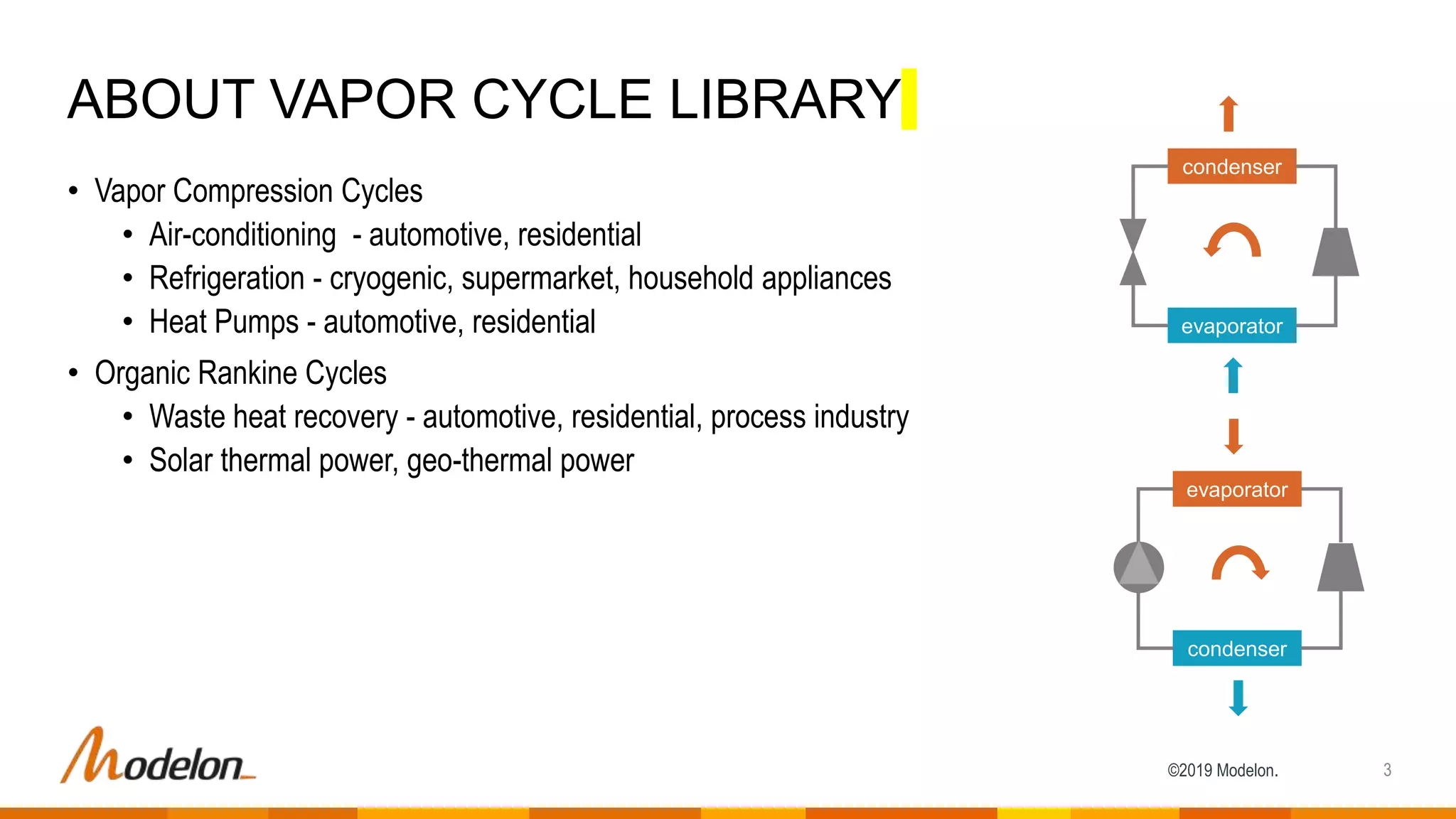

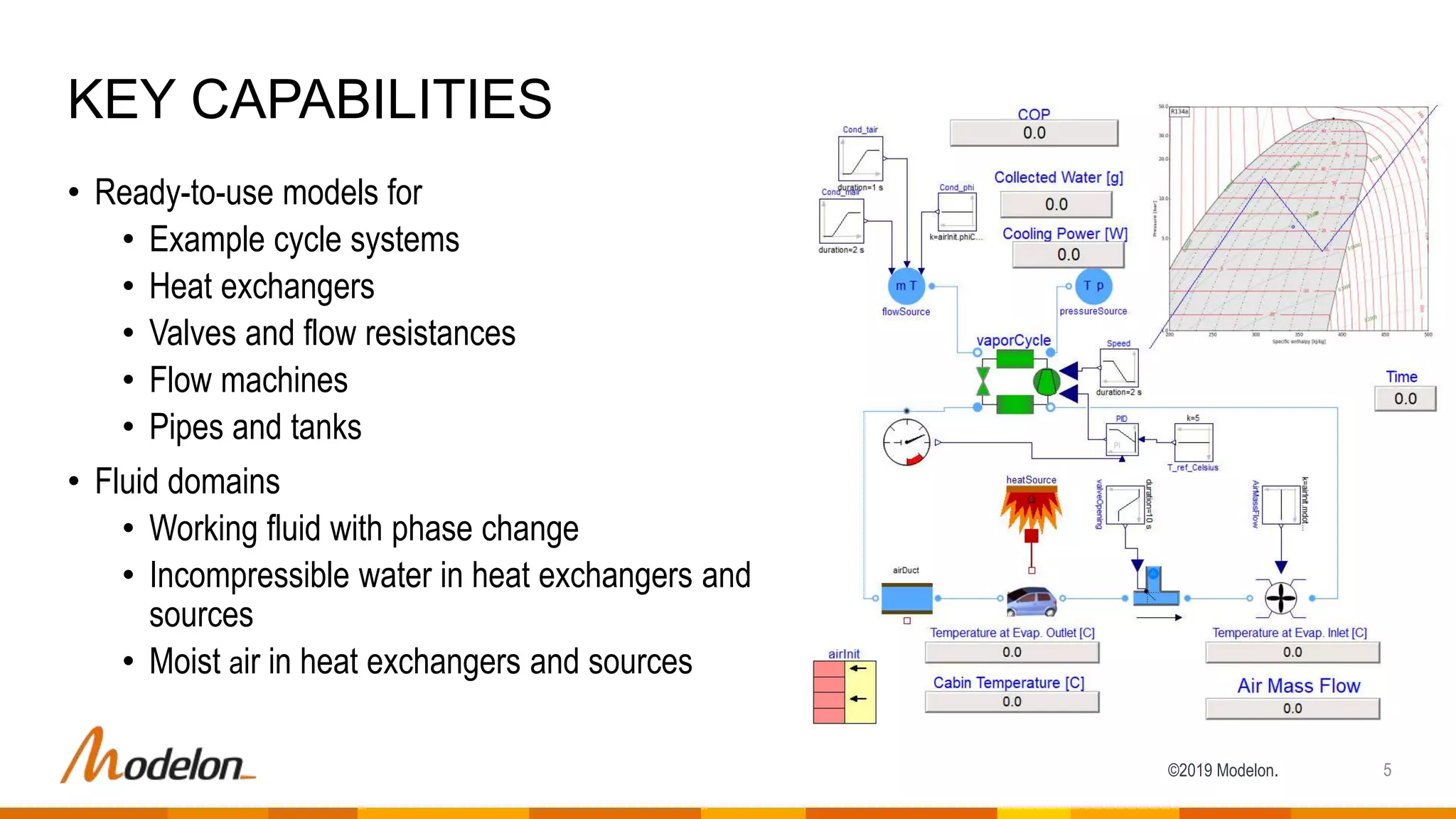

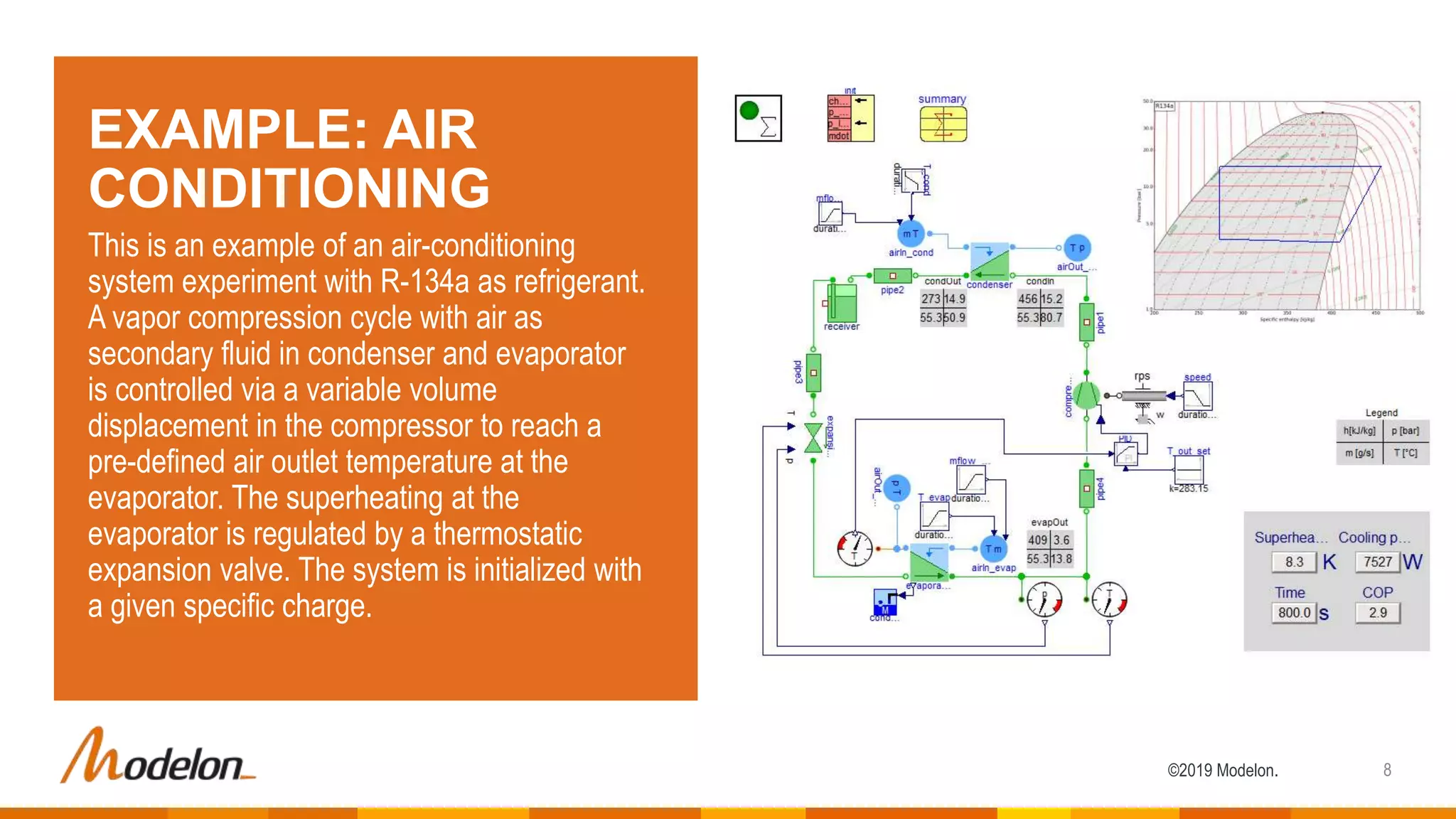

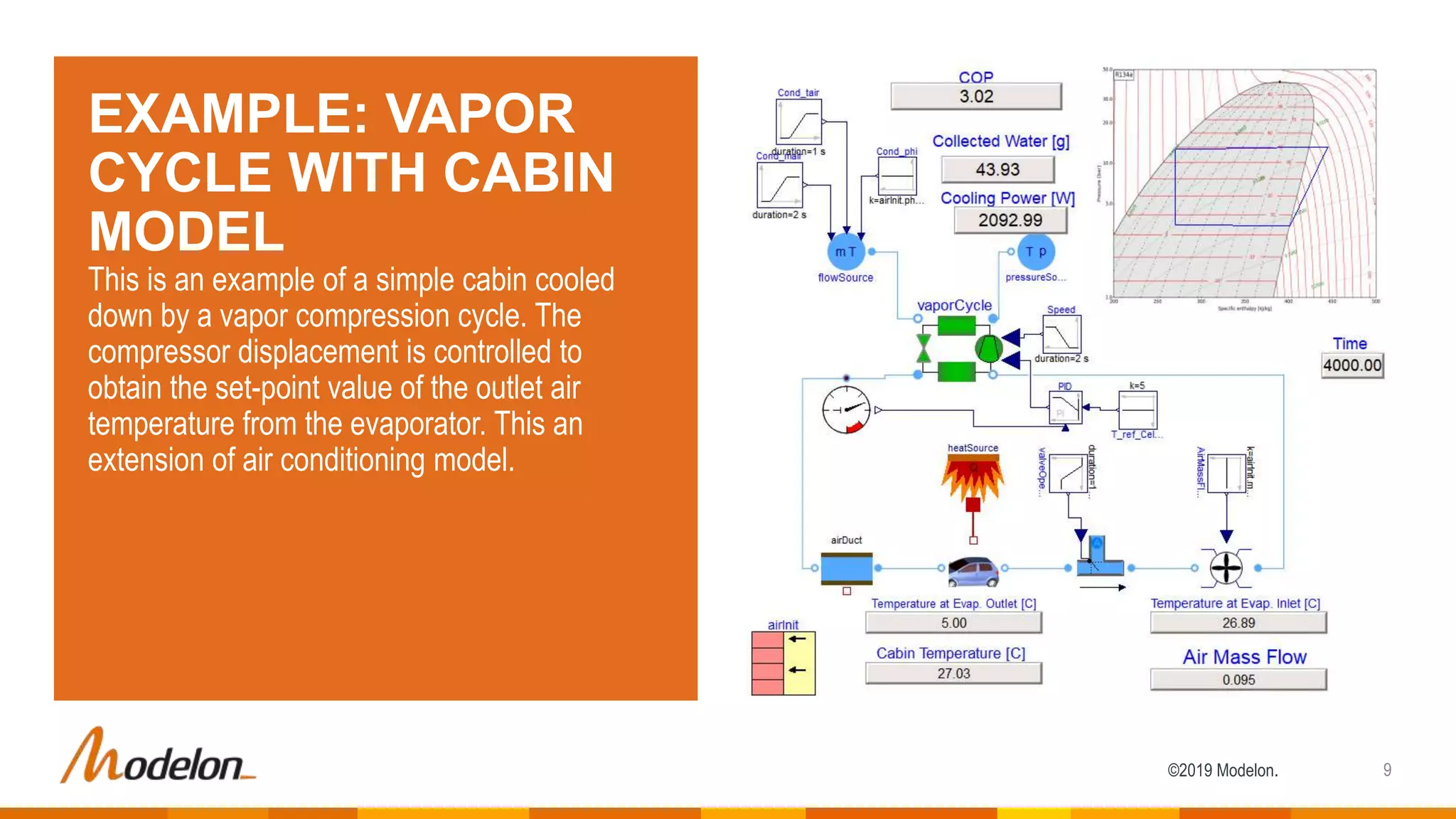

