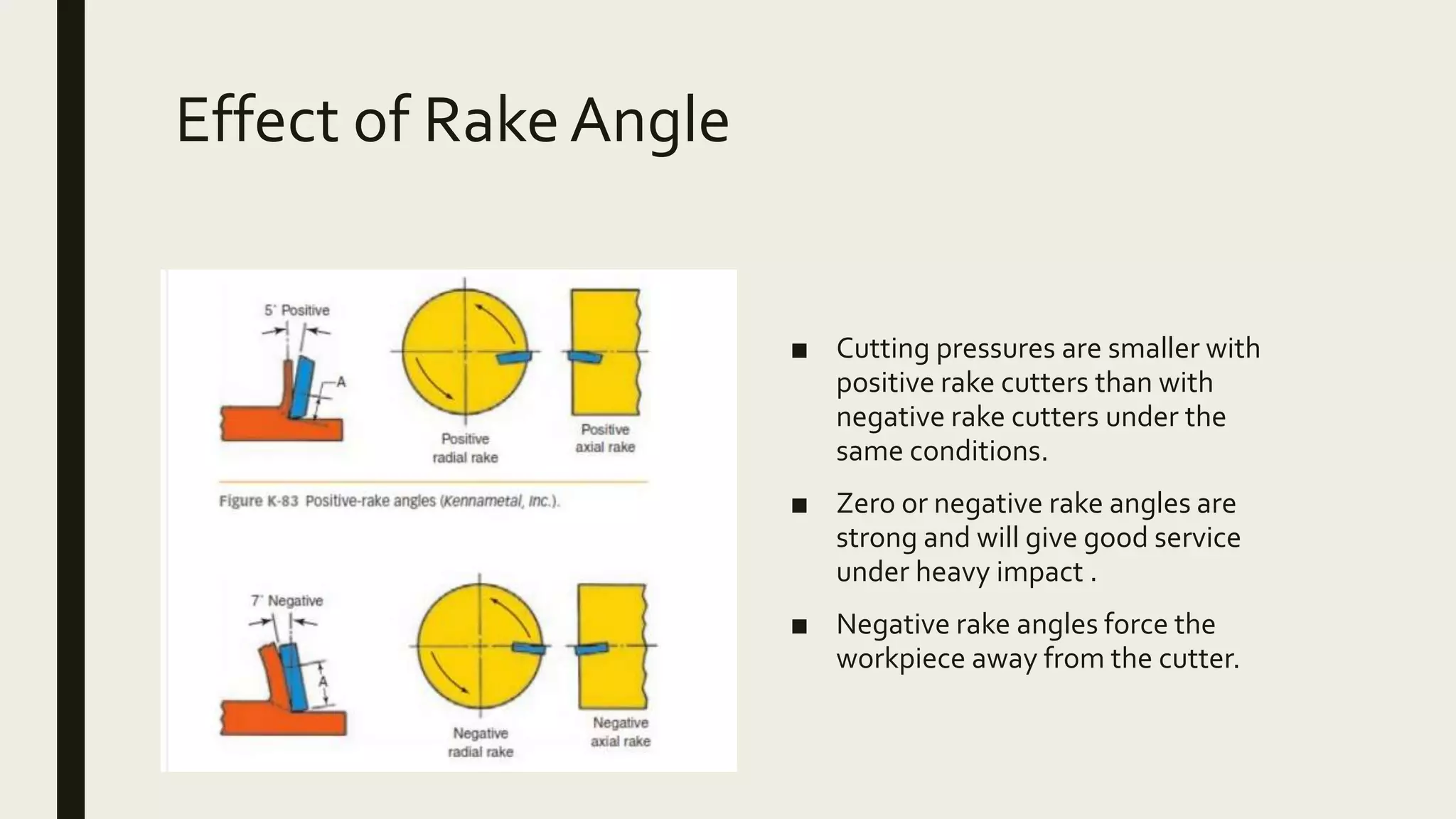

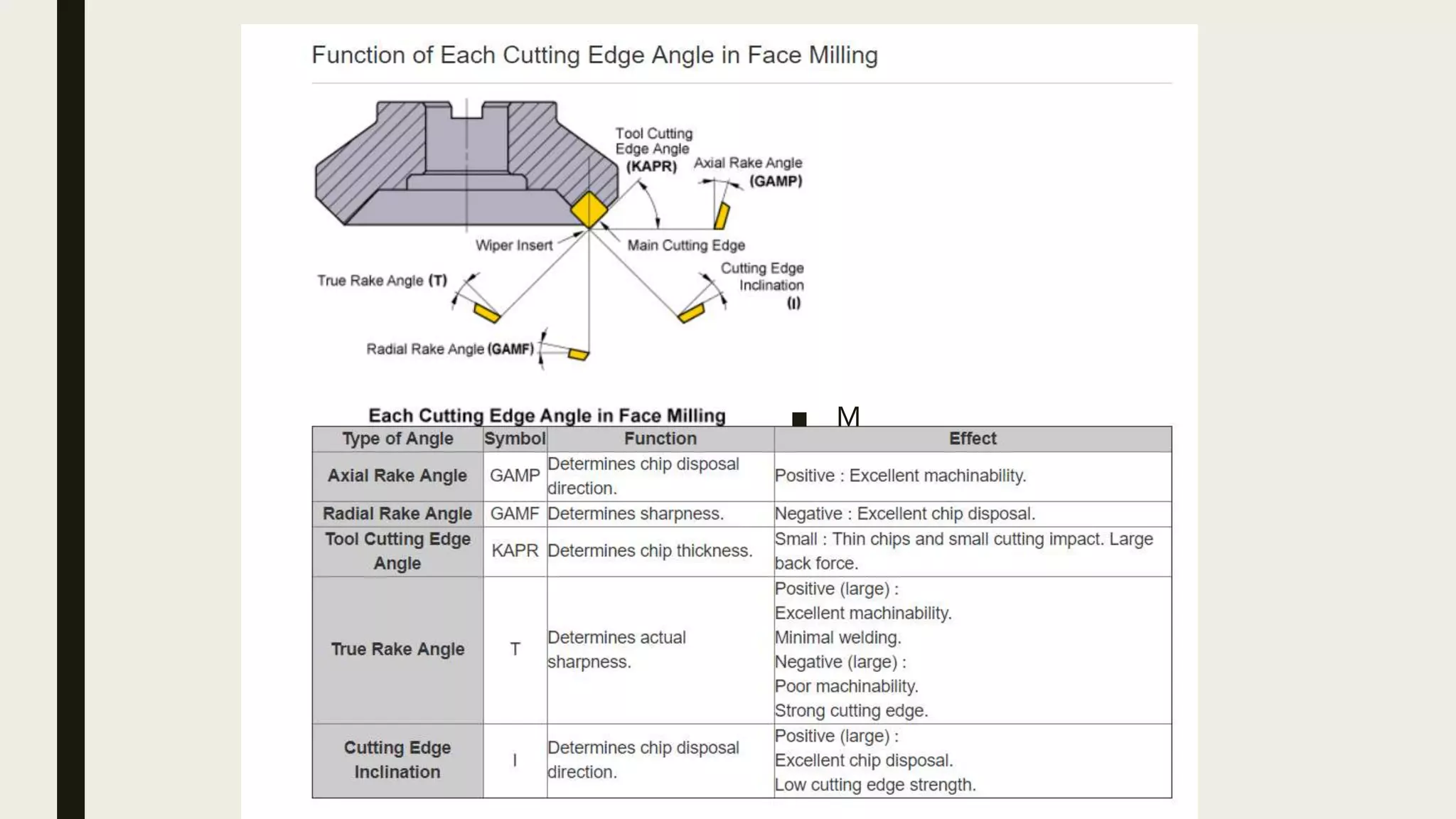

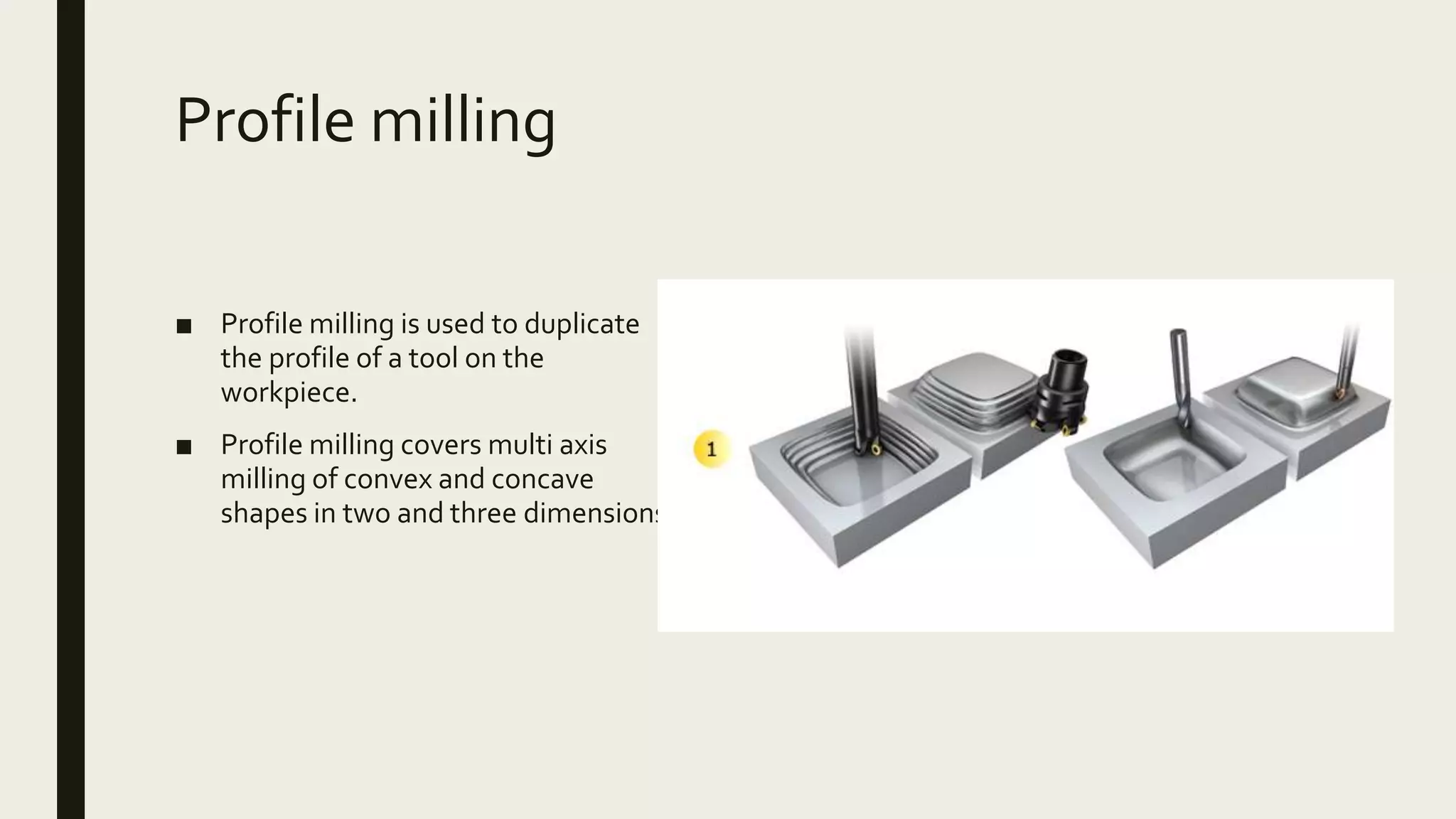

This document summarizes different types of milling machines and milling processes. It discusses column and knee milling machines, which are commonly used for small shop work. It also describes different milling processes like peripheral milling, up milling, down milling, and face milling. Key factors that influence these milling processes like cutter geometry, lead angle, and rake angle are explained. Guidelines for milling operations to minimize vibrations and ensure rigidity are also provided.