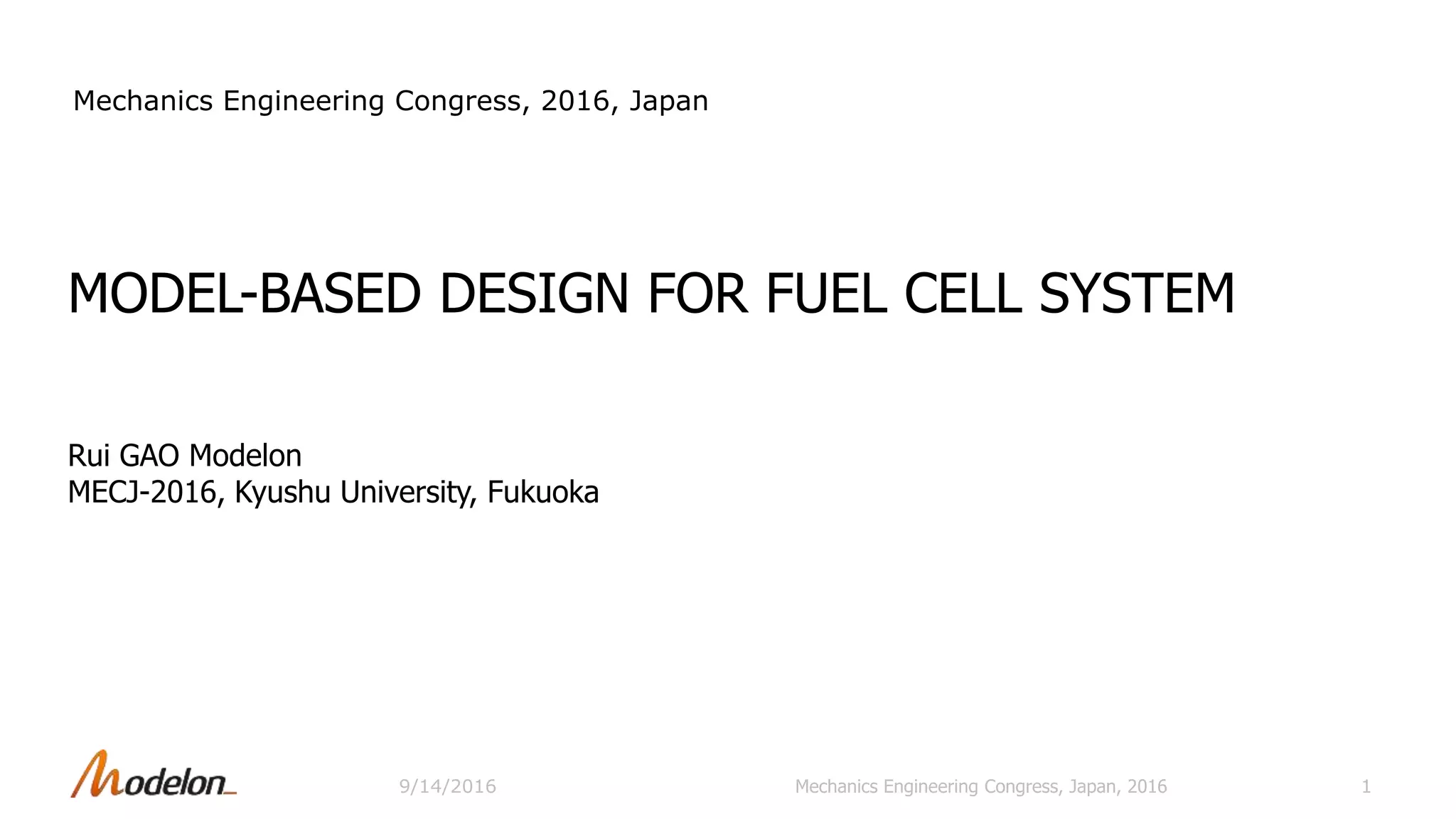

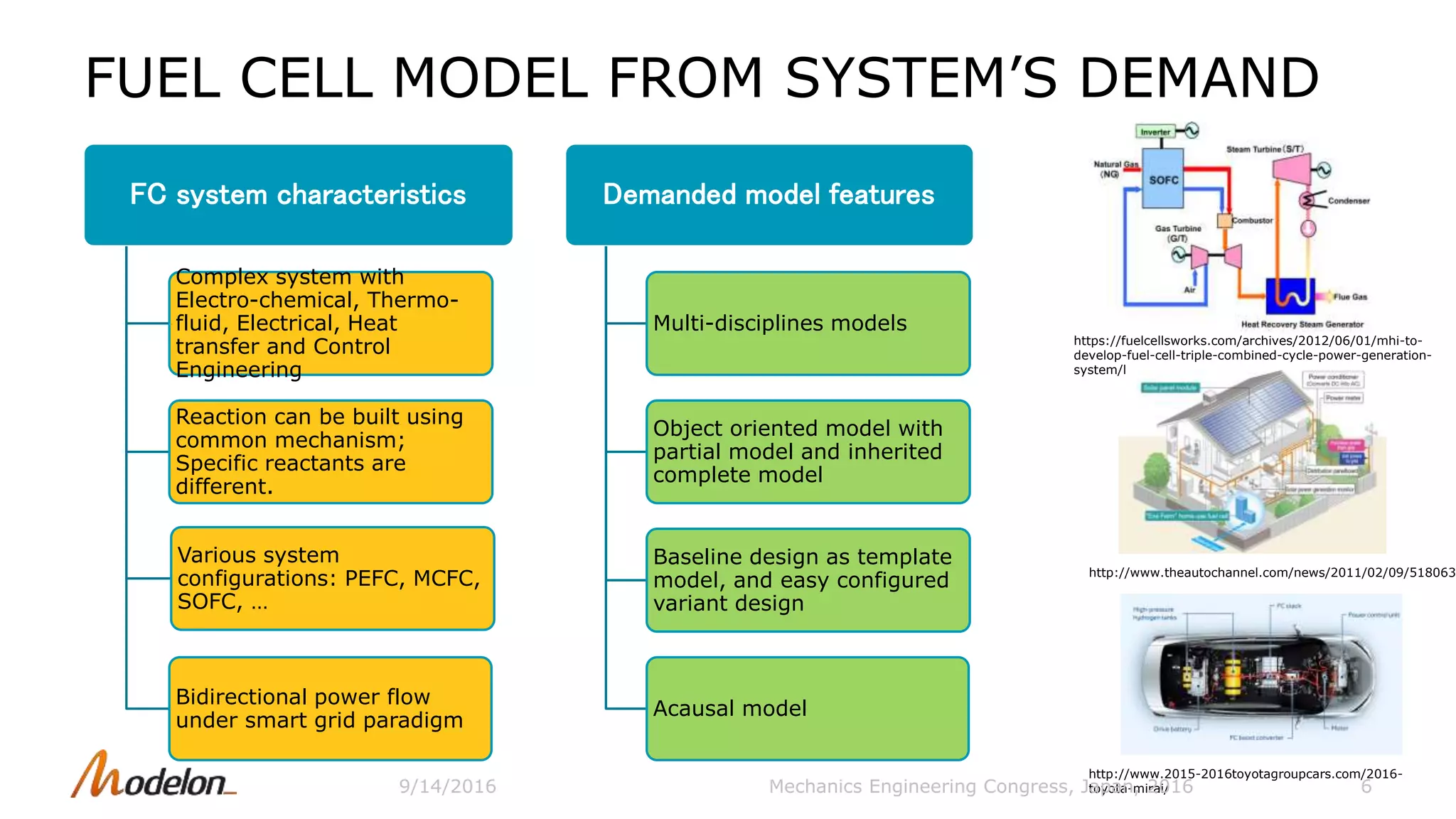

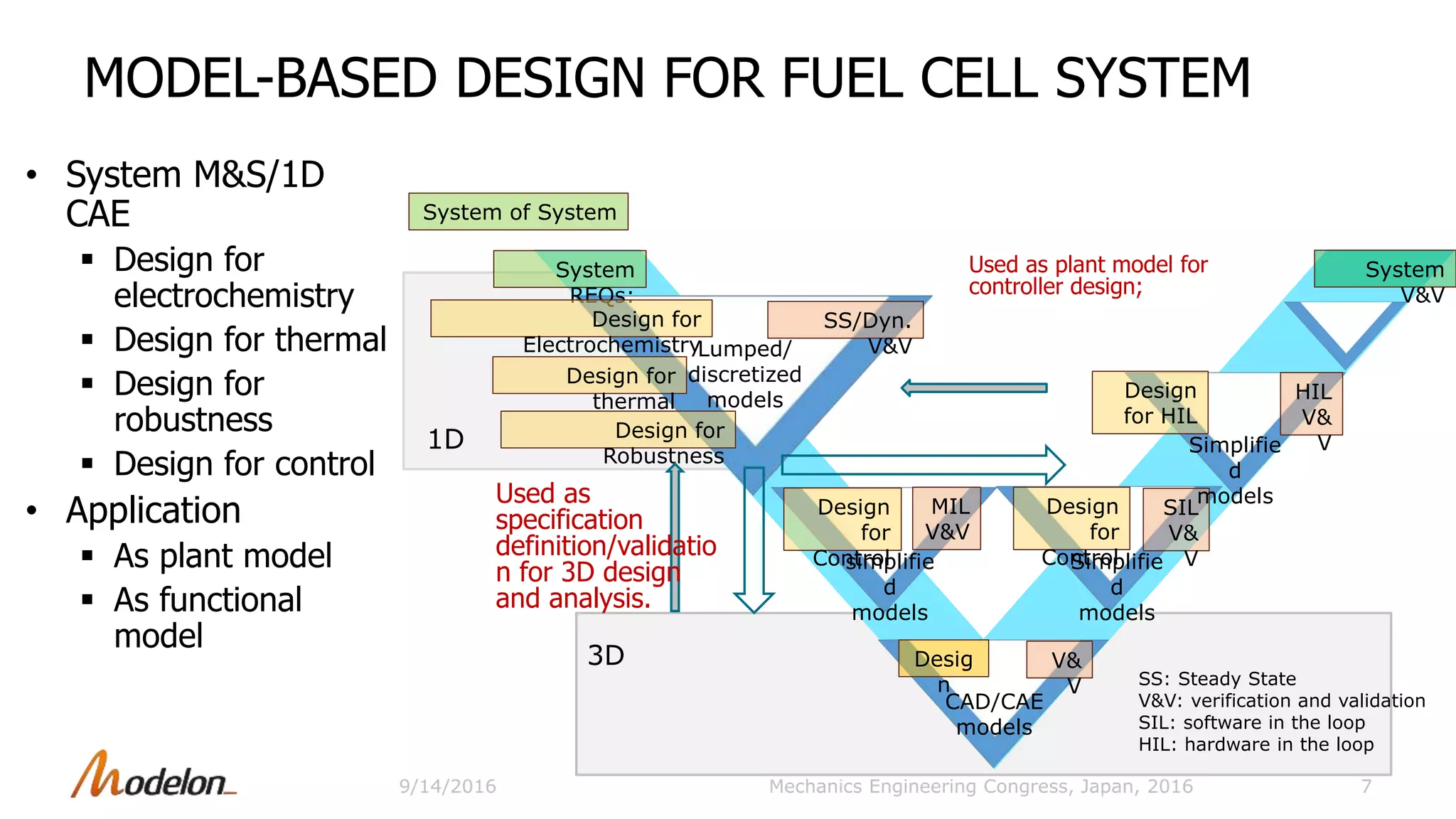

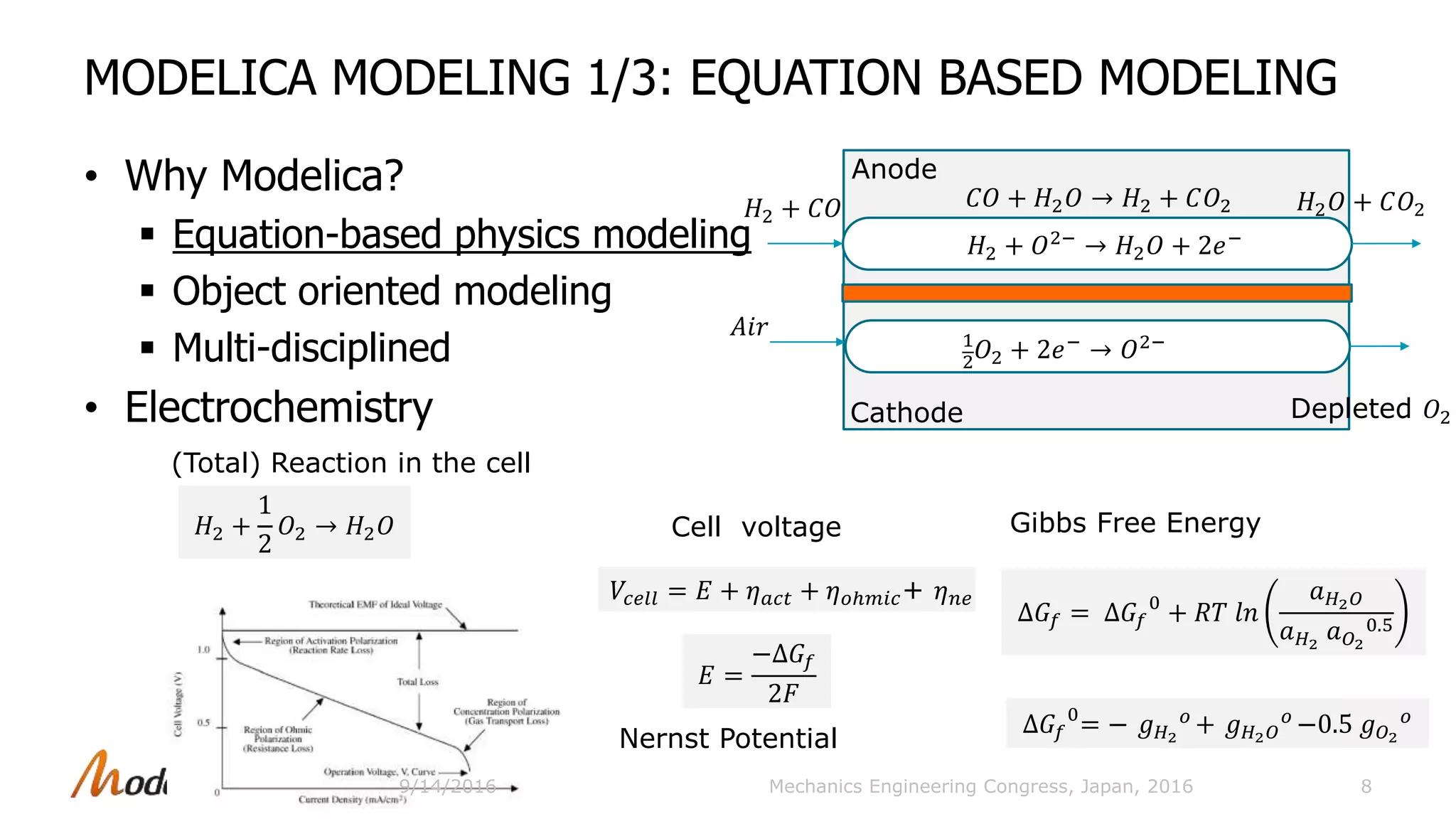

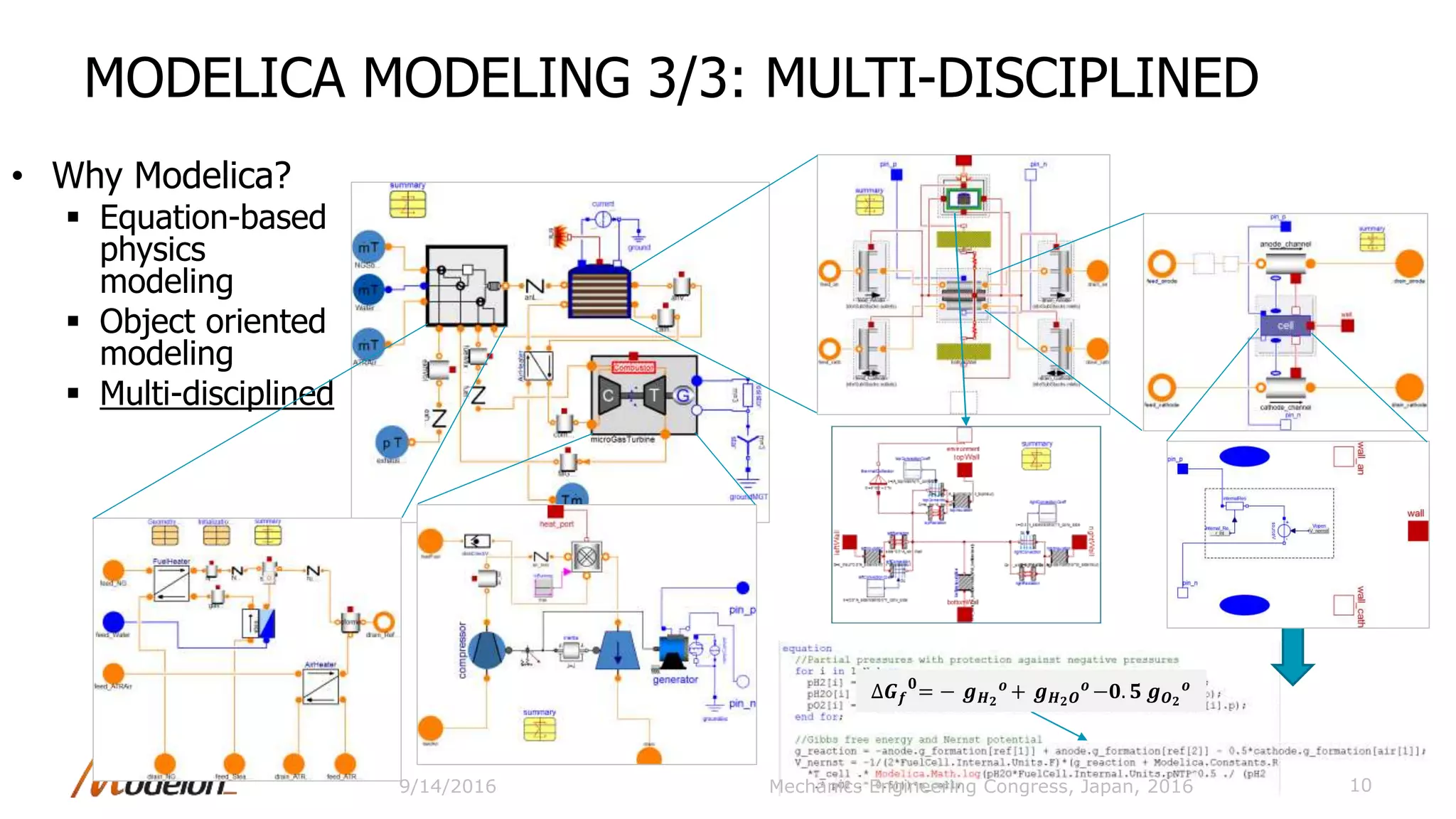

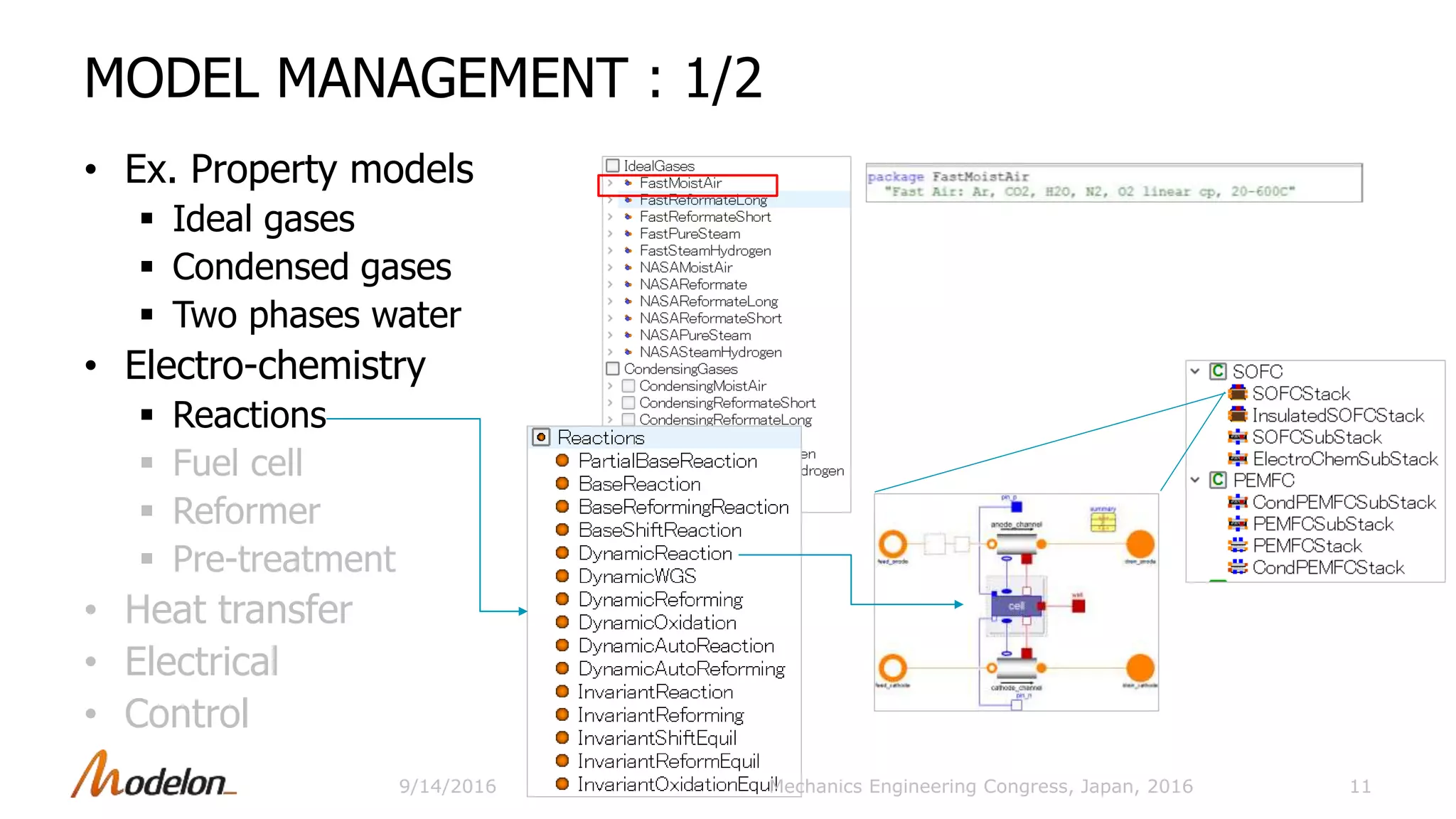

