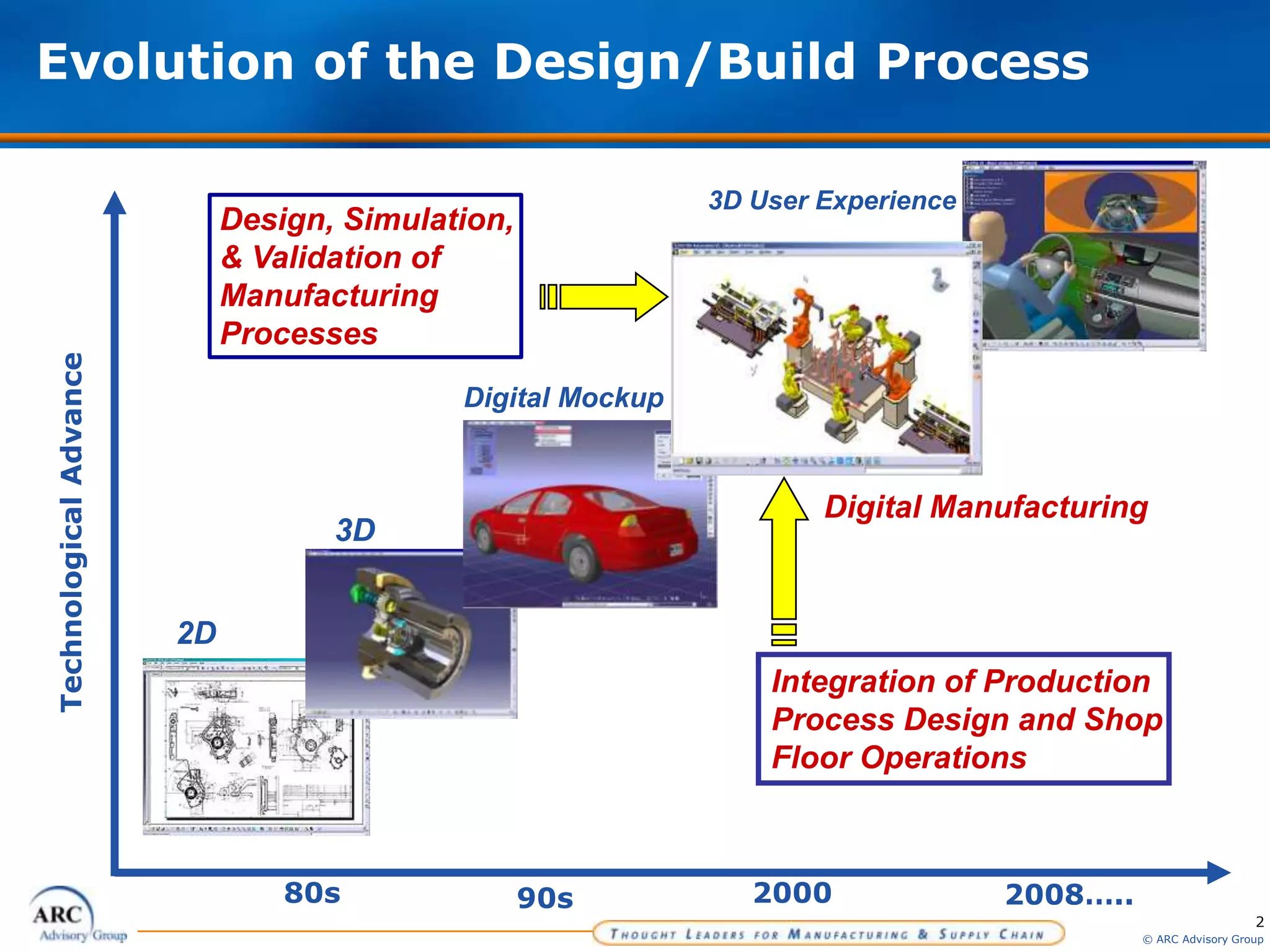

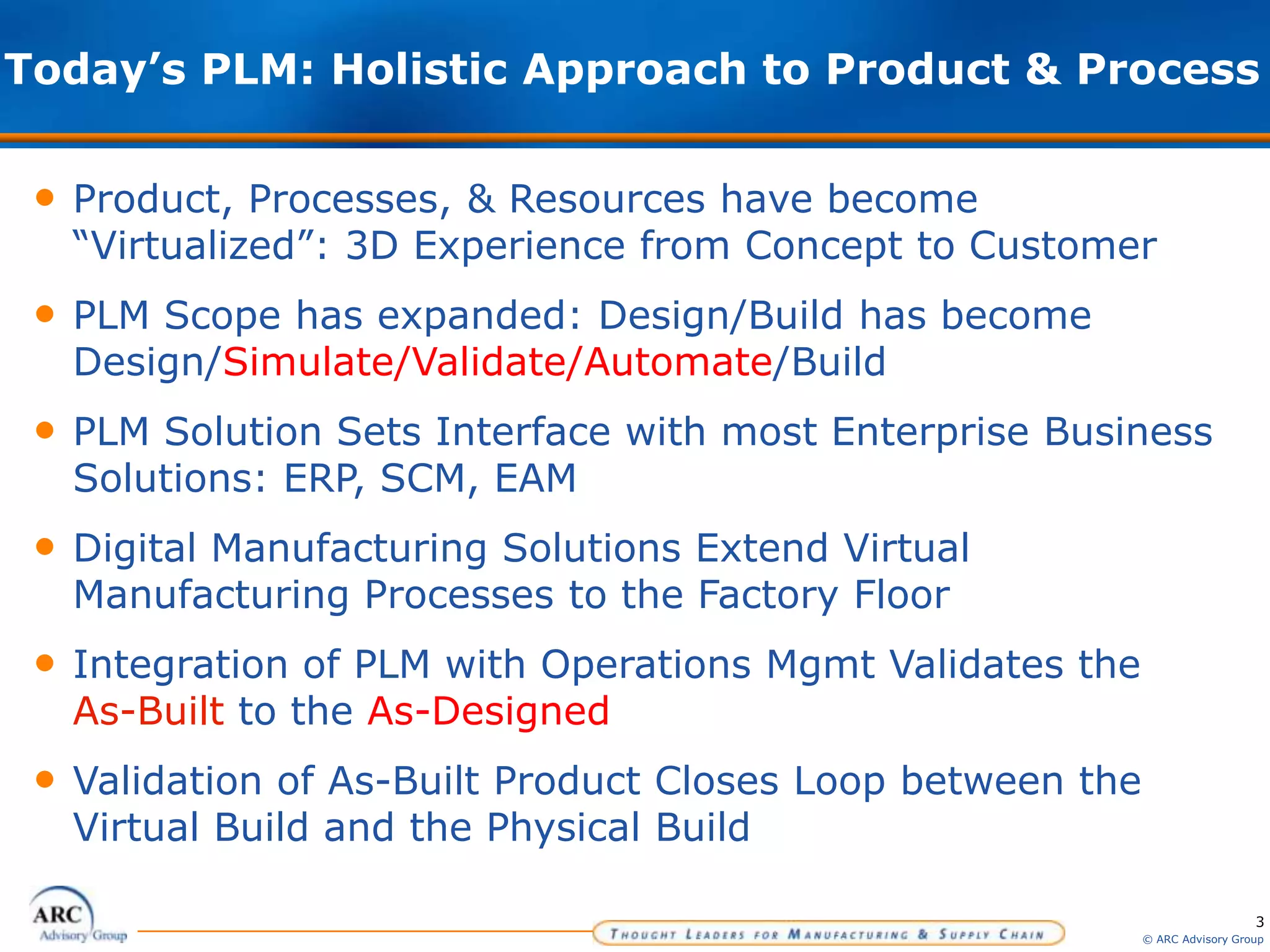

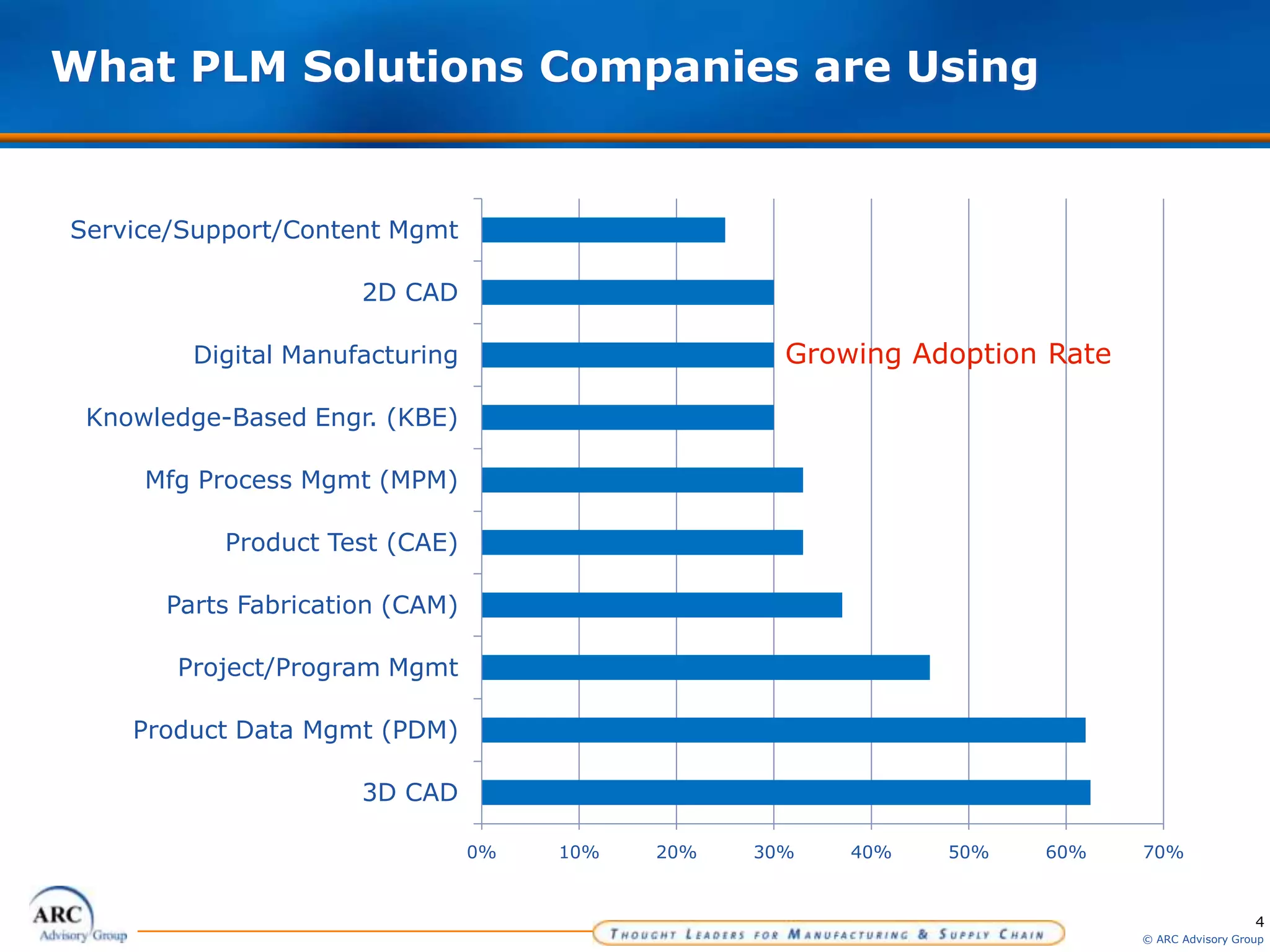

