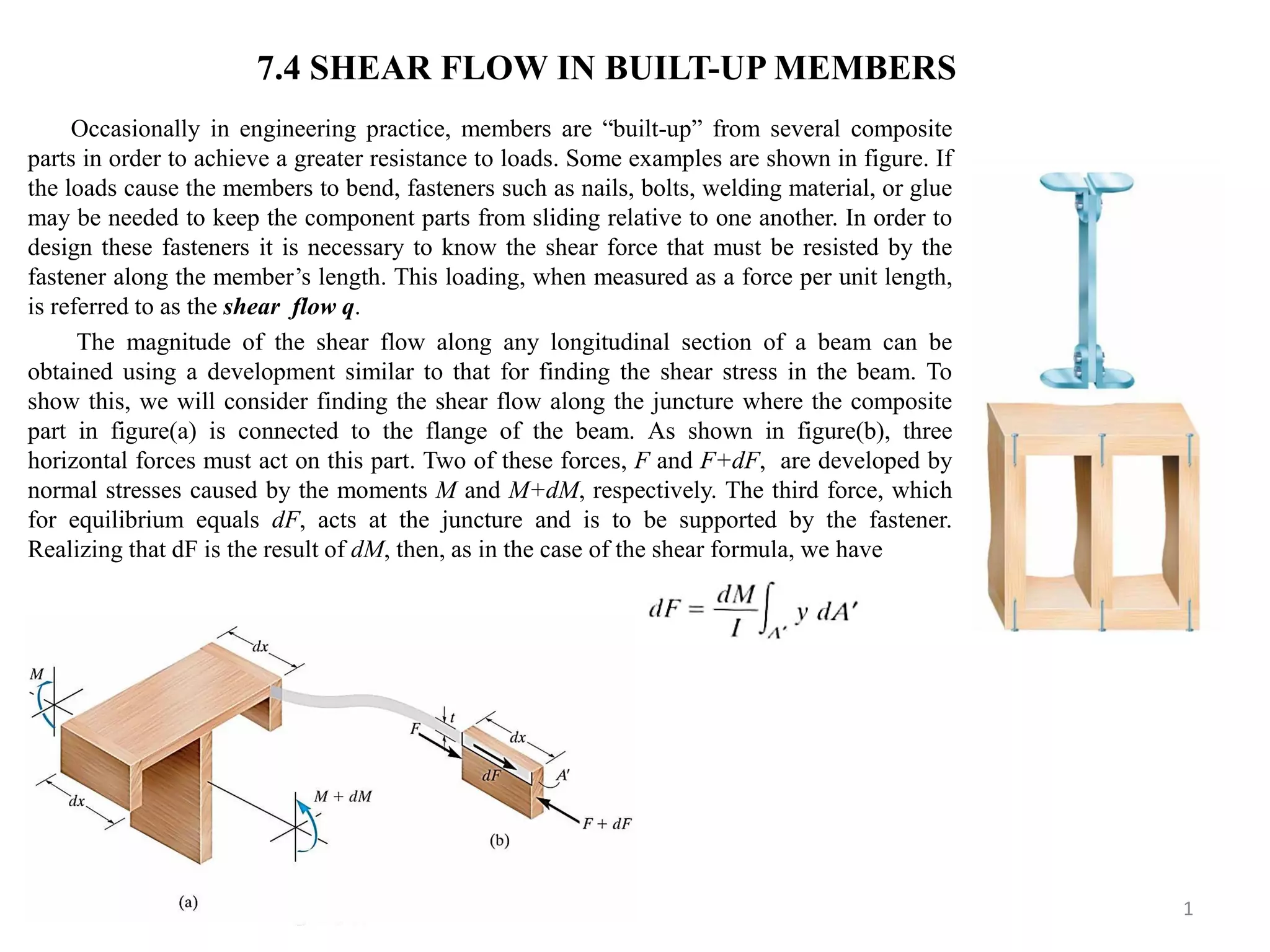

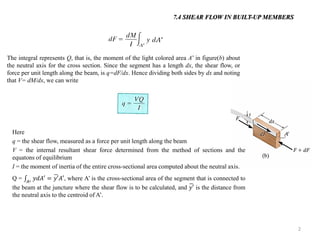

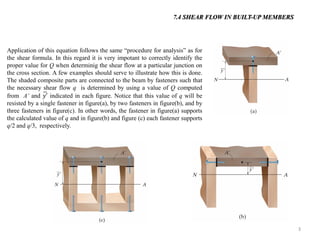

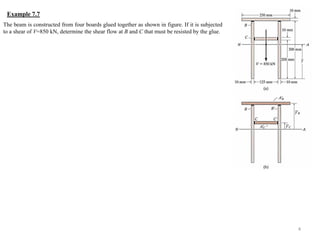

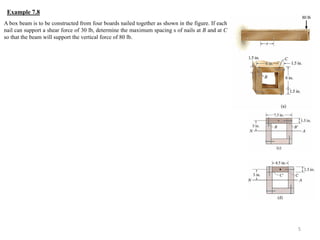

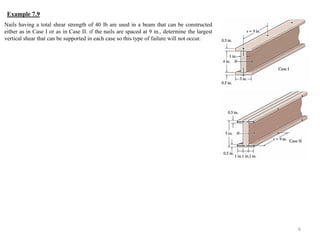

This document discusses shear flow in built-up members, which are structural members constructed from composite parts joined together. It provides a formula to calculate the shear flow along the junction between composite parts based on the internal shear force, moment of inertia, and moment of a segment's area about the neutral axis. Examples are given to demonstrate calculating shear flow at specific points that must be resisted by fasteners joining the composite parts.