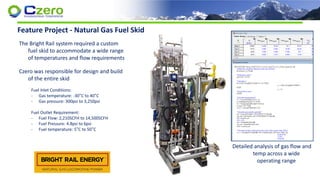

Czero is an engineering services company specializing in mechanical design and prototyping for early stage R&D projects. They have expertise in areas such as engines, hydraulics, and energy systems. Some of their recent projects include designing a natural gas generator system for a locomotive, CO2-based cleaning machines, and a subsea hydraulic pump assembly. Czero takes projects from concept through detailed design, analysis, prototyping, and testing using virtual engineering methods to provide quick iterations to clients.