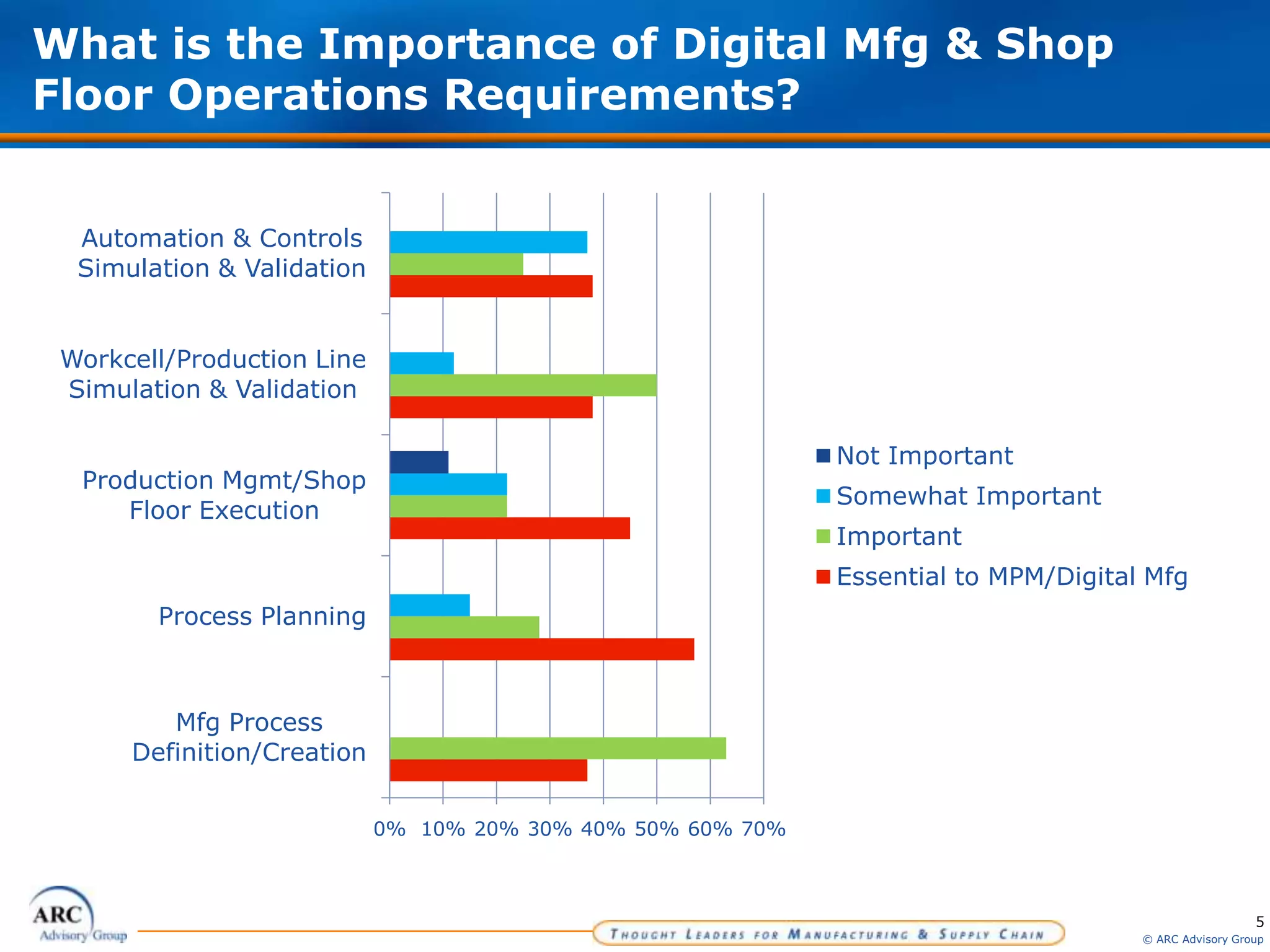

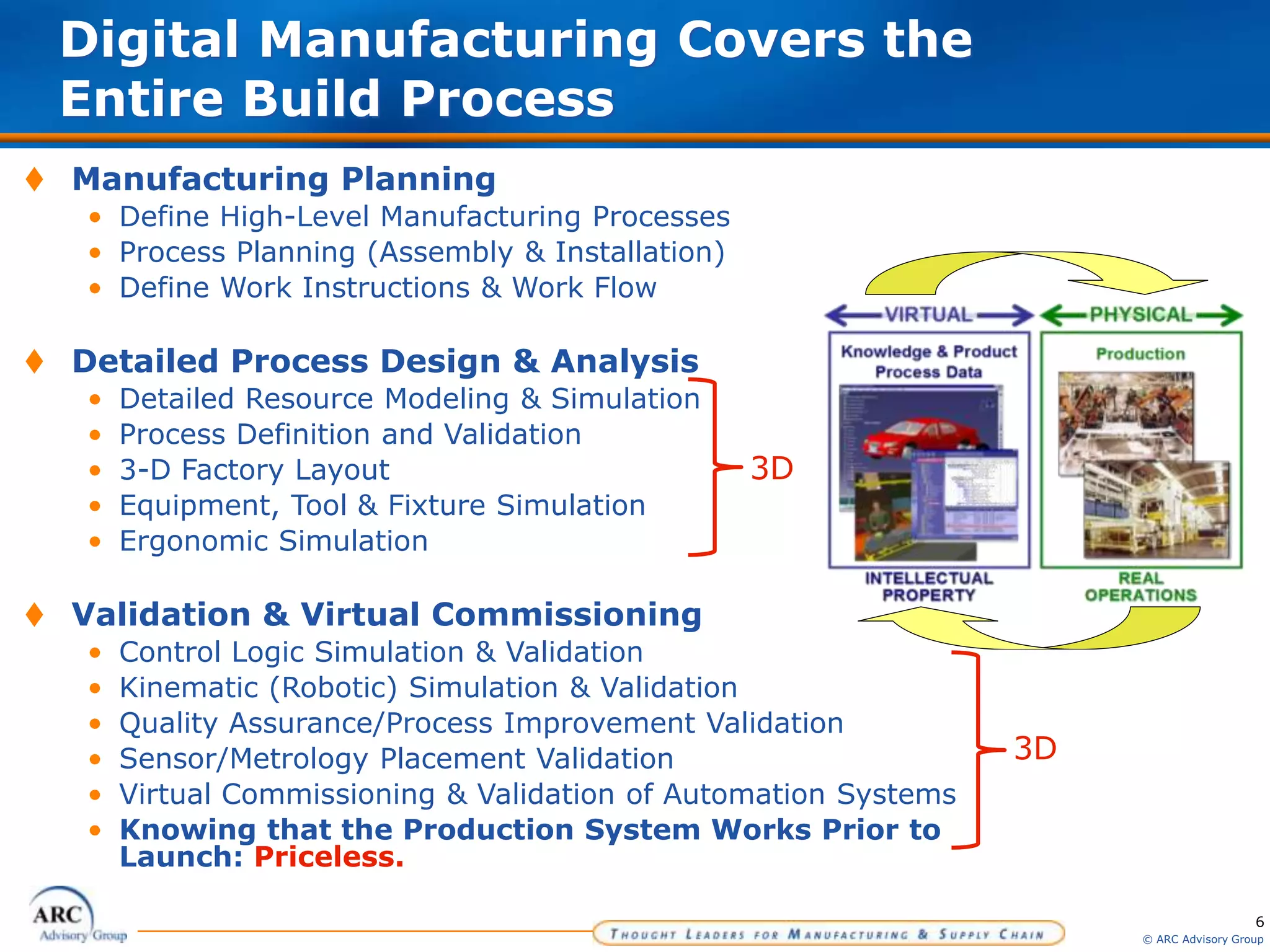

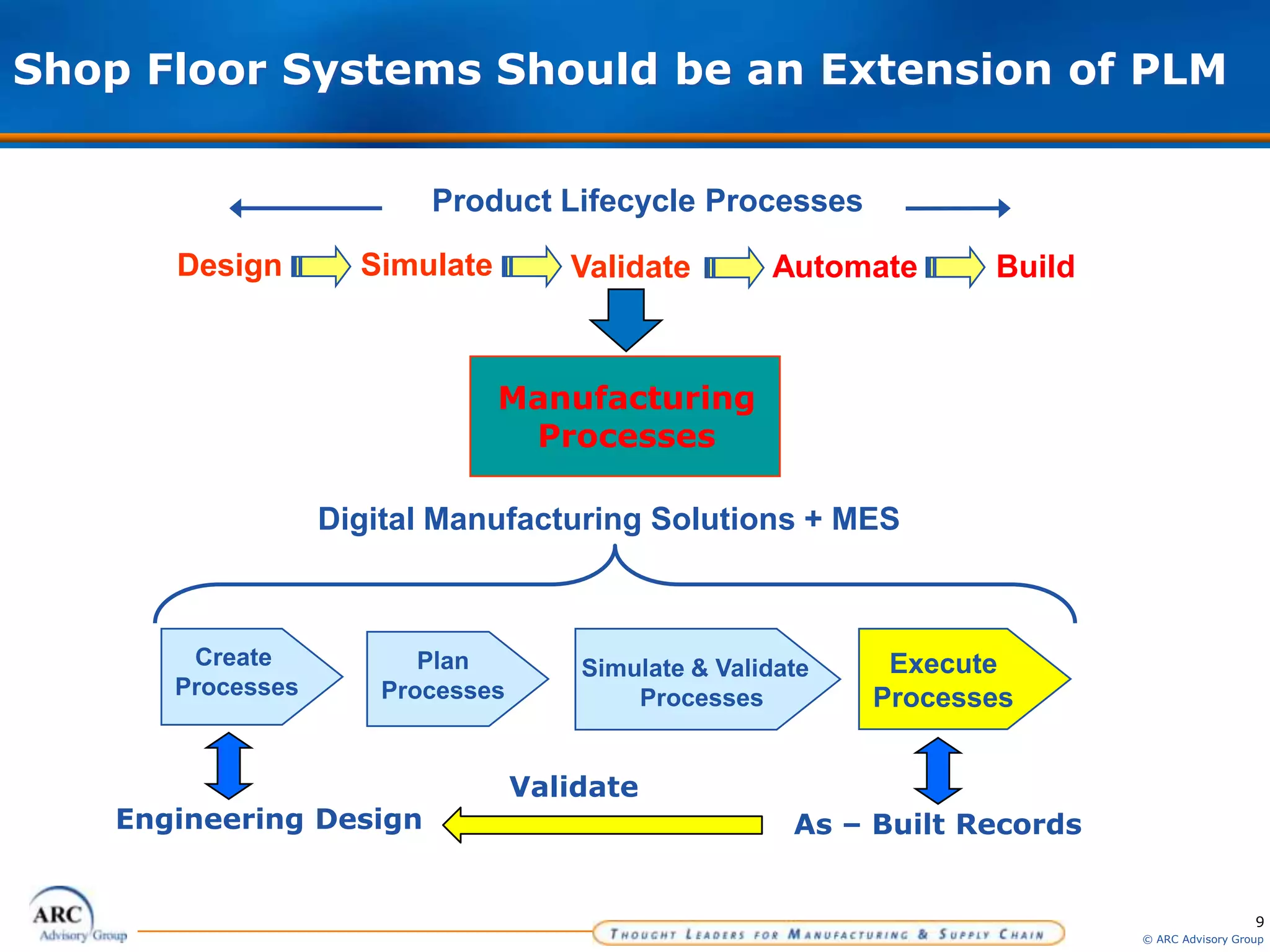

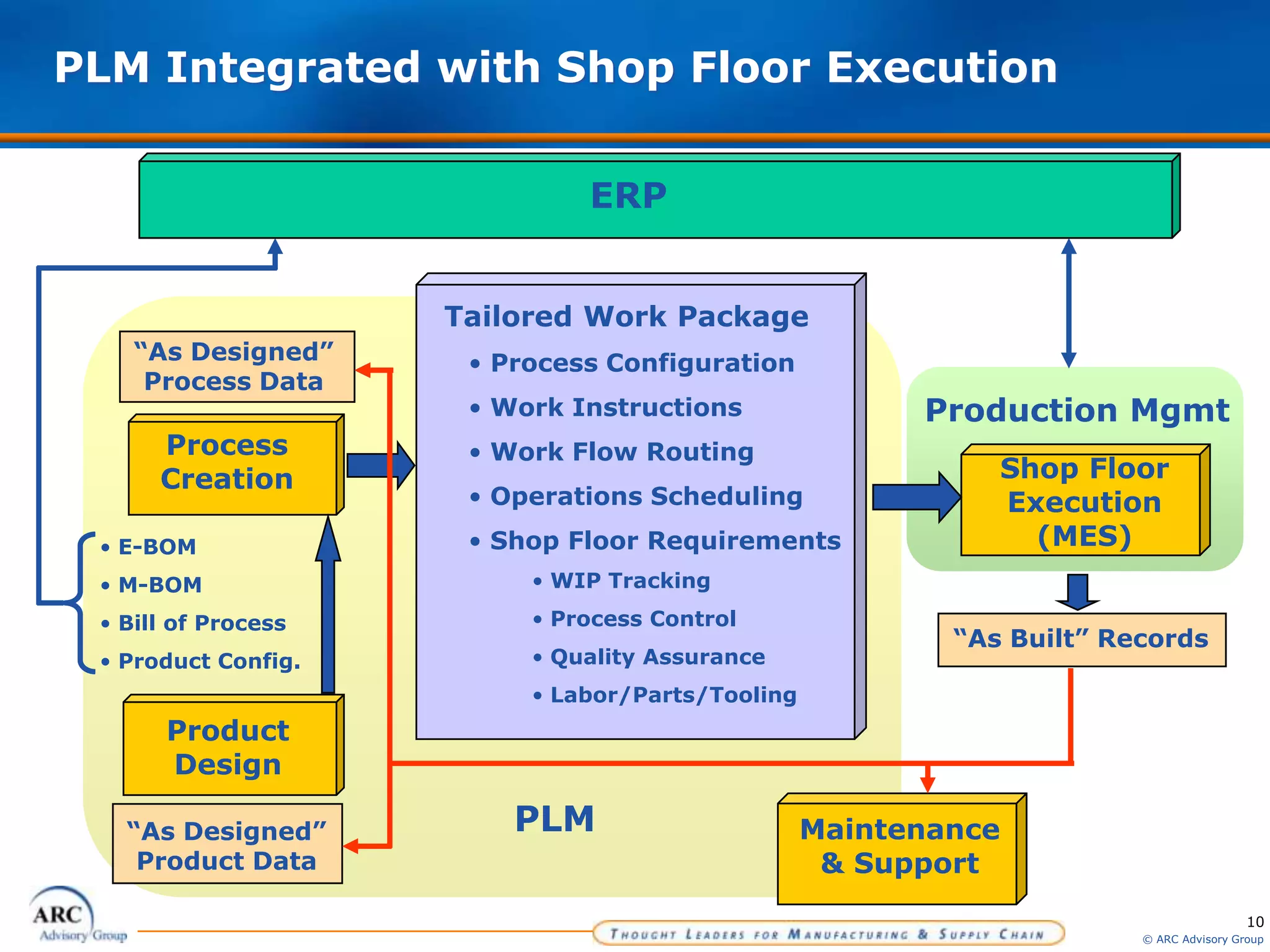

