Mm210(5a)

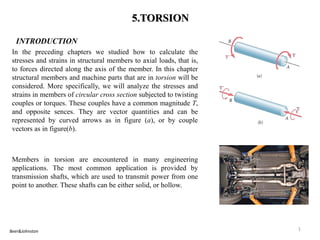

- 1. 5.TORSION INTRODUCTION In the preceding chapters we studied how to calculate the stresses and strains in structural members to axial loads, that is, to forces directed along the axis of the member. In this chapter structural members and machine parts that are in torsion will be considered. More specifically, we will analyze the stresses and strains in members of circular cross section subjected to twisting couples or torques. These couples have a common magnitude T, and opposite sences. They are vector quantities and can be represented by curved arrows as in figure (a), or by couple vectors as in figure(b). Members in torsion are encountered in many engineering applications. The most common application is provided by transmission shafts, which are used to transmit power from one point to another. These shafts can be either solid, or hollow. 1 Beer&Johnston

- 2. An important property of circular shafts should be noted: when a shaft is subjected to torsion, every cross section remains plane and undistorted. In other words, while the various sections along rotate through different amounts, each rotates as solid rigid slab.(bar square its warp do not remain plane.) Consider that attached fixed support at one end. If torque T applied end, will twist. Here it seen radial line located on distance x from end an angle ∅(푥). The ∅ ,so defined, called It depends position vary shown. important property of circular shafts should be noted: when a circular shaft is subjected to torsion, every cross section remains plane and undistorted. In other words, while the various cross sections along the shaft rotate through different amounts, each cross section rotates as a solid rigid slab.(when a bar of square cross section is subjected to torsion, its various cross sections warp and do not remain plane.) Consider a circular shaft that is attached to a fixed support at one end. If a torque T is applied to the other end, the shaft will twist. Here it is seen that a radial line located on the cross section at a distance x from the fixed end of the shaft will rotate through an angle ∅(푥). The angle ∅푥 ,so defined, is called the angle of twist. It depends on the position x and will vary along the shaft as shown. 2 5.1 TORSIONAL DEFORMATION OF A CIRCULAR SHAFT Beer&Johnston

- 3. We will now determine the distribution of shearing strains in a circular shaft length L and radius c which has been twisted through an angle ∅(푥). Detaching from cylinder ρ, we consider small square element formed by two adjacent circles straight lines traced on surface before any load is applied. As subjected to torsional load, deforms into rhombus (figure c). recall previous sections that strain γ given measured change angles sides element. Since defining considered here remain unchanged, must be equal between AB A´ B. can express arc AAas = Lγ. But other hand, have ρ . It follows Lγ , or 훾휌∅퐿 푚푎푐Where are both expressed radians. The equation obtained shows, at point torsion proportional also shows distance axis under consideration. Thus varies linearly with will now determine the distribution of shearing strains in a circular shaft of length L and radius c which has been twisted through an angle ∅(푥). Detaching from the shaft a cylinder of radius ρ, we consider the small square element formed by two adjacent circles and two adjacent straight lines traced on the surface of the cylinder before any load is applied. As the shaft is subjected to a torsional load, element deforms into a rhombus (figure c). We now recall from previous sections that the shearing strain γ in a given element is measured by the change in the angles formed by the sides of that element. Since the circles defining two of the sides of the element considered here remain unchanged, the shearing strain γ must be equal to the angle between lines AB and A´B. We can express the arc length AA´ as AA´= Lγ. But on the other hand, we have AA´= ρ. It follows that Lγ = ρ, or 훾= 휌∅ 퐿 and 훾푚푎푥= 푐∅ 퐿 Where γ and are both expressed in radians. The equation obtained shows, that the shearing strain γ at a given point of a shaft in torsion is proportional to the angle . It is also shows that γ is proportional to the distance ρ from the axis of the shaft to the point under consideration. Thus the shearing strain in a circular shaft varies linearly with the distance from the axis of the shaft 3 Beer&Johnston

- 4. 5.2 THE TORSION FORMULA Recalling the Hooke’s law for shearing stress and strain we write, where G is the modulus of rigidity or shear modulus of the material. Using previous equation and hooke’s law we can write, 휏= 휌 푐 휏푚푎푥 (1) The equation expresses the shear-stress distribution as a function of the radial position ρ of the element; in other words, it defines the stress distribution in terms of the geometry of the shaft. We recall that the sum of the elementary forces exerted on any cross section of the shaft must be equal to the magnitude T on the torque exerted on the shaft: 휌휏푑퐴=푇 (2) Substituting for 휏 from (1) into (2) we write 푇= 휌휏푑퐴= 휏푚푎푥 푐 휌2푑퐴 4 Beer&Johnston

- 5. THE TORSION FORMULA 푇= 휌휏푑퐴= 휏푚푎푥 푐 휌2푑퐴 The integral in this equation depends only on the geometry of the shaft. It represents the polar moment of inertia of the shaft’s cross-sectional area computed about the shaft’s longitudinal axis. We will symbolize its value as J, and therefore the above equation can be written in a more compact form, namely 휏푚푎푥= 푇푐 퐽 where 휏푚푎푥 = the maximum shear stress in the shaft, which occurs at the outer surface T = the resultant internal torque acting at the cross section. Its value is determined from the method of sections and the equation of moment equlibrium applied about the shaft’s longitudinal axis J = the polar moment of inertia of the cross-sectional area c = the outer radius of the shaft The shear stress at the intermediate distance ρ can be determined from a similar equation 휏= 푇휌 퐽 Either of the two above equations is often referred to as the torsion formula. 5

- 6. 6 Polar moment of inertia for solid cross section: Polar moment of inertia for tubular cross section: 퐽= 휋 2 푐4 퐽= 휋 2 푐24−푐14 Typical elements, when isolated from the shaft in figure, must be subjected to shear stresses directed as shown. Hence, not only does the internal torque T develop a linear distribution of shear stress along each radial line in the plane of the cross-sectional area, but also an associated shear-stress distribution is developed along an axial plane.