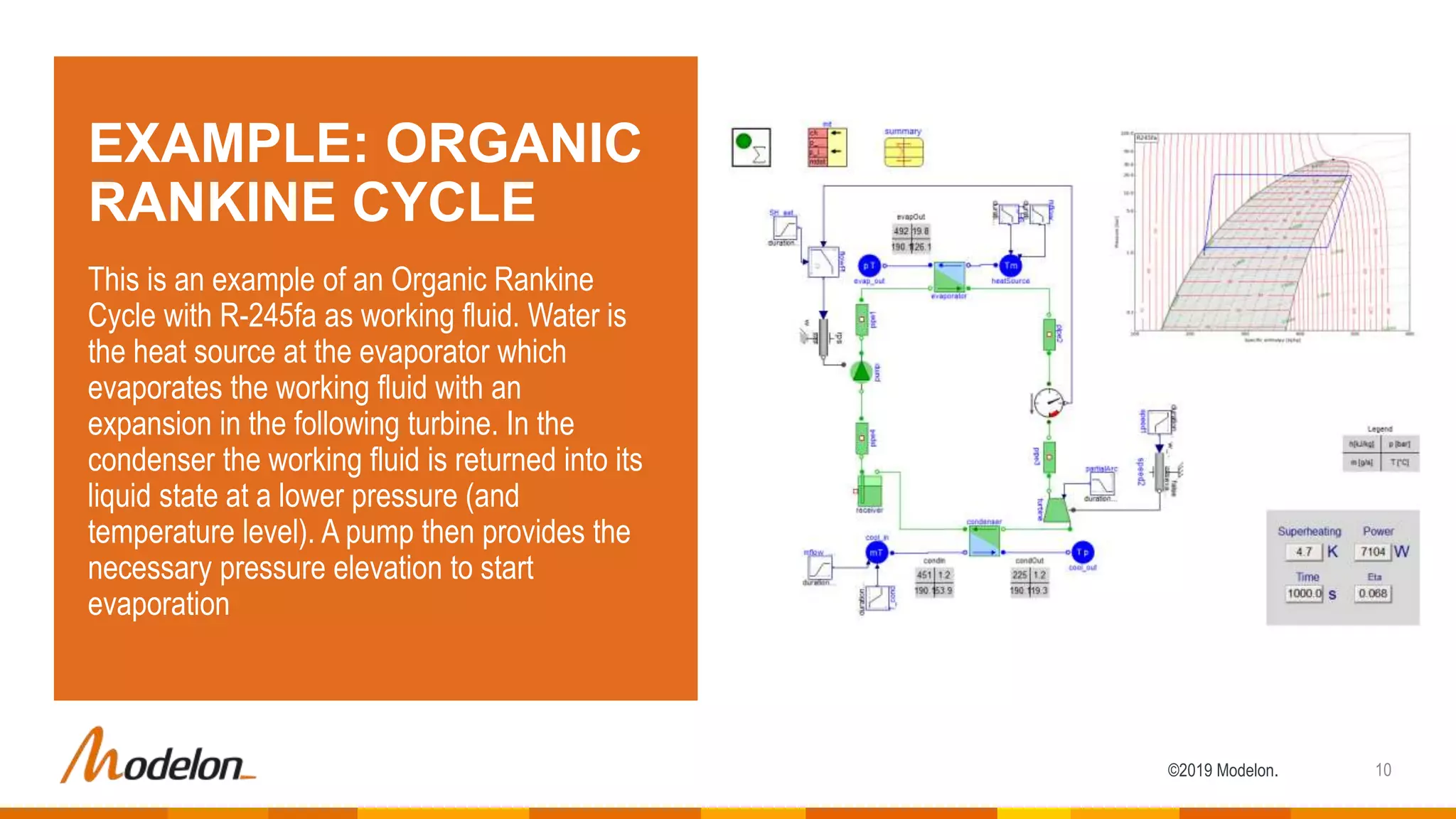

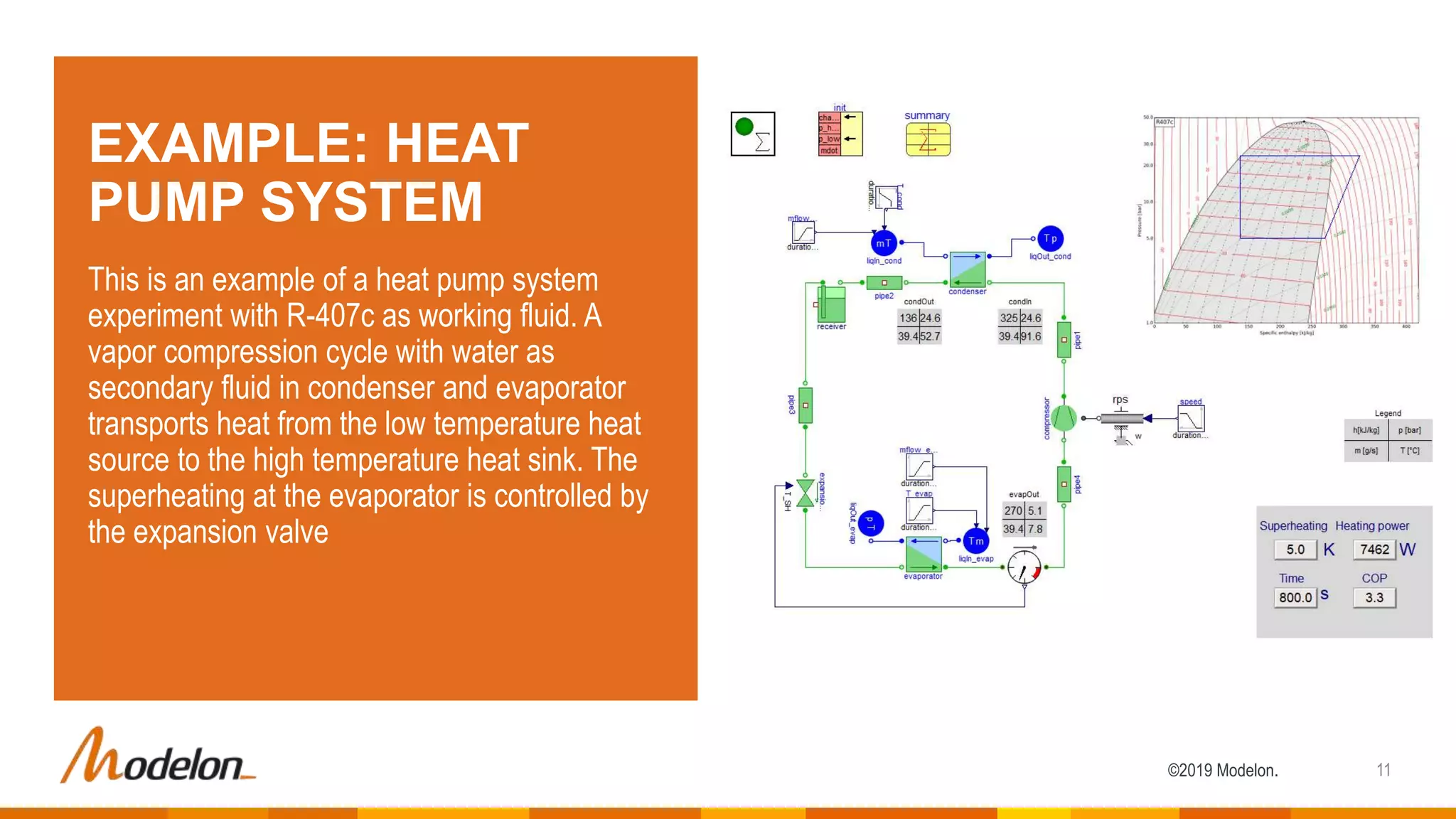

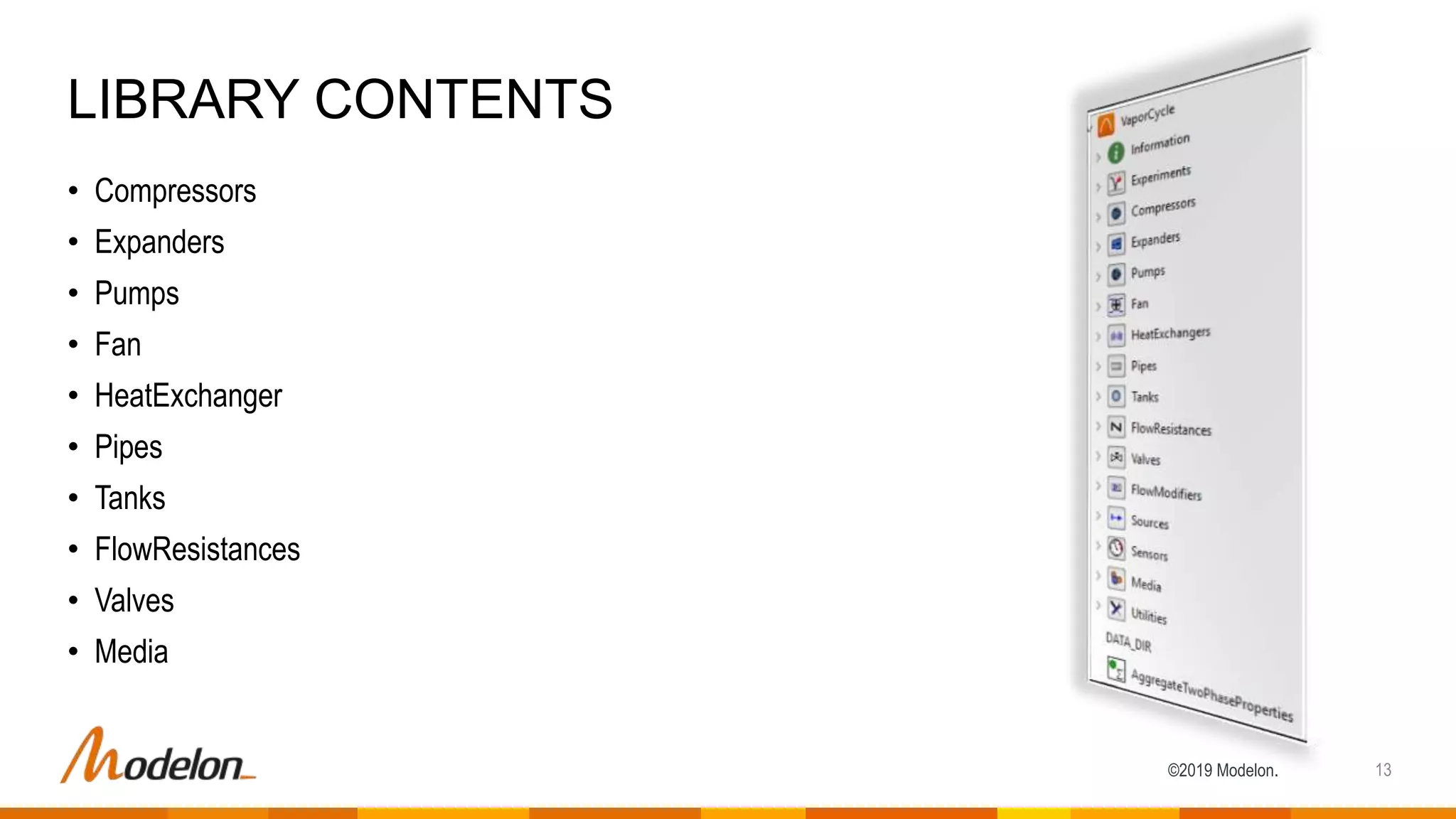

