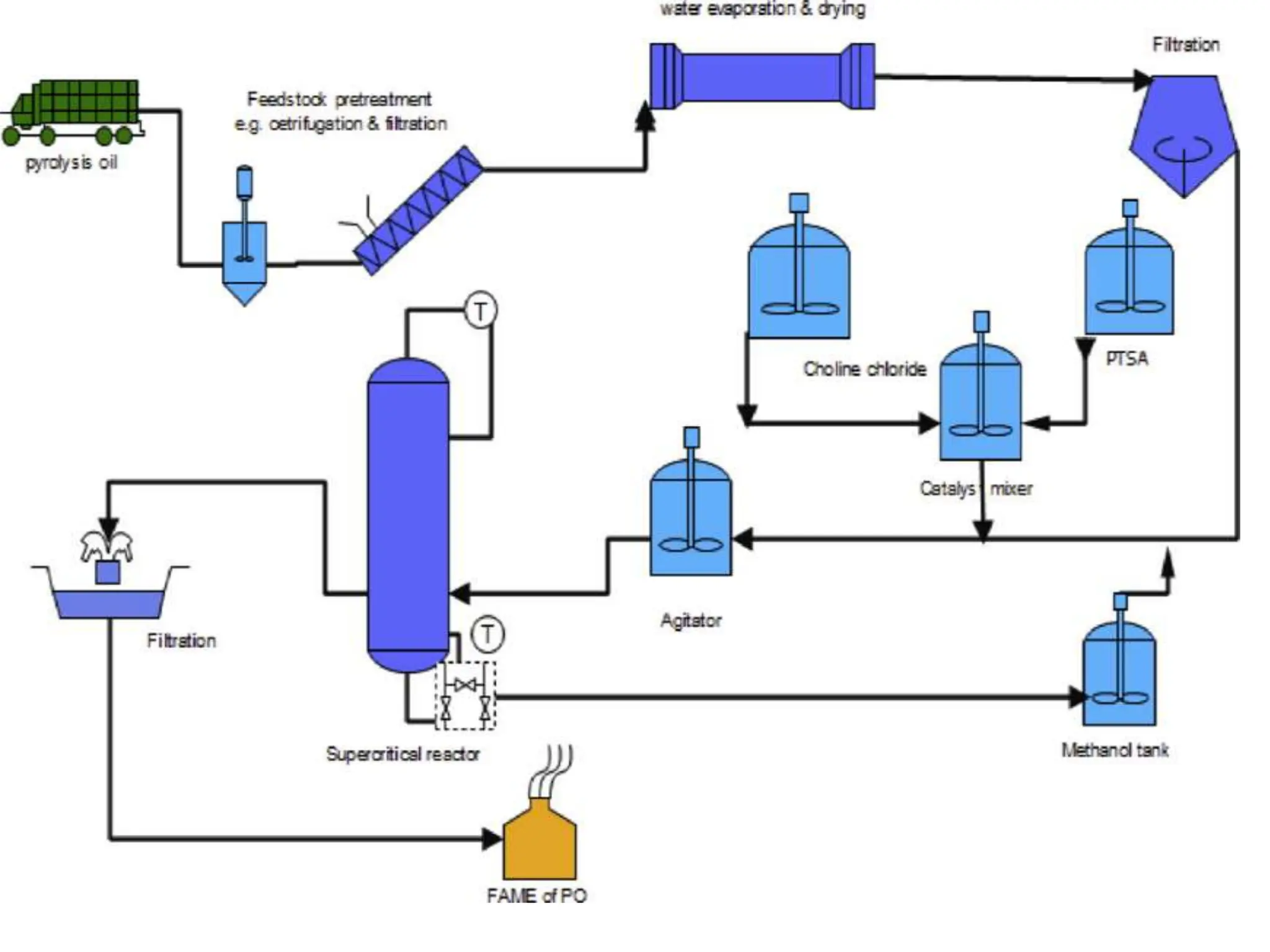

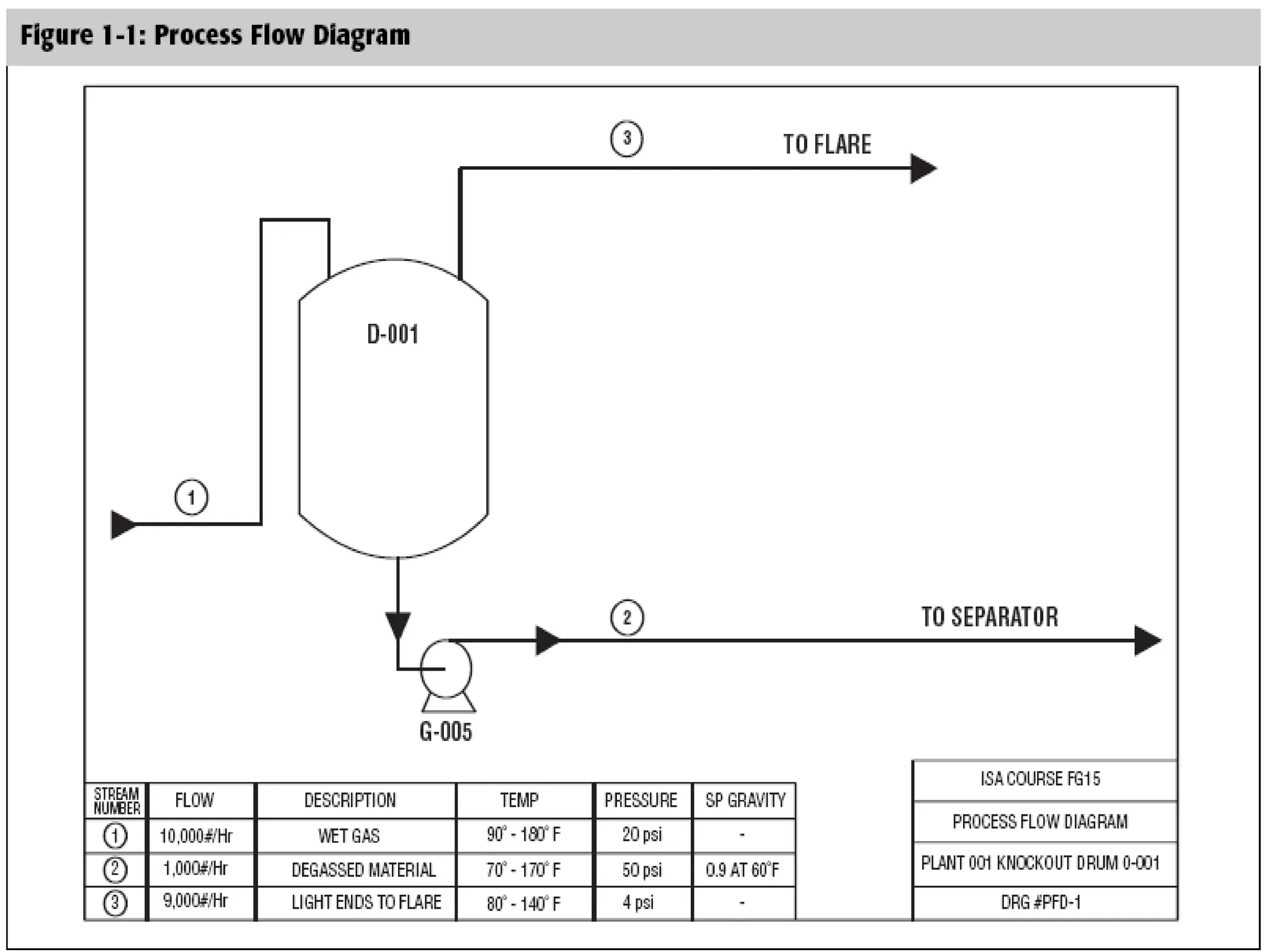

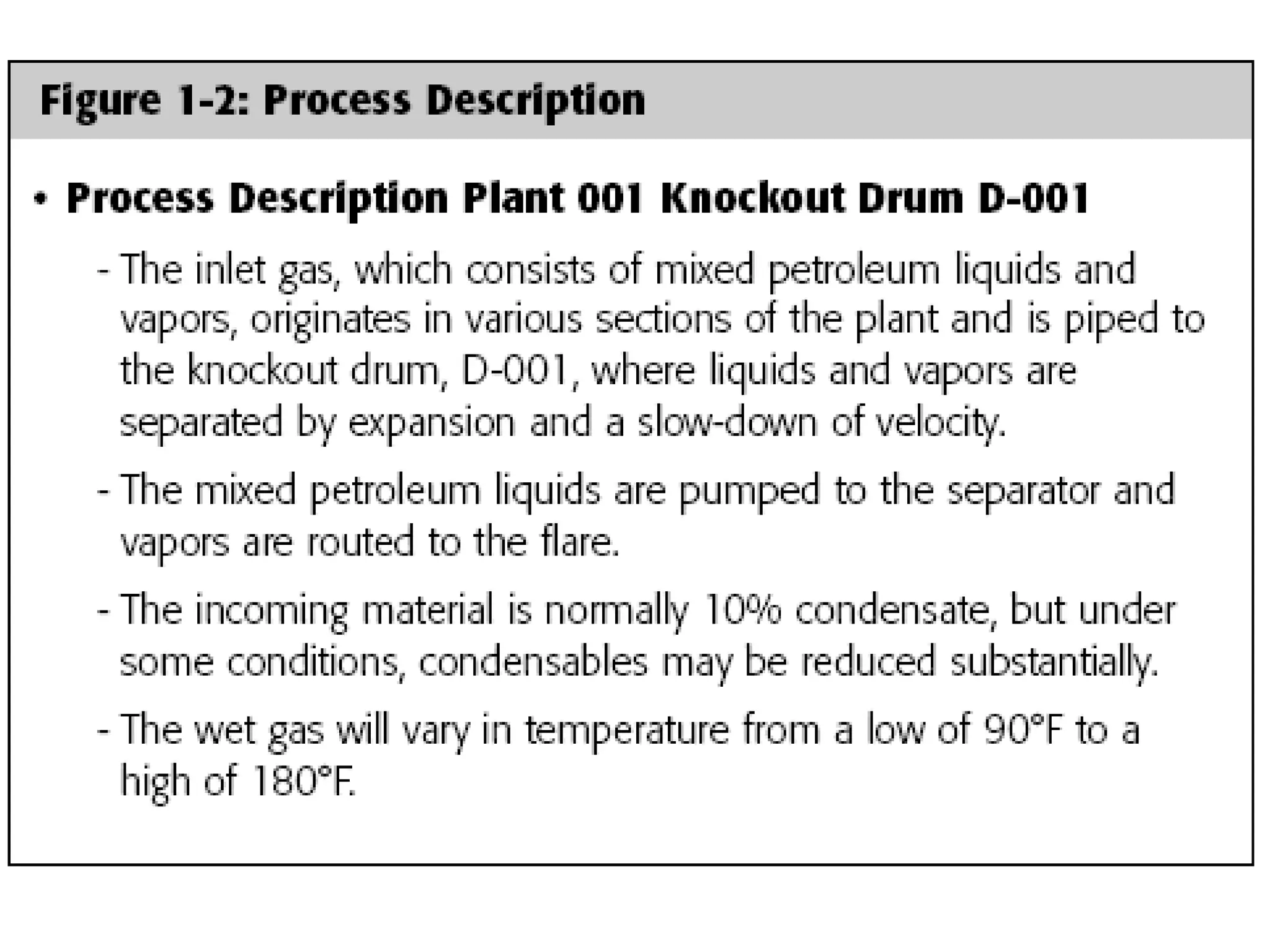