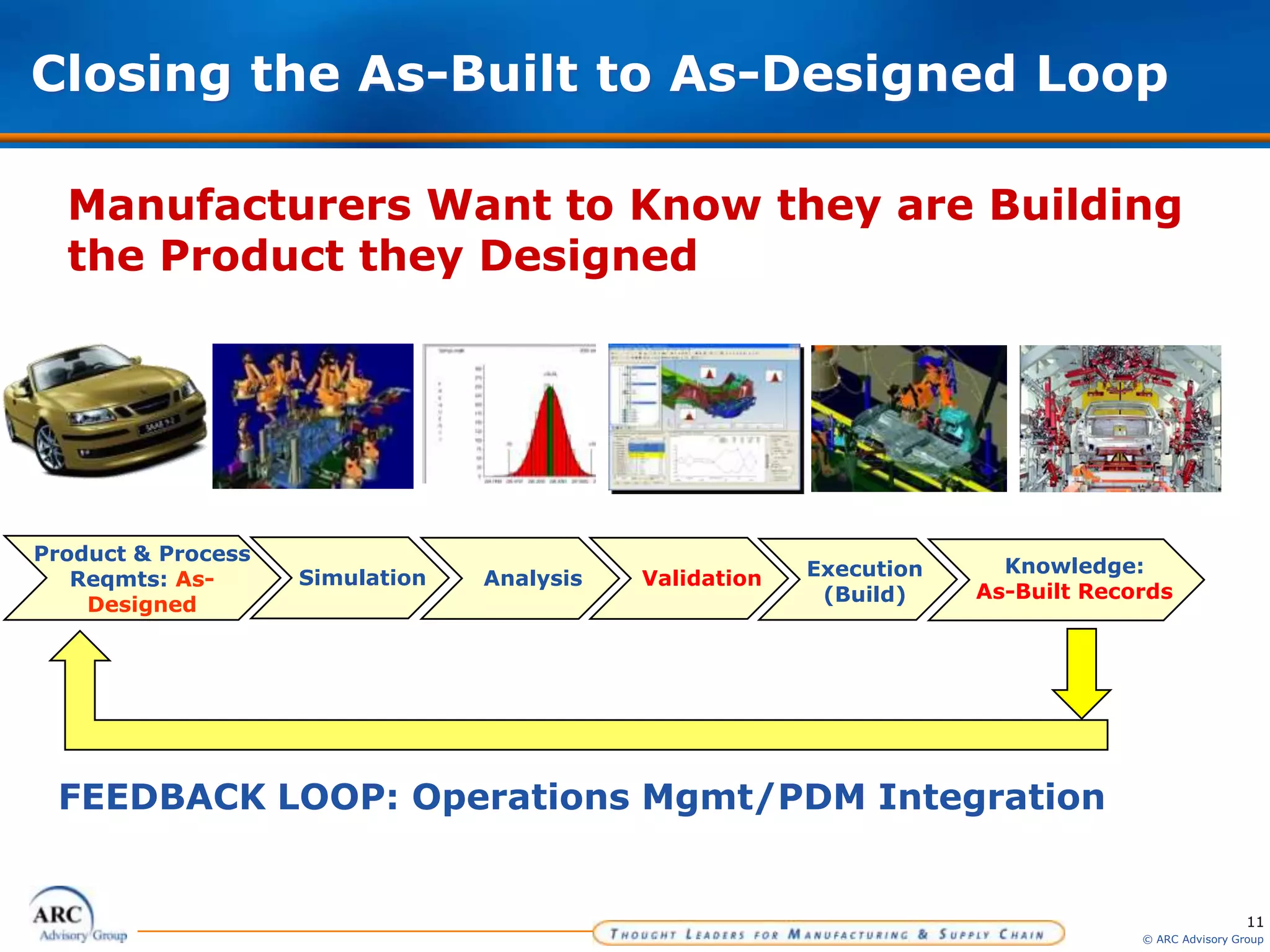

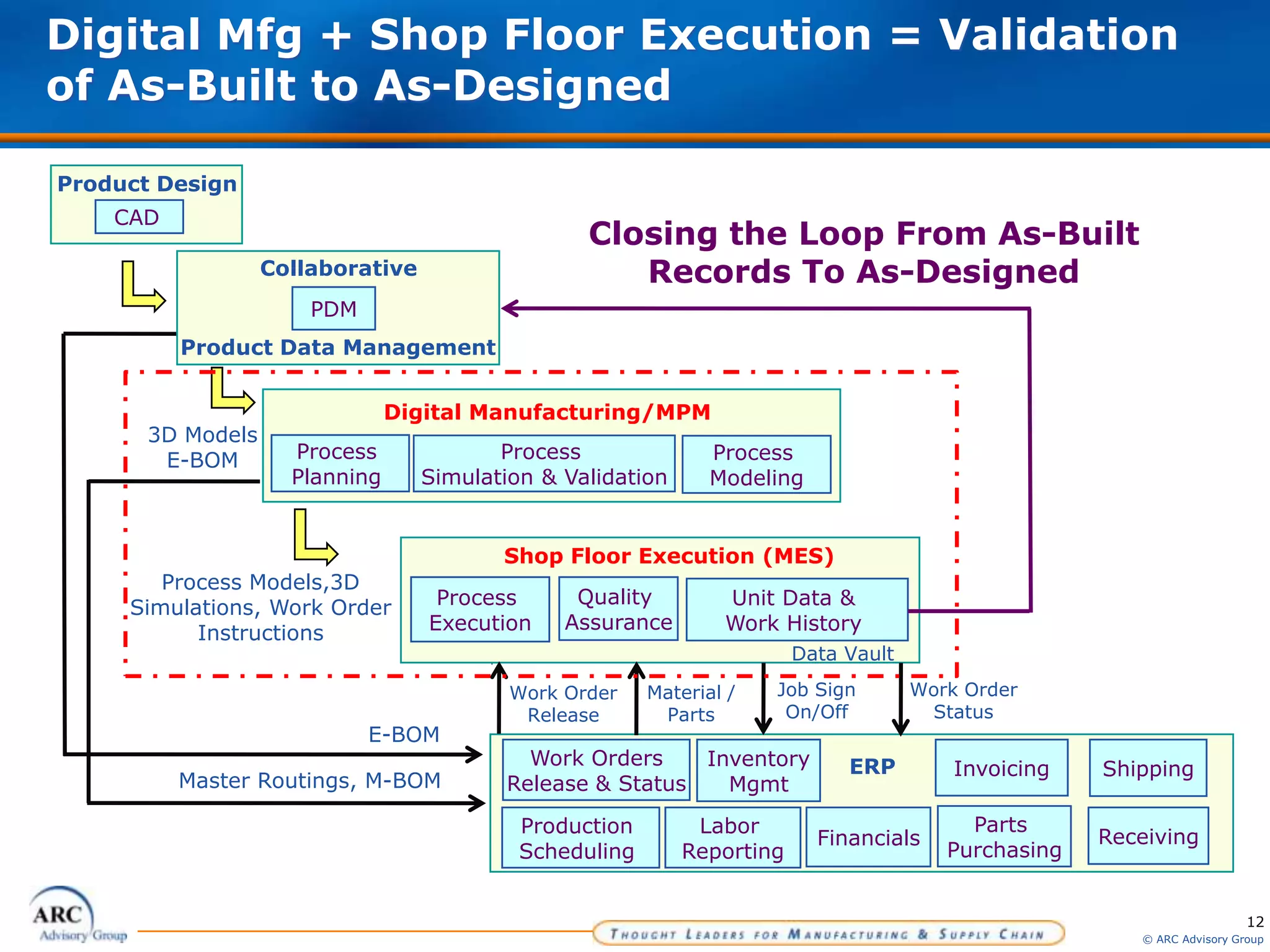

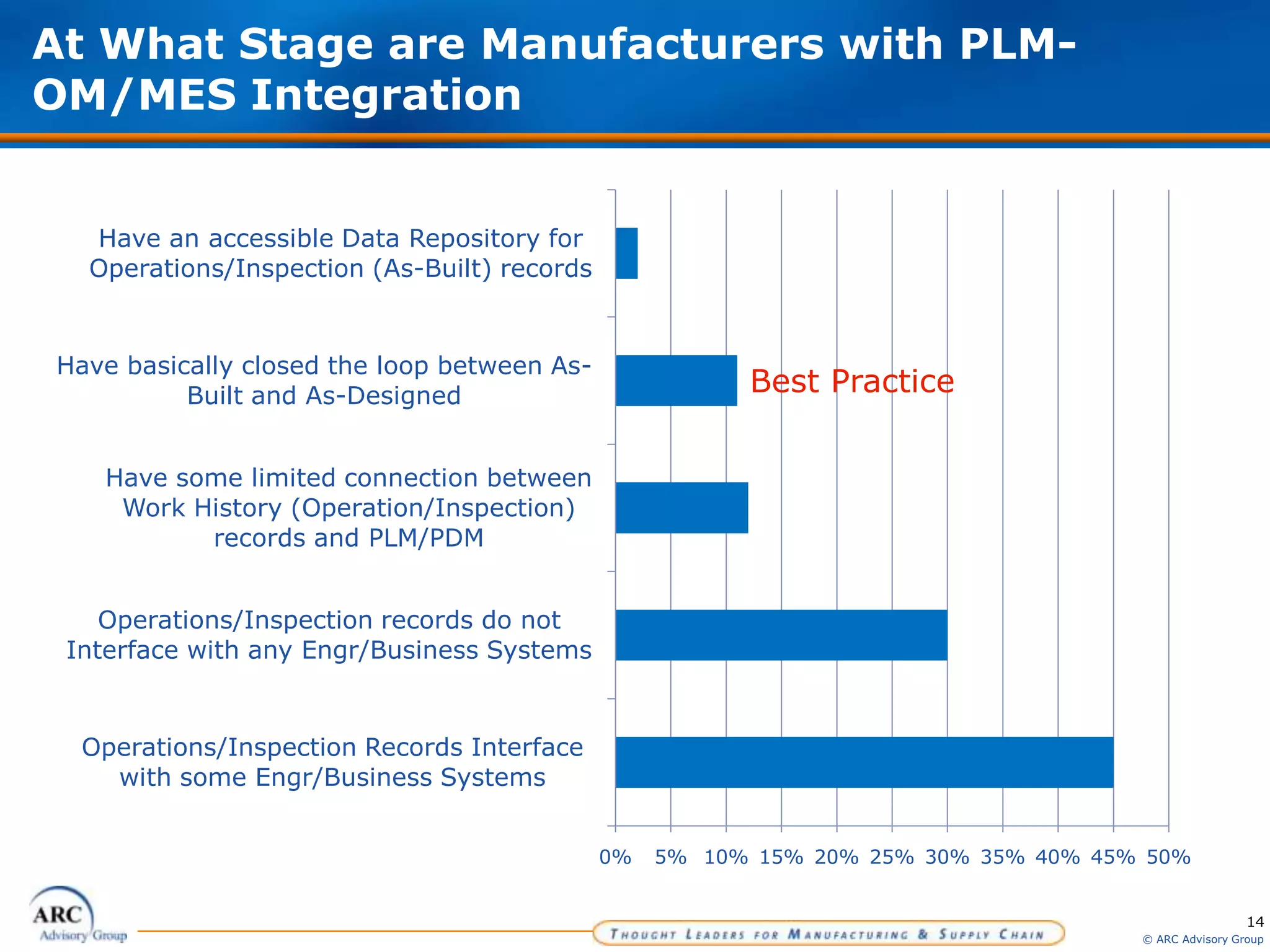