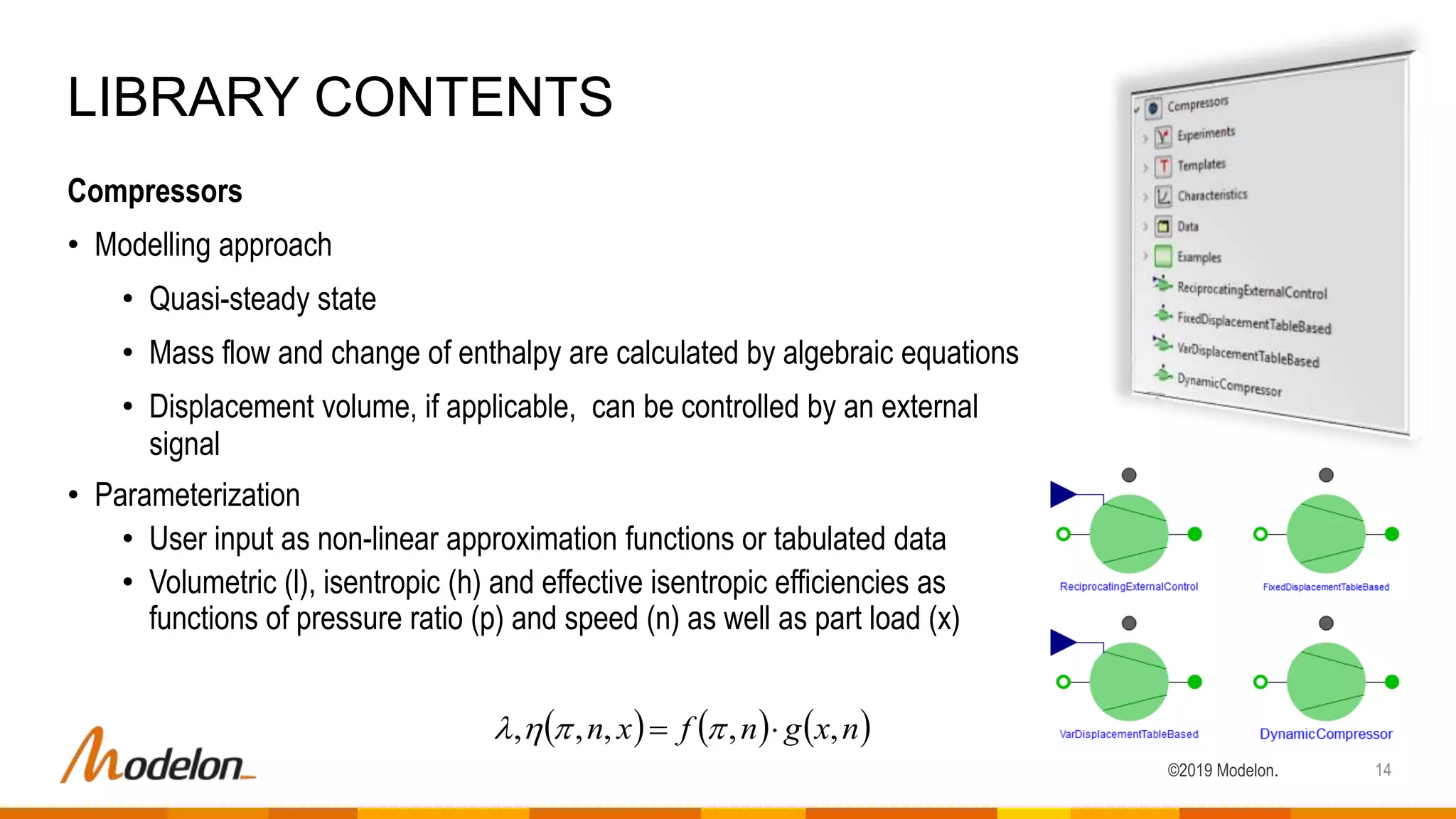

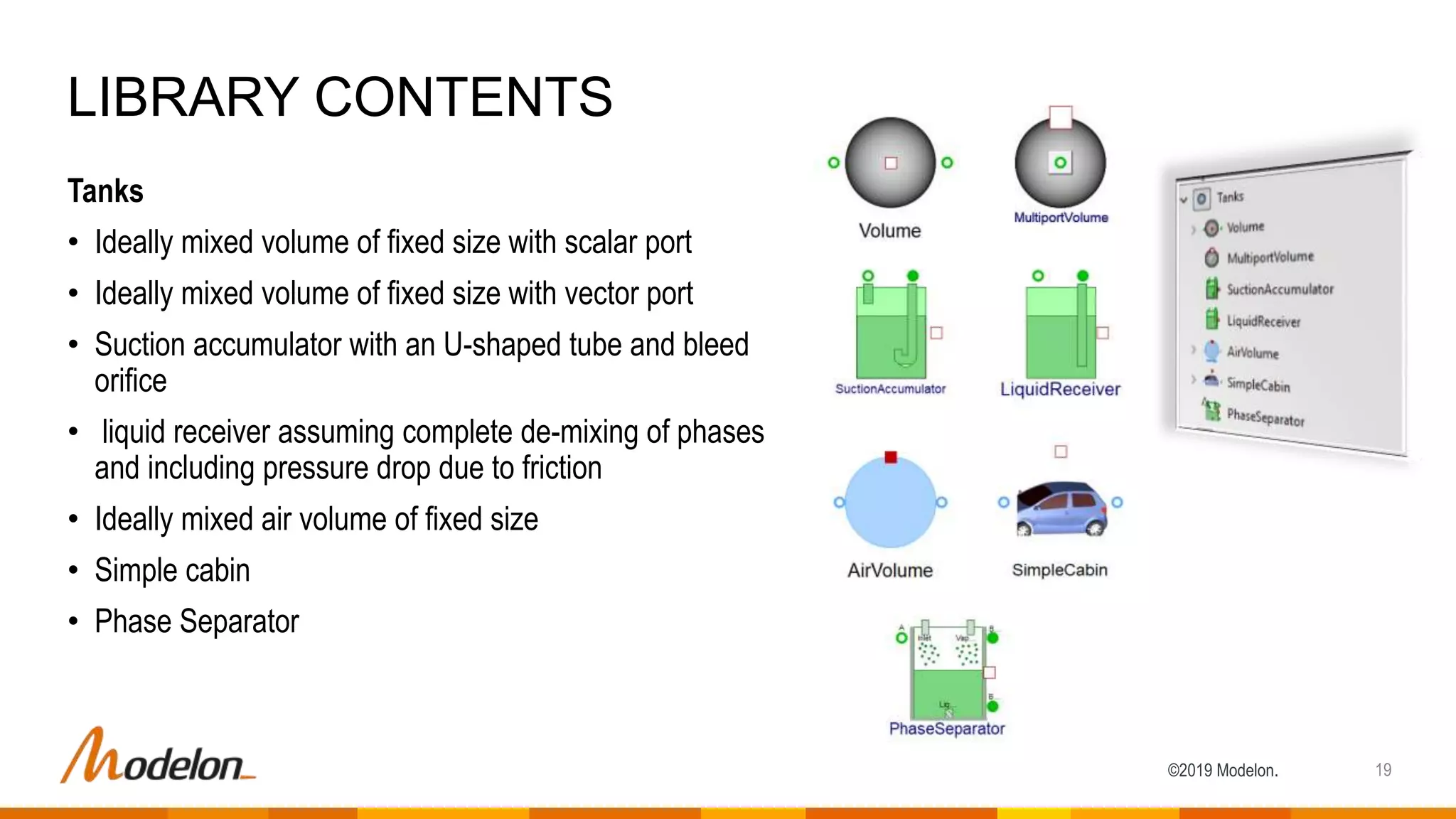

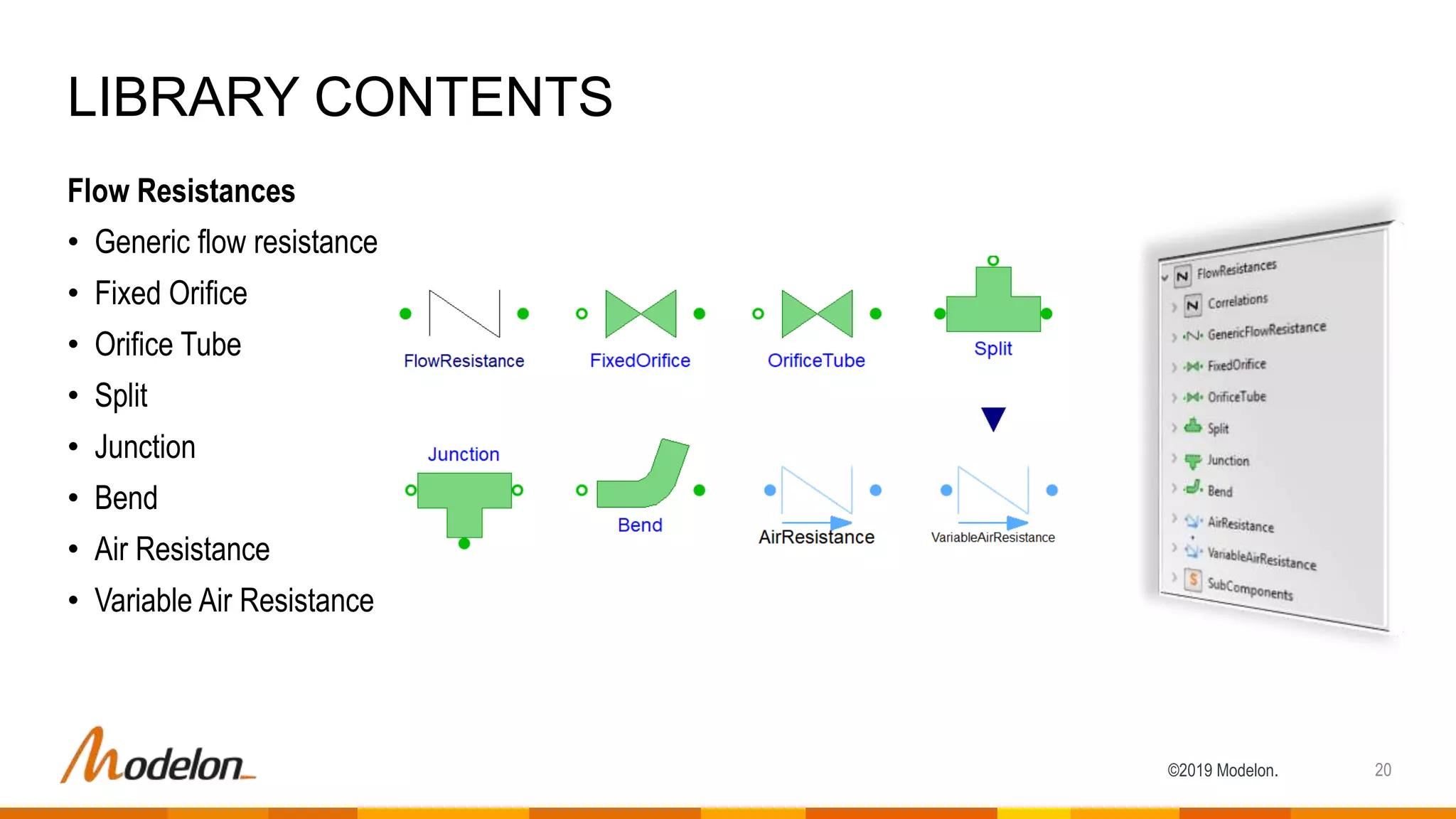

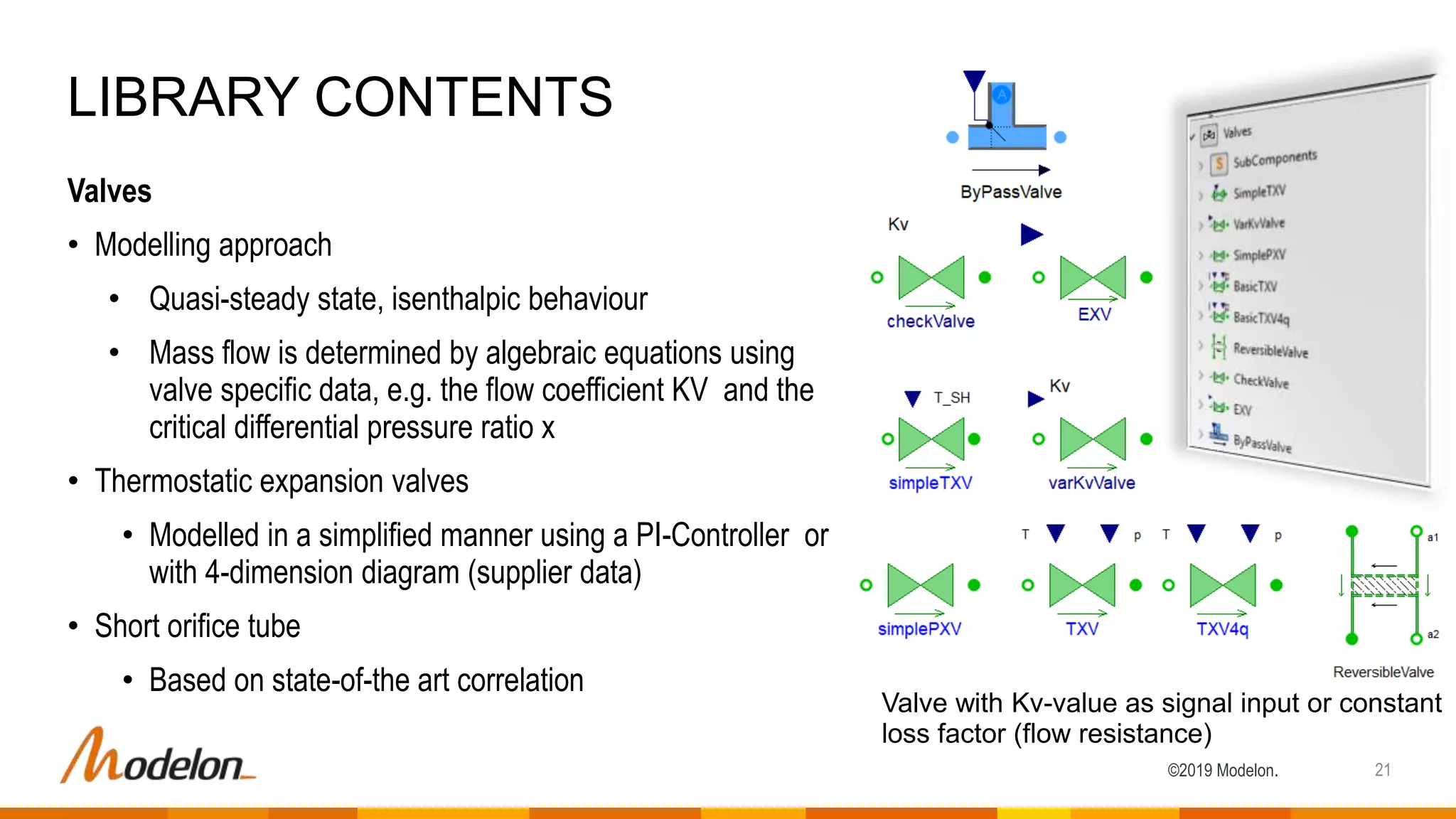

