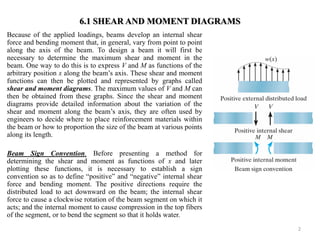

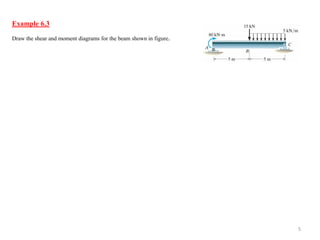

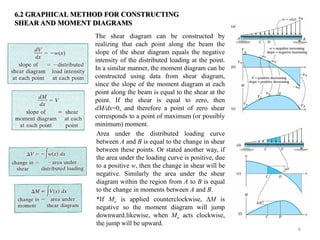

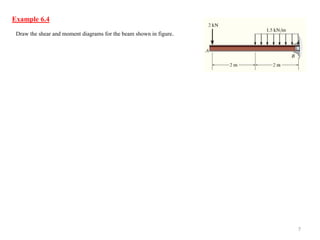

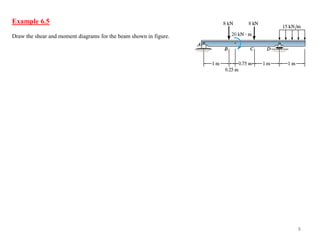

This document discusses bending and constructing shear and moment diagrams for beams. It defines beams as long, straight members that support loads applied perpendicular to their axis. Beams can be simply supported, cantilevered, or overhanging. Shear and moment diagrams show the variation of shear and bending moment along a beam under applied loads. The document establishes sign conventions and provides examples of drawing shear and moment diagrams for various loaded beams through a graphical method.