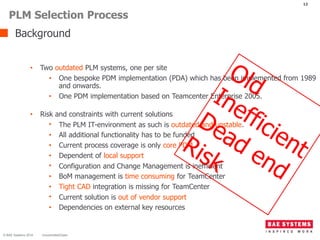

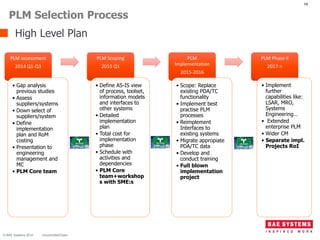

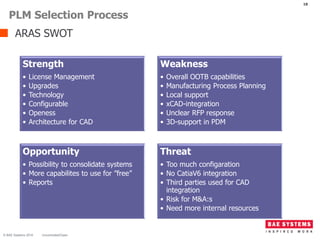

BAE Systems Sweden is engaged in a PLM selection process due to outdated systems and inefficiencies, examining vendor options like Systemx and Systemy to replace legacy solutions. The organization aims to consolidate PLM systems while assessing cost, functionality, and alignment with business needs. A detailed implementation plan is projected from 2015 to 2017, focusing on enhanced capabilities and support for long product lifecycles.