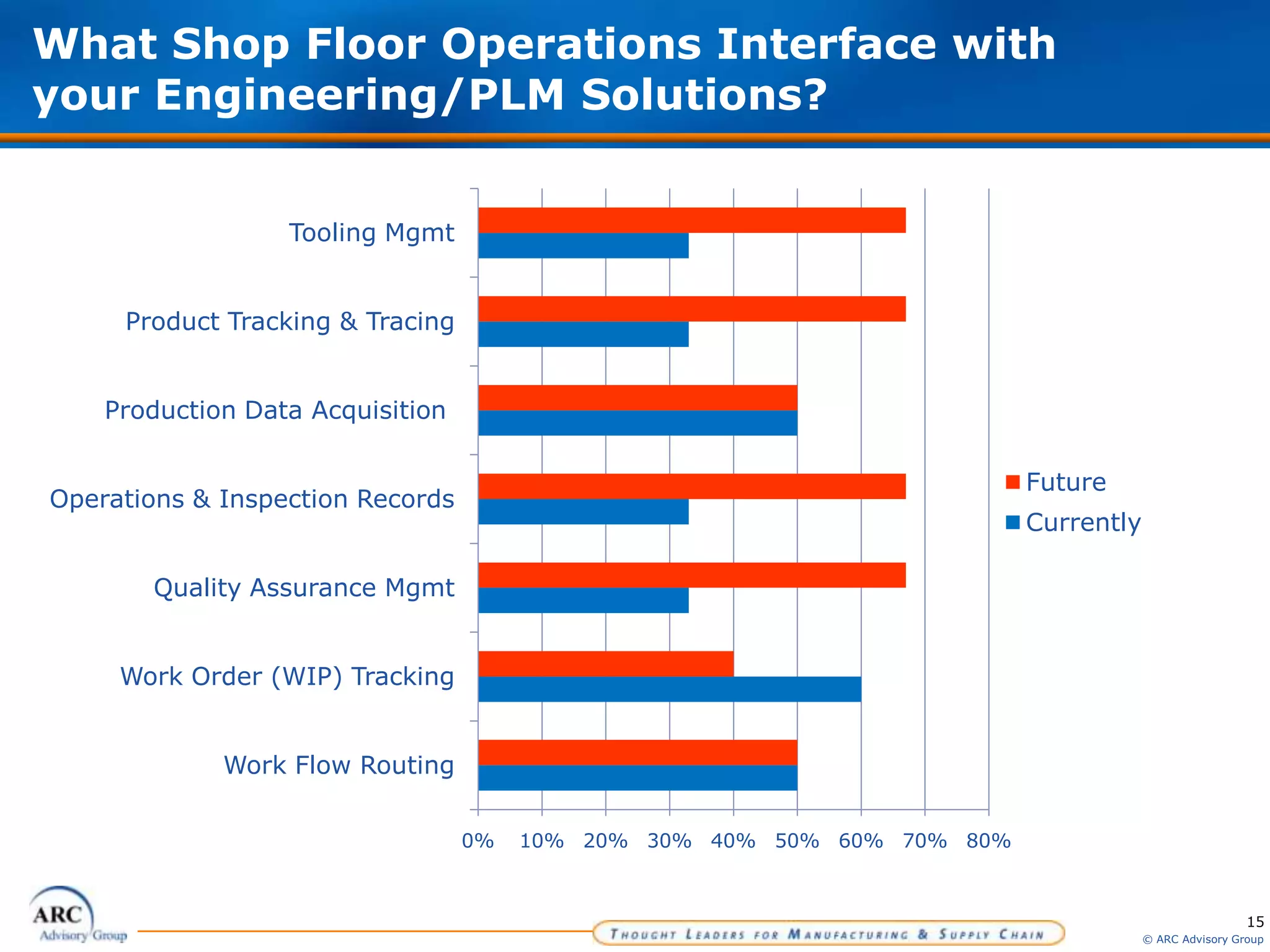

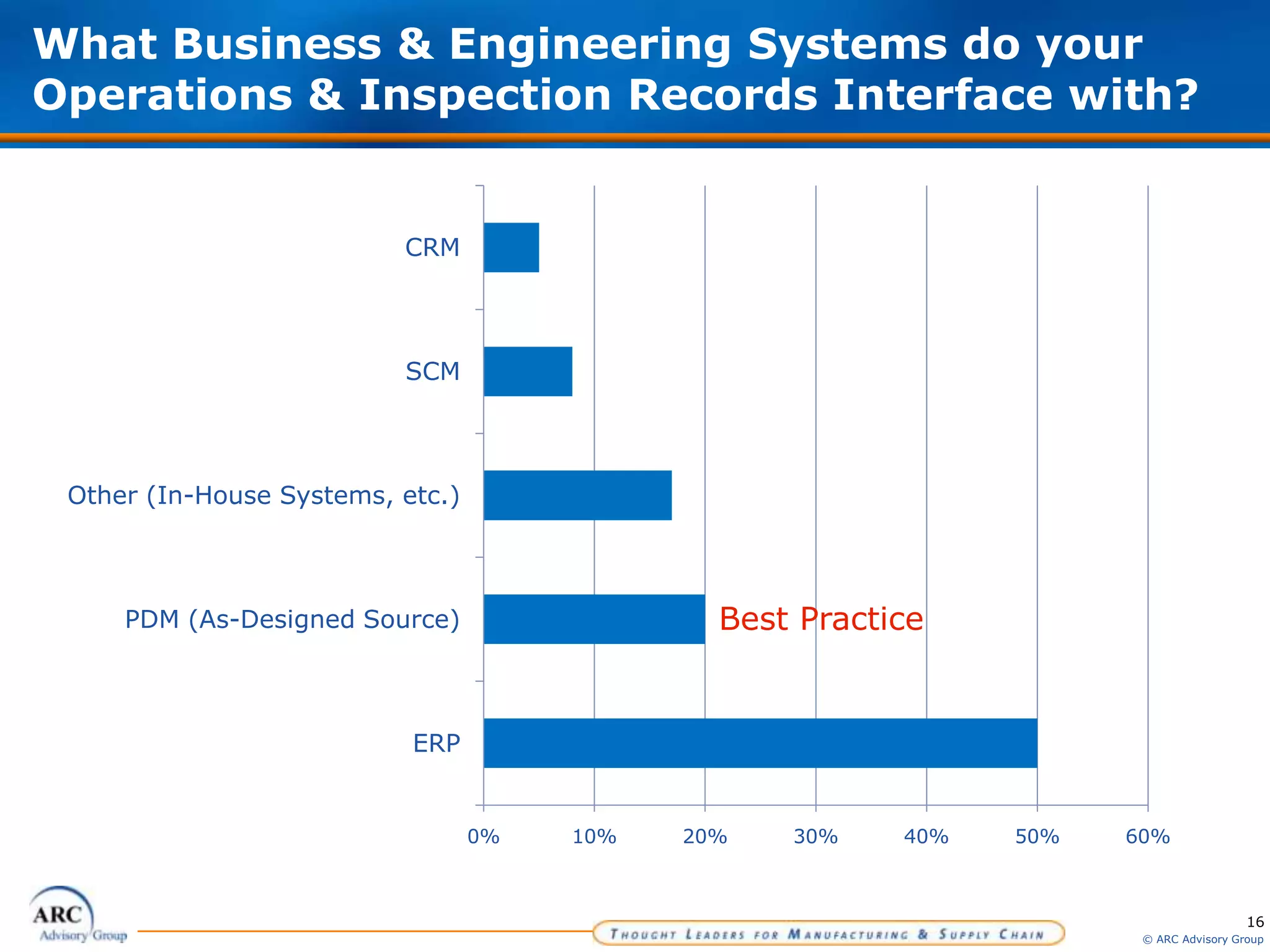

The document discusses the integration of Product Lifecycle Management (PLM) with shop floor operations, highlighting the shift from traditional design/build processes to a more comprehensive approach that includes design, simulation, validation, and automation. It emphasizes the importance of validating the as-built products against the as-designed specifications to ensure manufacturing accuracy and efficiency. Additionally, it outlines the evolving tools and technologies that facilitate this integration and the need for manufacturers to adopt a more holistic view of product and process design throughout the lifecycle.