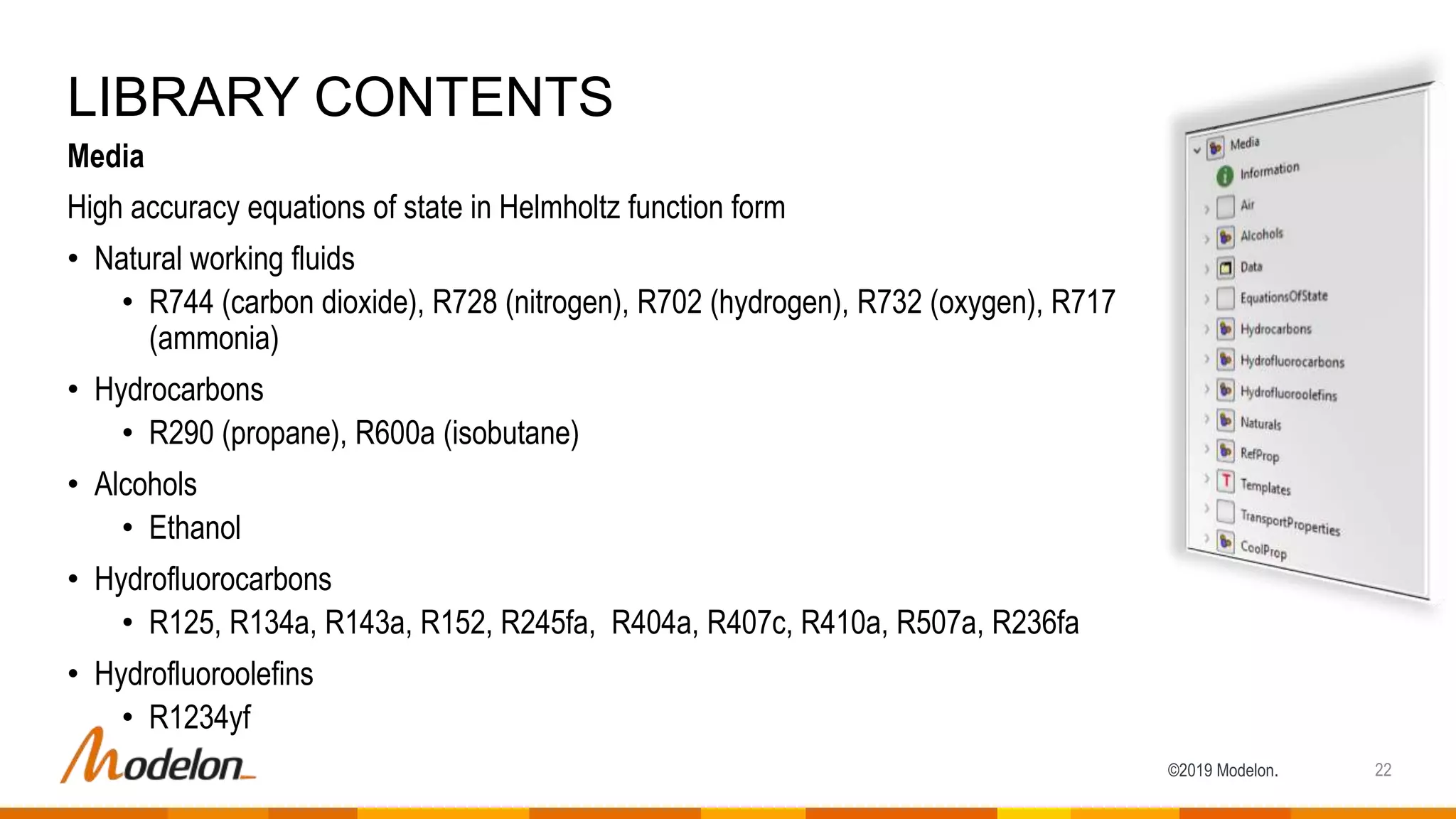

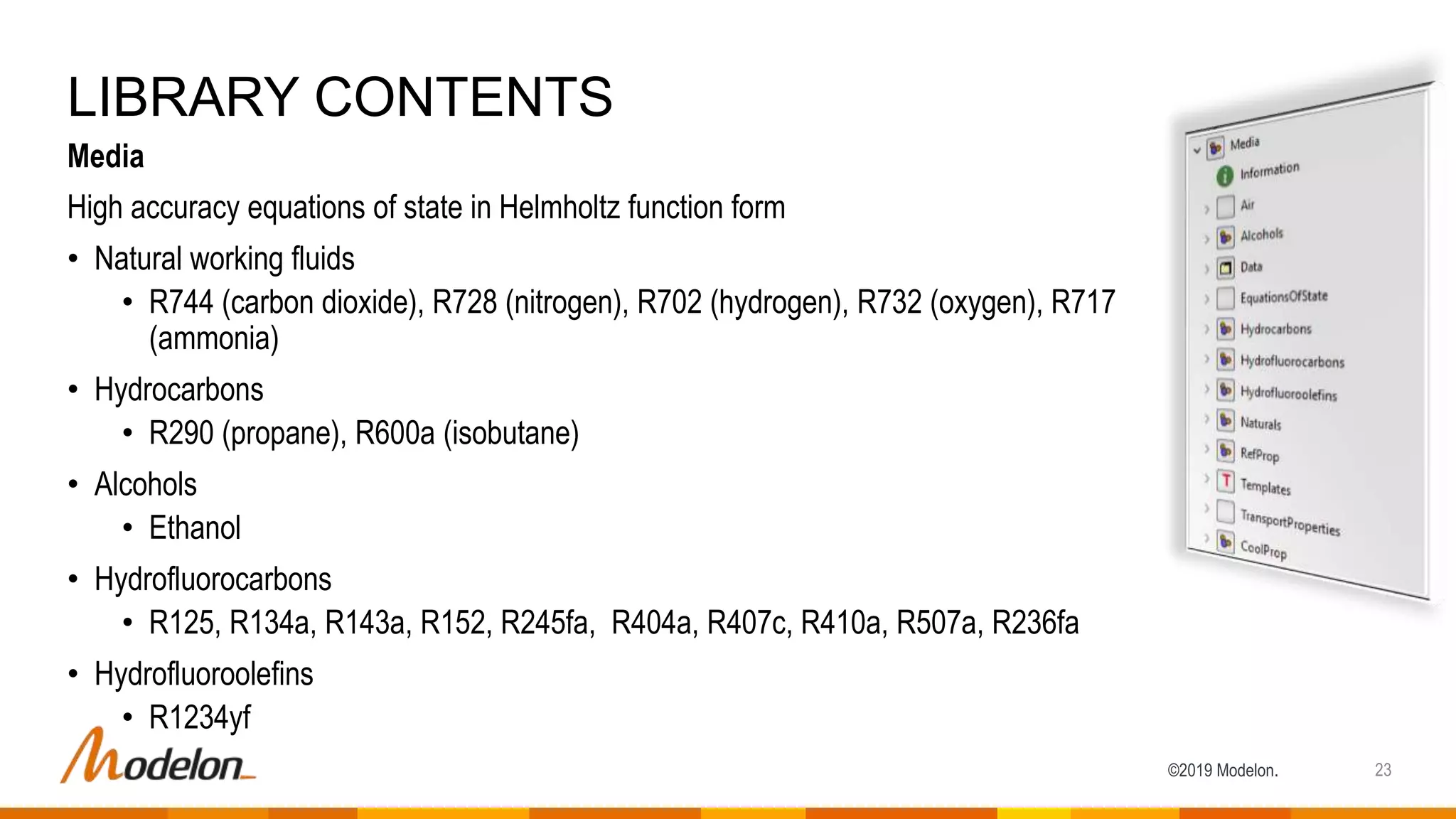

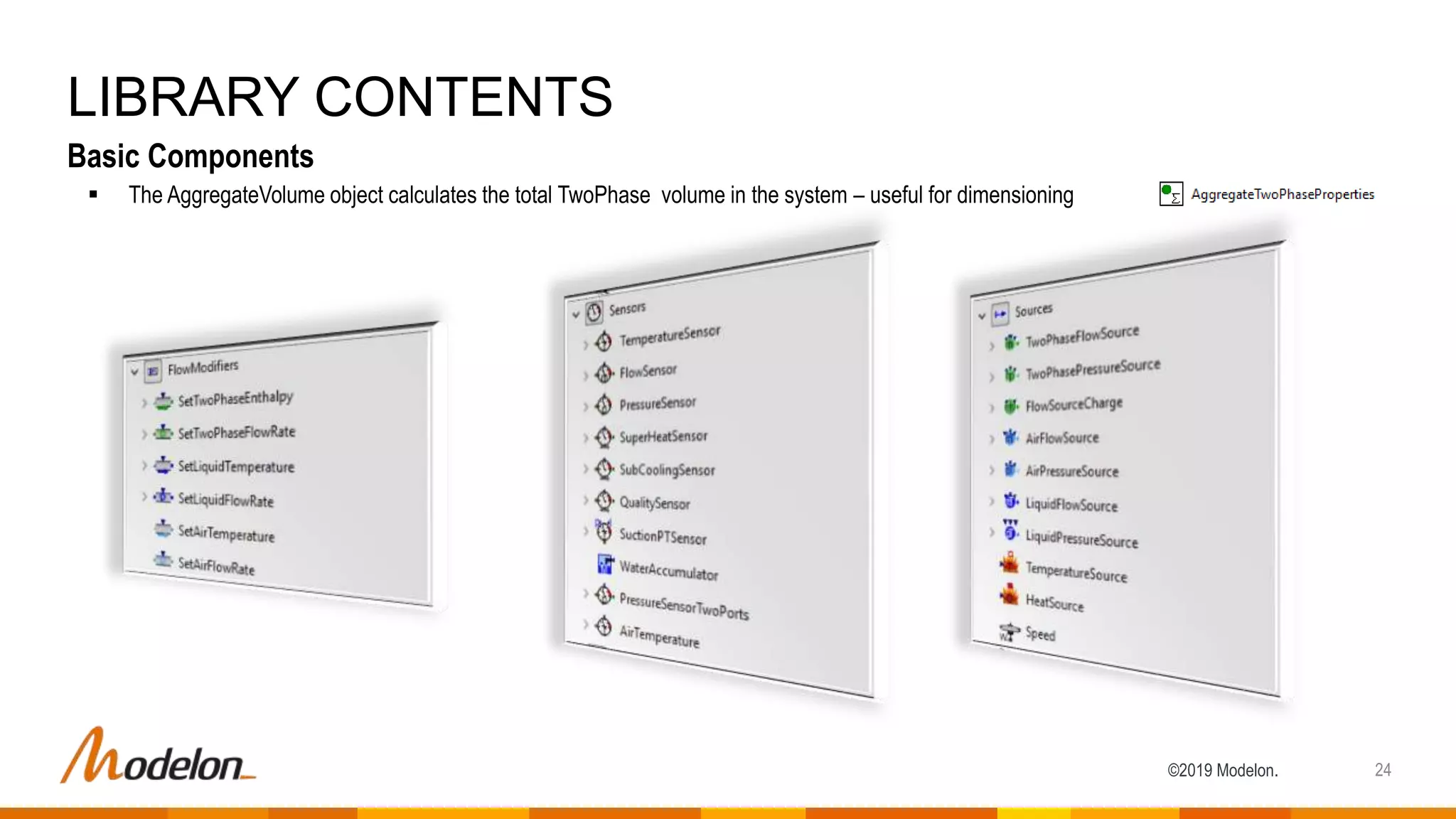

