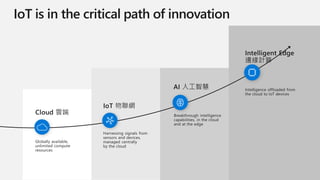

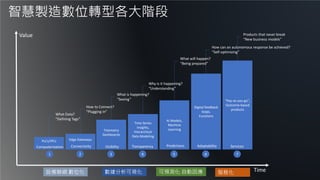

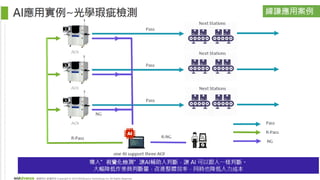

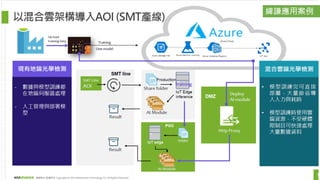

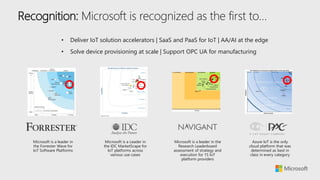

This document discusses trends in industrial IoT and how equipment companies can respond. It outlines Cathy Yeh's agenda which includes trends in industrial IoT and Microsoft's strategy, smart manufacturing use cases, and an innovative business model example using AOI cloud. It describes challenges facing global manufacturing from trends like shortened product lifecycles, rapidly changing operating environments, and industry ecosystem changes. It then provides examples of how industrial IoT solutions from Microsoft and partners can provide insights, reduce costs, and enable new revenue streams for customers through solutions like predictive maintenance and remote monitoring.