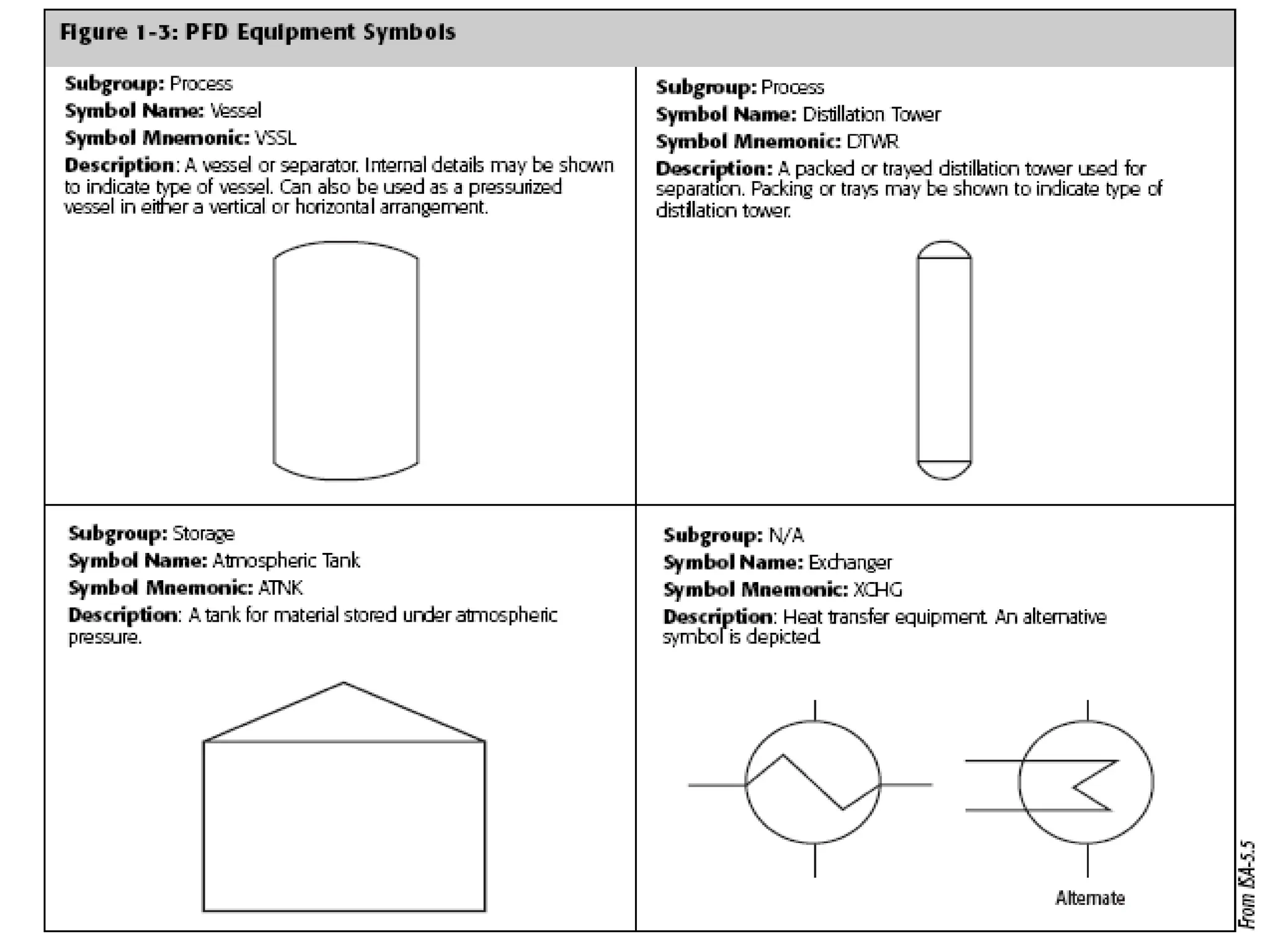

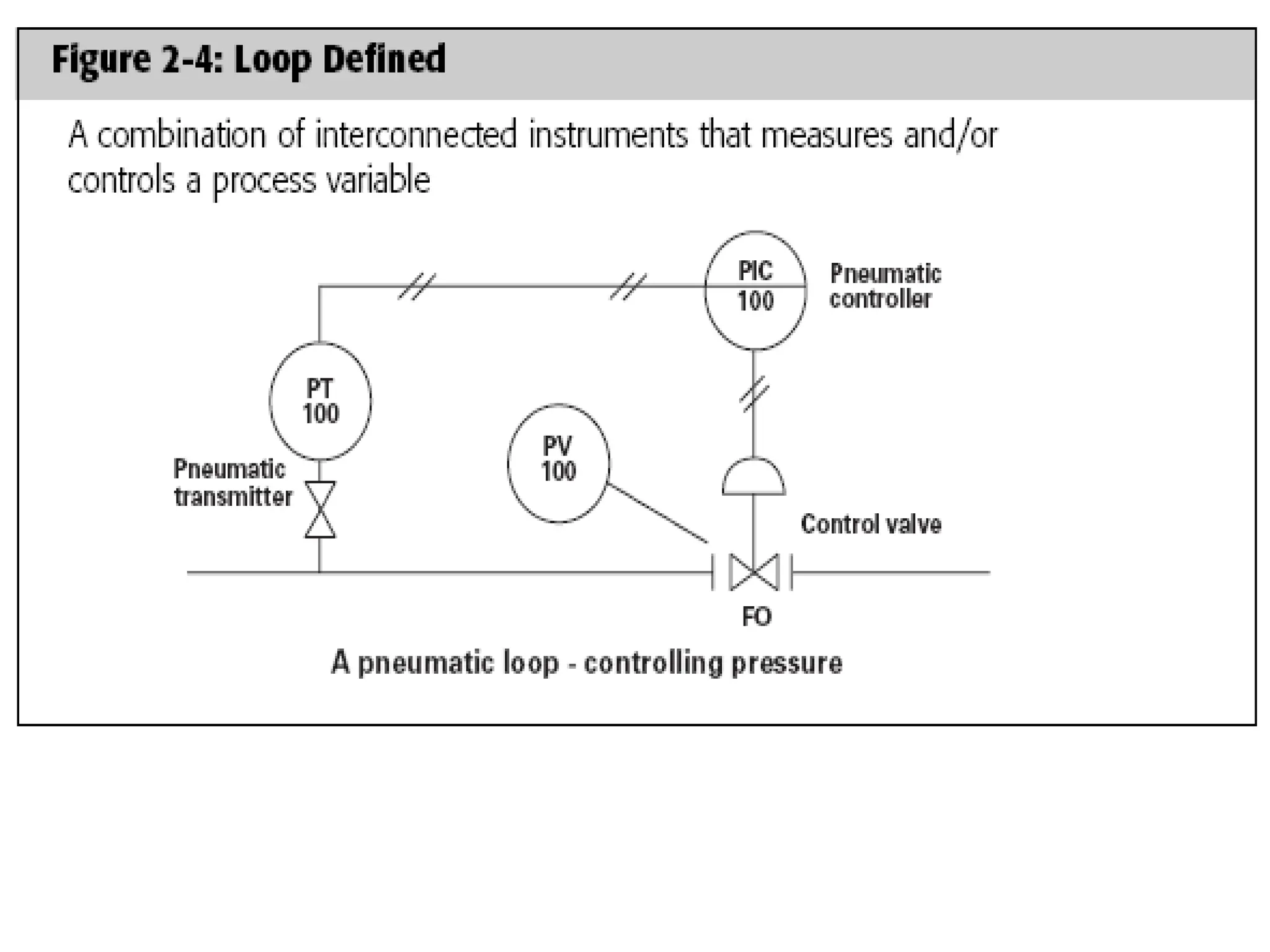

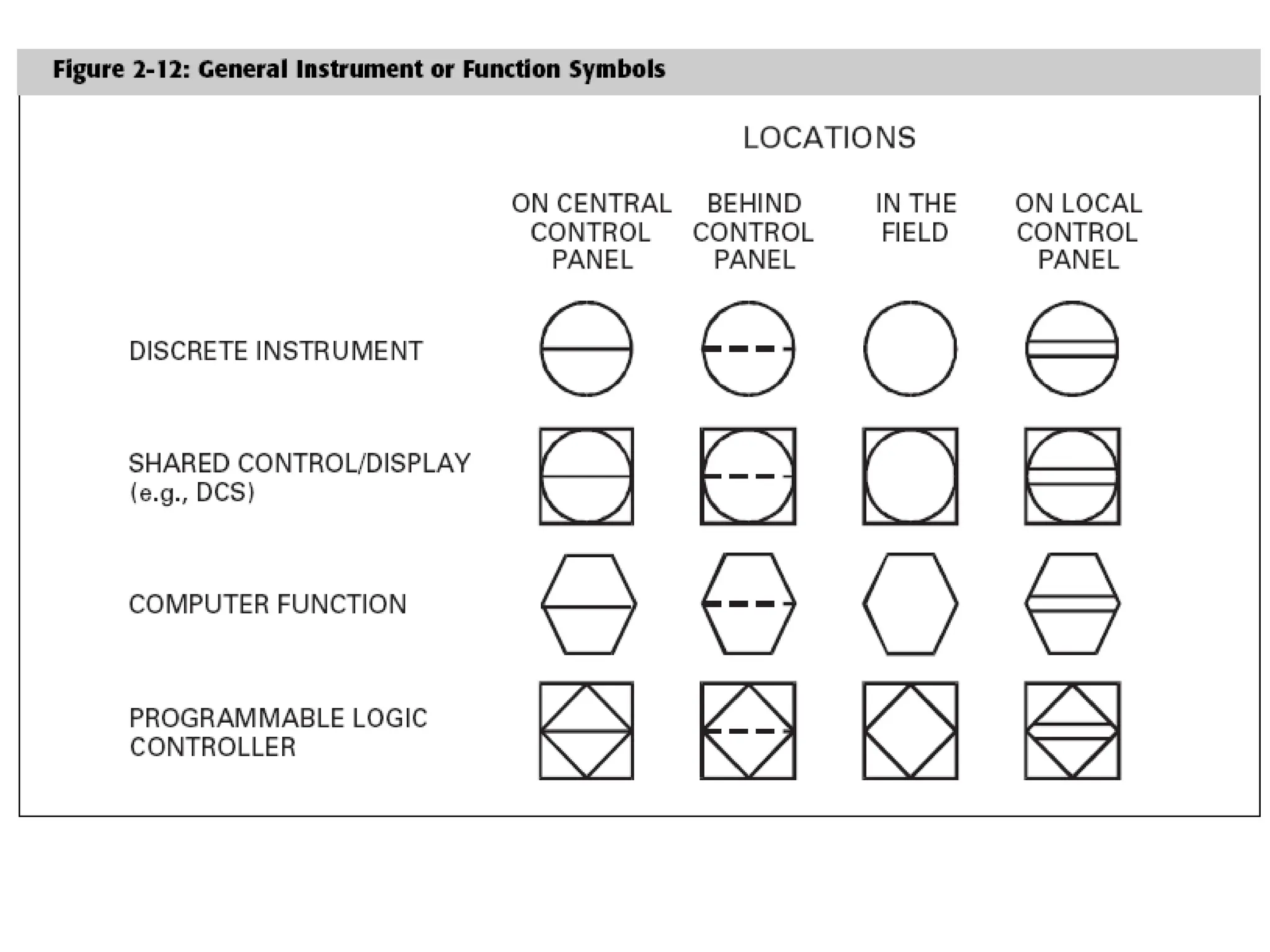

The document discusses process flow diagrams (PFDs) and process and instrumentation diagrams (P&IDs), which are diagrams used in chemical and process engineering. A PFD shows the major equipment and flow of materials in a process at a high level, while a P&ID includes more detailed information on instrumentation and piping. Both diagrams are developed iteratively and include defined sets of symbols to represent process components and are used across engineering disciplines in designing and understanding processes.