- 7. Example 5.1(beer&johnston) 7 A hollow cylindrical steel shaft is 1.5 m long and has inner and outer diameters respectively equal to 40 and 60 mm. (a) what is the largest torque that can be applied to the shaft if the shearing stress is not to exceed 120 MPa? b) what is the corresponding minimum value of the shearing stress in the shaft?

- 8. Example 5.2(hibbeler) 8 The pipe shown in the figure has an inner diameter of 80 mm and an outer diameter of 100 mm. If its end is tightened against the support at A using a torque wrench at B, determine the shear stress developed in the material at the inner and outer walls along the central portion of the pipe when the 80-N forces are applied to the wrench.

- 9. 9 The torsion formulas were derived for a shaft of uniform circular cross section subjected to torques at its ends. However, they can also be used for a shaft of variable cross section or for a shaft subjected to torques at locations other than its ends. The distribution of shearing stresses in a given cross section S of the shaft is obtained from torsion formula, Tc/J, where J denotes the polar moment of inertia of that section, and where T represents the internal torque in that section. The value T is obtained by drawing the free-body diagram of the portion of shaft located on one side of the section and writing that the sum of torques applied to that portion, including the internal torque T, is zero. If the absolute maximum torsional stress is to be determined, then it becomes important to find the location where the ratio Tc/J is maximum. Beer&Johnston

- 10. 10 Shaft BC is hollow with inner and outer diameters of 90 mm and 120 mm, respectively. Shafts AB and CD are solid and of diameter d. For the loading shown, determine a) the maximum and minimum shearing stress in shaft BC, b) the required diameter d of shafts AB and CD if the allowable shearing stress in these shafts is 65 MPa. Example 5.3 (Beer&Johnston)

- 11. 11 The solid 30-mm-diameter shaft is used to transmit the torques applied to the gears. Determine the absolute maximum shear stress on the shaft. Example 5.4 (Beer&Johnston)

- 12. 12 The motor delivers a torque of 50 N.m to the shaft AB. This torque is transmitted to shaft CD using the gears at E and F. Determine the equilibrium torque T’ on shaft CD and the maximum shear stress in each shaft. The bearings B, C, and D allow free rotation of the shafts. Example 5.5 (Hibbeler)

- 13. 5.3 POWER TRANSMISSION Shafts and tubes having cross sections are often used to transmit power developed by a machine. When used for this purpose they are subjected to torques that depend on the power generated by the machine and the angular speed of the shaft. Power is defined as the work performed per unit of time. The work transmitted by a rotating shaft equals the torque applied times the angle of rotation. Therefore, if during an instant of time dt an applied torque T will cause the shaft to rotate dθ, then the instantaneous power is, 푃= 푇푑휃 푑푡 Since the shaft’s angular velocity 휔=푑휃/푑푡, we can also express the power as, 푃=푇휔 13

- 14. POWER TRANSMISSION In the SI system, power is expressed in watts when torque is measured in newton-meters (N.m) and ω is in radians per second (rad/s). In the FPS system, the basic units of power are foot-pounds per second; however, horsepower (hp) is often used in engineering practice, where 1 ℎ푝=550 ft.lb/s For machinery, the frequency of a shaft’s rotation, f, is often reported. This is a measure of the number of revolutions or cycles the shaft makes per second and is expressed in hertz (1 Hertz = 1 cycle/s). Since 1 cycle = 2휋 rad, then 휔=2휋푓 and the above equation for power becomes 푃=2휋푓푇 Shaft design When the power transmitted by a shaft and its frequency of rotation are known, the torque developed in the shaft can be determined from the equation above, that is 푇=푃/2휋푓. Knowing T and the allowable shear stress for the material, 휏푎푙푙표푤, we can determine the size of the shaft’s cross section using the torsion formula, provided the material behavior is linear-elastic. Specifically, the design or geometric parameter J/c becomes 퐽 푐 = 푇 휏푎푙푙표푤 For a solid shaft, 퐽=휋/2푐4, and thus, upon substitution, a unique value for the shaft’s radius c can be determined. If the shaft is tubular, so that design permits a wide range of possibilities for the solution since an arbitrary choice can be made for either, 푐0 or 푐푖 and the other radius is determined from the torsion formula. 14

- 15. 15 The drive shaft AB of an automobile is to be designed as a thin-walled tube. The engine delivers 150 hp when the shaft is turning at 1500 rev/min. Determine the minimum thickness of the shaft’s wall if the shaft’s outer diameter is 2.5 in. The material has an allowable shear stress of 휏푎푙푙표푤=7 ksi Example 5.6 (Hibbeler)

- 16. 16 The motor A develops a power of 300 W and turns its connected pulley at 90 rev/min. Determine the required diameters of the steel shafts on the pulleys at A and B if the allowable shear stress is 휏푎푙푙표푤= 85 MPa. Example 5.7 (Hibbeler)