Rui Gao presented on model-based design for fuel cell systems using Modelica. The presentation discussed modeling a hybrid SOFC system from a systems perspective using equation-based and object-oriented Modelica models that integrate multi-disciplinary physics. Subsystem tests were conducted on models of the preprocessor and micro gas turbine. Simulation results showed mass balance, fuel cell voltage-current characteristics, thermal losses, and AC power output. Model-based design was identified as a promising approach for smart grid system development to enable bidirectional power flow.

![MODELICA MODELING 2/3: OBJECT ORIENTED MODELING

• Why Modelica?

Equation-based physics modeling

Object oriented modeling

Multi-disciplined

• Membrane example

connector

Interfaces to electrical, substance,

heat

9

∆𝑮 𝒇

𝟎

= − 𝒈 𝑯 𝟐

𝒐

+ 𝒈 𝑯 𝟐 𝑶

𝒐

−𝟎. 𝟓 𝒈 𝑶 𝟐

𝒐

connector MassPort

Medium medium;

Pressure p;

flow MassFlowRate m_flow;

SpecificEnthalpy h;

flow EnthalphFlowRate

H_flow;

MassFraction X[n.Xi];

flow MassFlowRate

mX_flow[nXi];

end MassPort;

Mechanics Engineering Congress, Japan, 20169/14/2016](https://image.slidesharecdn.com/modelonjsme-2016-mbdforfuelcellsystems-161104073731/75/Modelon-JSME-2016-Model-Based-Design-for-Fuel-Cell-Systems-9-2048.jpg)

![SUB-SYSTEM TESTS

• Sub-system

Preprocessor

Micro gas turbine

13Mechanics Engineering Congress, Japan, 2016

microGasTurbine

GC T

Combustor

feedFuel

mT

.

drainAir

pT

feedAir

mT

.