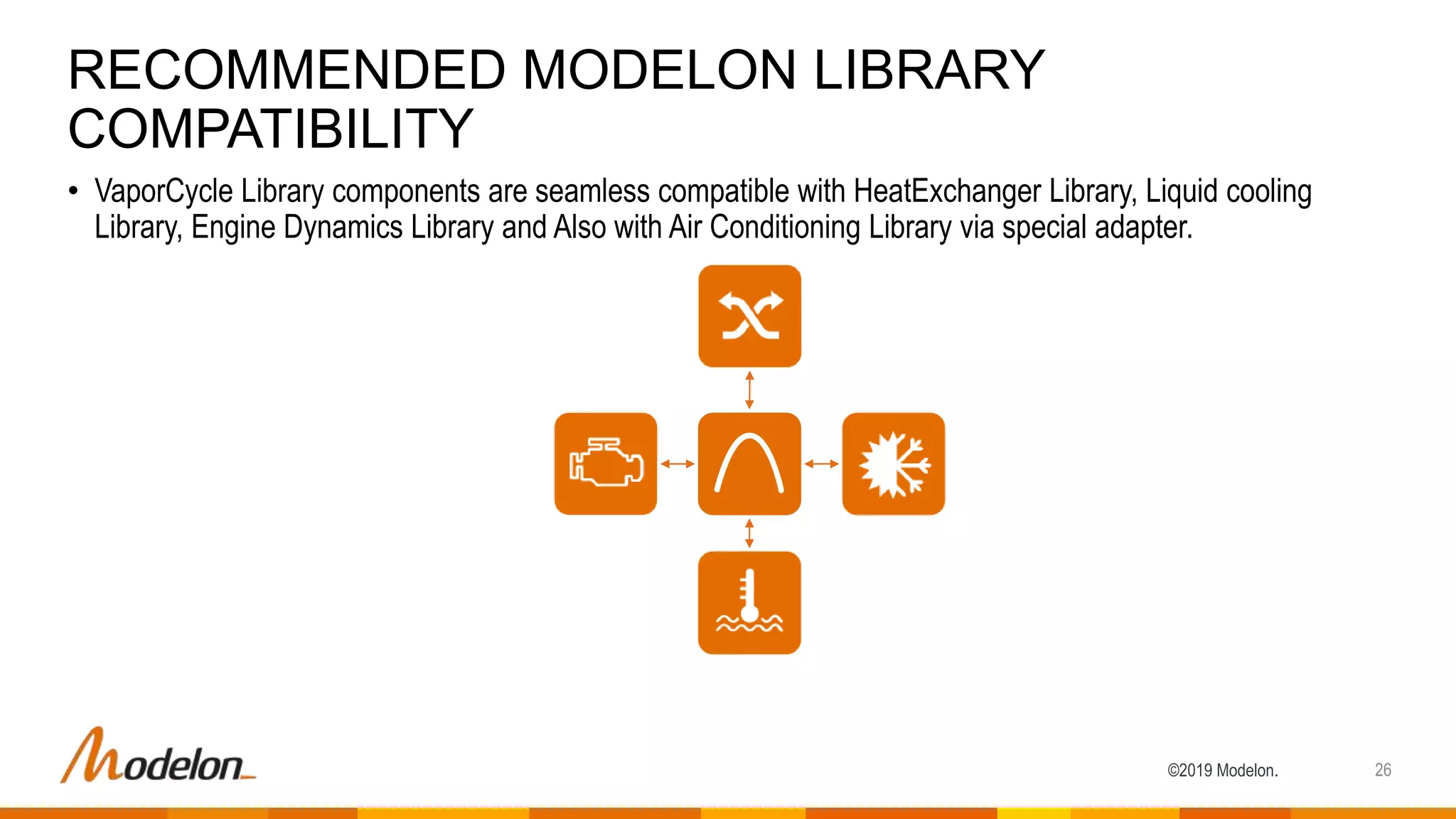

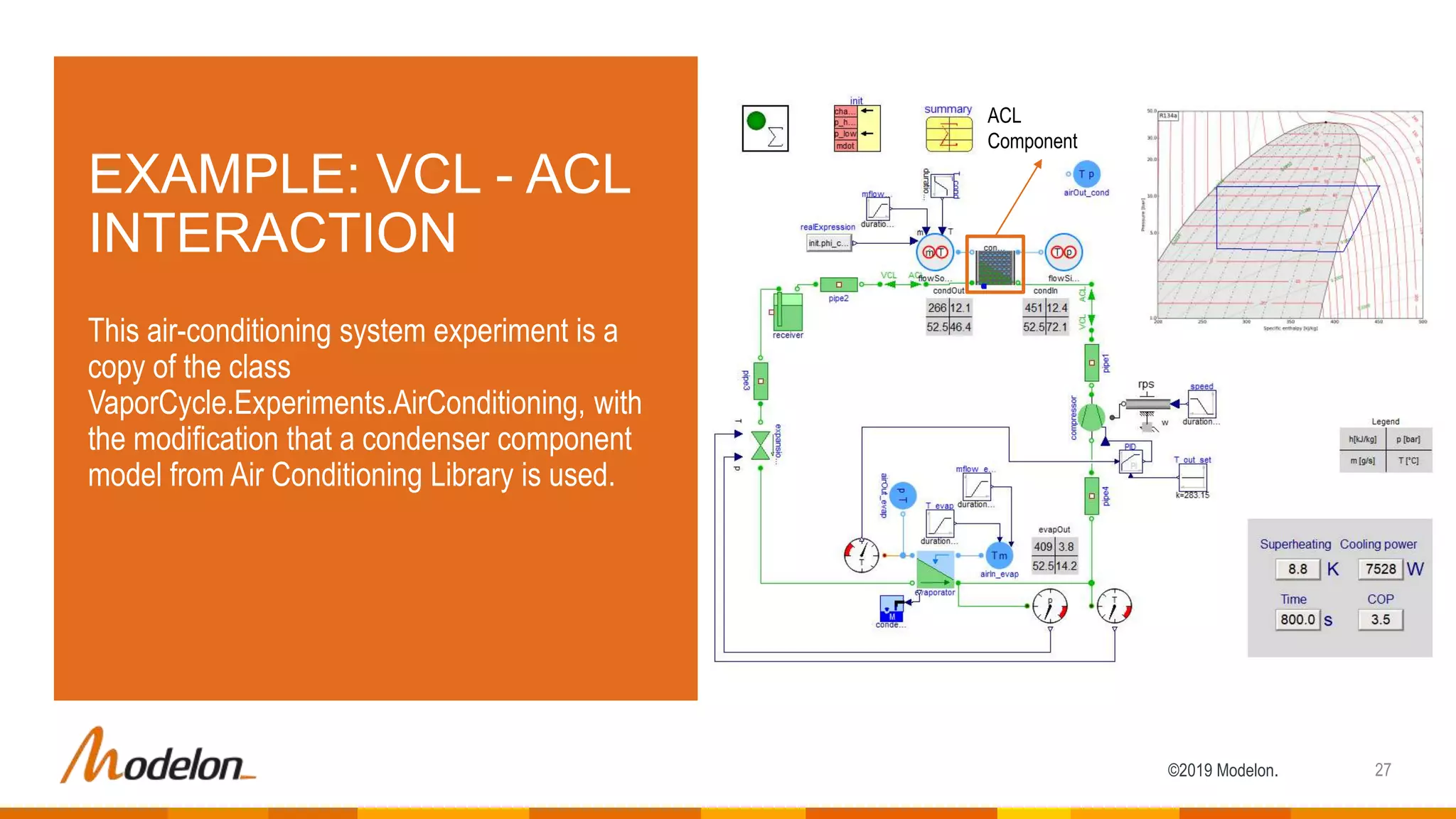

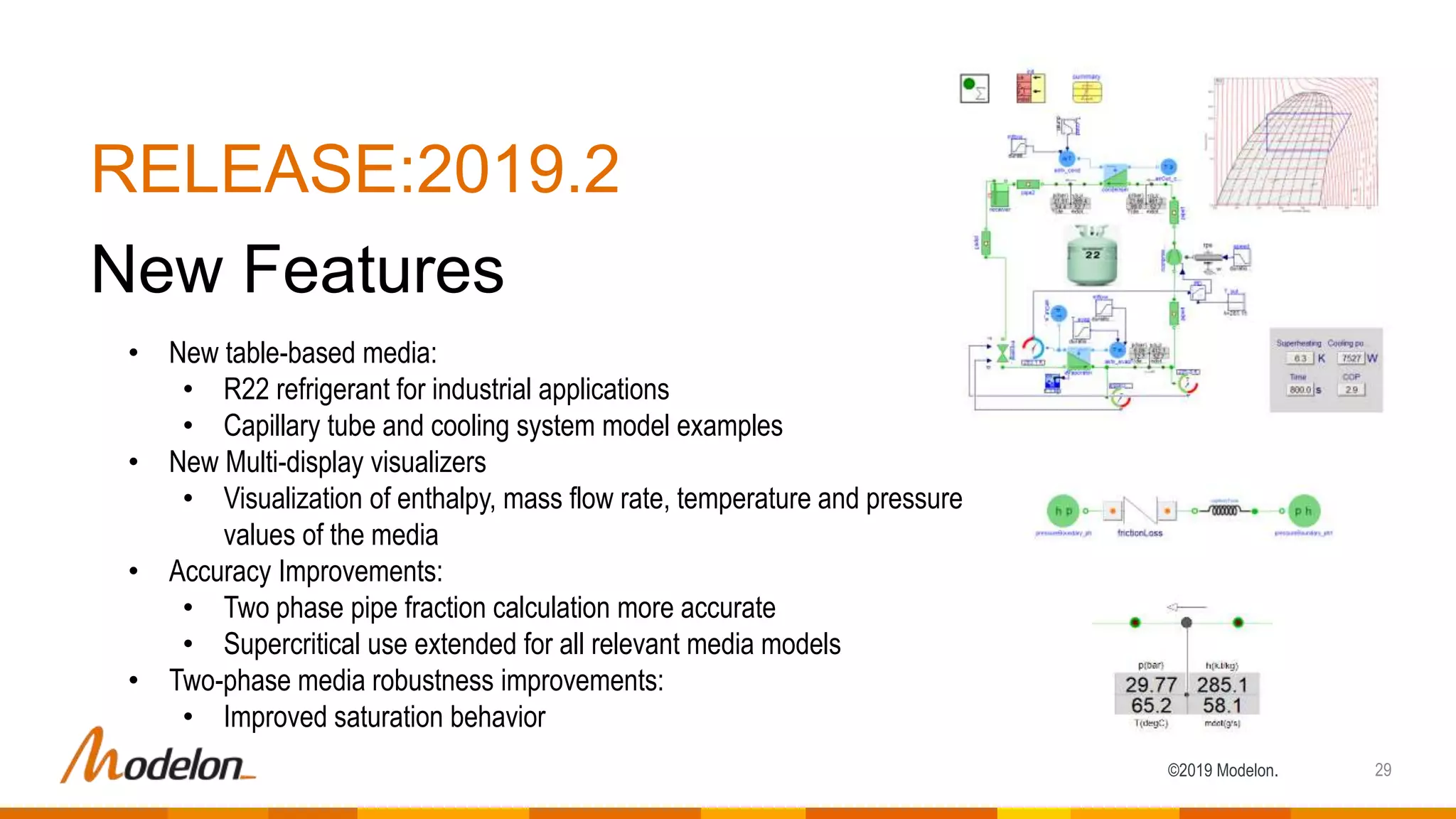

The Vapor Cycle Library provides comprehensive modeling capabilities for vapor compression cycles, including applications in air-conditioning, refrigeration, heat pumps, and organic Rankine cycles. It features ready-to-use models for various components, supports a wide range of working fluids, and allows for flexible system architectures. The latest release (2019.2) includes enhancements such as new refrigerants, improved visualization tools, and greater accuracy in calculations.