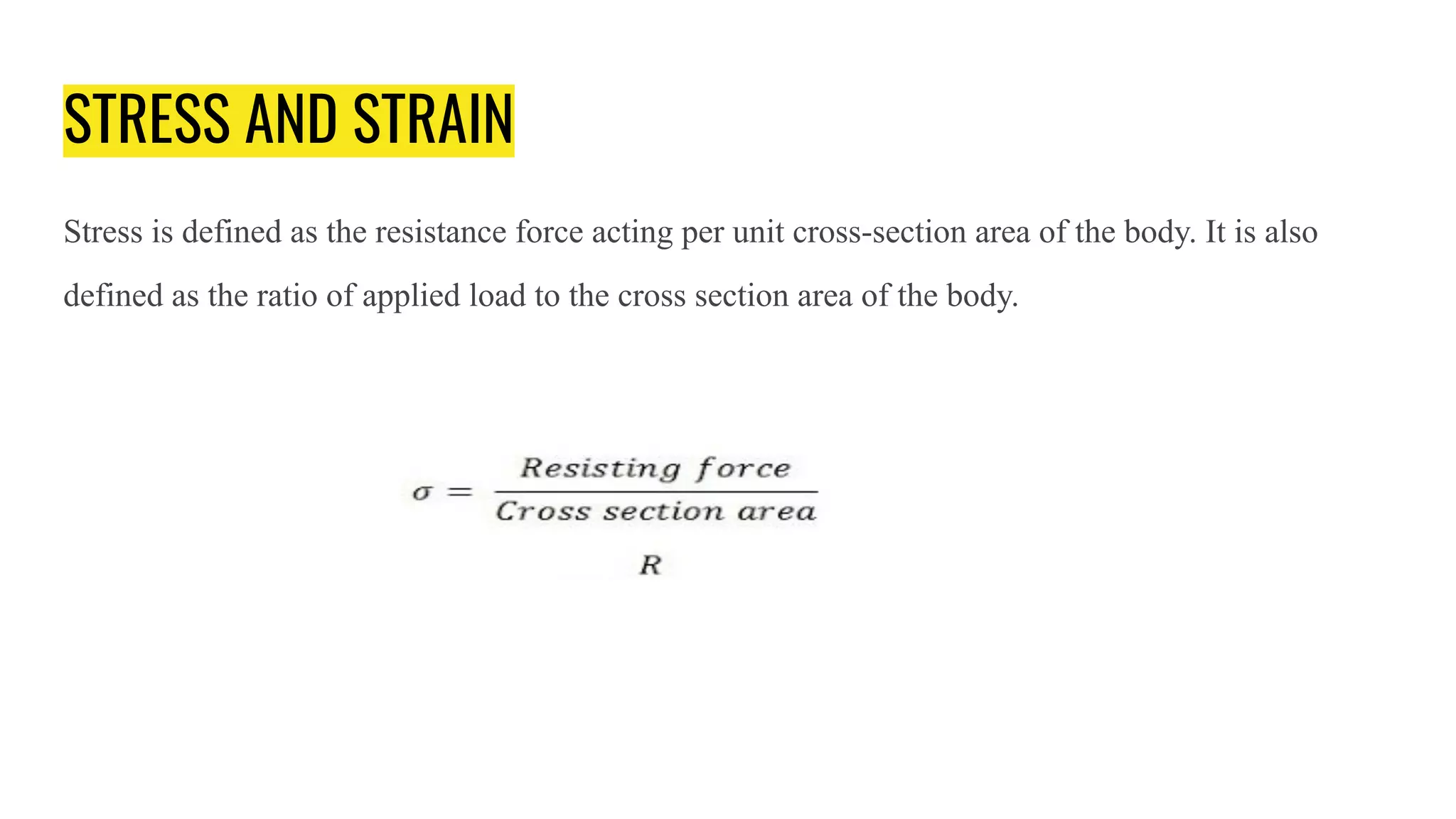

- Stress is defined as the resistance force acting per unit cross-section area of a body. It is calculated as the applied load divided by the cross-sectional area.

- The main types of stress are normal stress, shear stress, tensile stress, and compressive stress. Tensile stress results from pulling forces, while compressive stress is from pushing forces.

- Shear stress acts tangentially across a surface. Elasticity refers to a material's ability to deform under stress but return to its original shape when the stress is removed, as described by Hooke's law.