ground

combustorcombustor

isBurning

true

inertia

J=J

air_loss

summary

generator

groundExc

idealCheckValve

drain

heat_port

feedFuel

feedAir

pin_p

pin_n

0 100 200 300 400 500 600 700 800 900 1000

0.0

0.5

1.0

1.5

2.0

2.5

feedFuel.fluidPort.p feedAir.fluidPort.p

0 100 200 300 400 500 600 700 800 900 1000

-0.025

-0.020

-0.015

-0.010

-0.005

0.000

0.005

feedFuel.m_flow feedAir.fluidPort.m_flow

0 100 200 300 400 500 600 700 800 900 1000

-200

-150

-100

-50

0

50

100

150

200

250

resistor.i[1] resistor.i[2] resistor.i[3]

0 200 400 600 800 1000

-4000

-2000

0

microGasTurbine.generator.flange.tau

Test model

Test model

flowSource_Water

mT

.

flowSource_NG

mT

.

flowSource_AirATR

mT

.

Boundary_hotgas

p T

flowSource_Hotgas

mT

.

flowSource_ATRHeat

mT

.

Boundary_ATRHeat

pT

Boundary_Reformate

pT

turbulentLoss

preprocessor

0.0H2

CH4 0.0

CO 0.0

CO2 0.0

H2O 0.0

Mole %

N2 0.0

O2 0.0

0.0 0.0

0.0 0.0

p(bar)h(kJ/kg)

T(degC)(g/s)

reformer

steamMix_TZ

AirHeater

Geometry_Record Initialization_Record summary

FuelHeater

fuelLoss

gasMix

NGMix

NGLoss

drain_Reformate

feed_NG

drain_NGHeat feed_SteamHeat feed_ATRHeatdrain_ATRHeat

feed_Water

feed_ATRAir

9/14/2016](https://image.slidesharecdn.com/modelonjsme-2016-mbdforfuelcellsystems-161104073731/75/Modelon-JSME-2016-Model-Based-Design-for-Fuel-Cell-Systems-13-2048.jpg)

![HYBRID SOFC SYSTEM SIMULATION RESULT

• Analysis

Mass balance

Fuel cell

voltage-current

density relation

Thermal loss

Power-current

density relation

AC power

14Mechanics Engineering Congress, Japan, 2016

0 400 800 1200 1600 2000 2400 2800 3200 3600 4000

0.0E0

4.0E-5

8.0E-5

1.2E-4

1.6E-4

2.0E-4

checkMassBalanceSystem.mH_in

checkMassBalanceSystem.mH_out

checkMassBalanceSystem.mC_in

checkMassBalanceSystem.mC_out

Voltage [V] Power [W]

Stack

flowCathode

mT

.

ground

current

stack

summary

WaterSource

mT

.

NGSource

mT

.

ATRAirSource

mT

.

exhaustSink

p T

preprocessor

anLoss anVolume

cathVolume

microGasTurbine

GC T

Combustor

MGT_volOut

groundMGT

compMix

checkMassBalanceSystem

44.8 4478

0 1000 2000 3000 4000

0

50

100

150

current.i

0 1000 2000 3000 4000

35

40

45

50

55

current.v

500 1000 1500 2000 2500

40

42

44

46

48

50

stack.subStack[1].summary.j_external [A/m2]

current.v

0 400 800 1200 1600 2000 2400 2800 3200 3600 4000

0E0

1E5

2E5

3E5

4E5

resistor.resistor[1].LossPower

Mass balance

Fuel cell characteristic

Load current

AC power

0 400 800 1200 1600 2000 2400 2800 3200 3600 4000

750

760

770

780

790

800

810

stack.stackHeatLosses.topWall[1].T

stack.stackHeatLosses.topWall[2].T

stack.stackHeatLosses.topWall[3].T

stack.stackHeatLosses.topWall[4].T

Temperature of the stack top

500 1000 1500 2000 2500

40

42

44

46

48

50

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

stack.subStack[1].summary.j_external [A/m2]

current.v stack.summary.PStkElec*

Voltage, power/current density relatio

9/14/2016](https://image.slidesharecdn.com/modelonjsme-2016-mbdforfuelcellsystems-161104073731/75/Modelon-JSME-2016-Model-Based-Design-for-Fuel-Cell-Systems-14-2048.jpg)