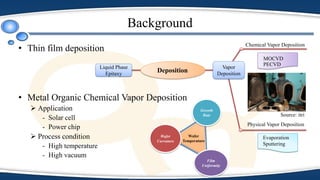

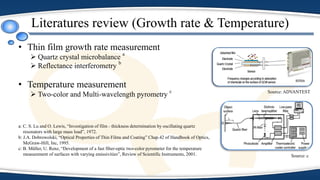

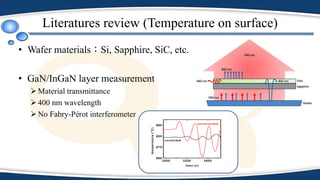

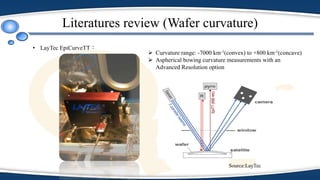

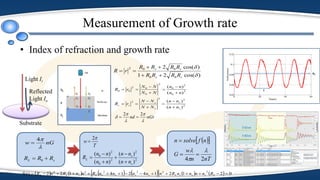

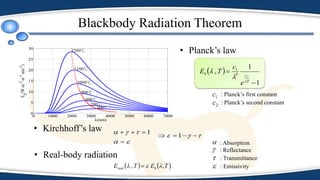

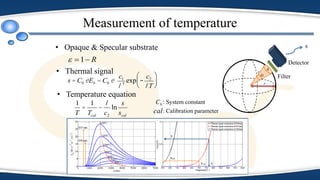

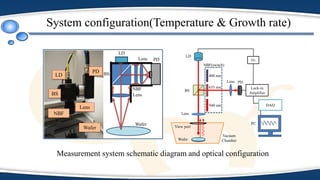

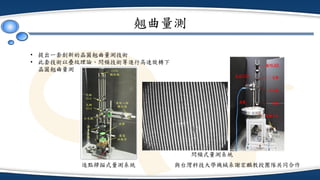

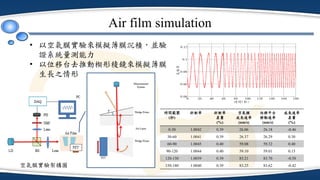

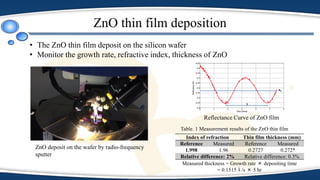

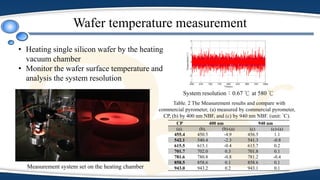

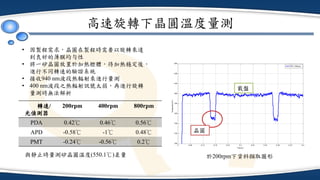

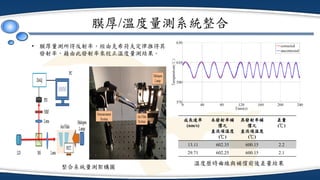

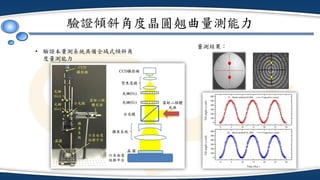

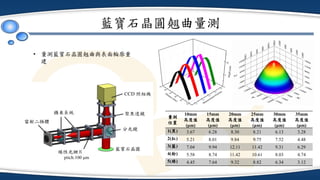

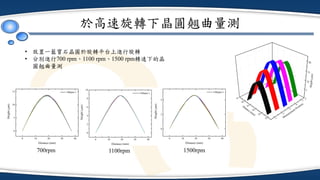

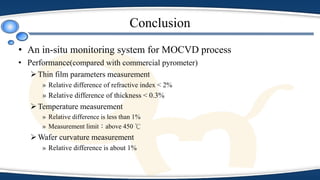

This document summarizes an in-situ monitoring system for MOCVD semiconductor processes. It discusses the principles of measuring growth rate, temperature, and wafer curvature during deposition. Experiments were conducted to validate the system, including simulating thin film deposition with displaced mirrors, depositing and characterizing a ZnO thin film, and measuring the temperature of a heated silicon wafer. The system achieved high accuracy in measurements compared to commercial tools. Future work will focus on improving dynamic measurement capabilities and developing a modular and compatible design.