BASF provides concise summaries of 3 sentences or less:

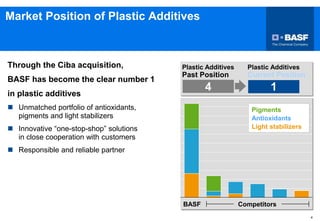

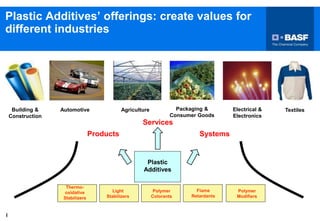

BASF is a global leader in plastic additives and offers a wide range of products to protect packaging from UV light and visible light degradation. Their portfolio includes light stabilizers, antioxidants, effect pigments and dyes, and other additives that can improve the durability and quality of packaged goods. BASF works closely with customers in the packaging industry to develop innovative and customized solutions that meet performance and regulatory requirements.

![02 06.2011 15

Protection of sunflower oil

Film with UV absorber

0.00

20.00

40.00

60.00

80.00

100.00

120.00

140.00

160.00

0.00 5.00 10.00 15.00 20.00 25.00 30.00 35.00 40.00 45.00 50.00

time [d]

consumption

of

oxygen

[mg]

Film with no UV protection

Study run at the Fraunhofer IVV

Extension of the shelf life by 95%

95% Extended Shelf Life](https://image.slidesharecdn.com/additivesforplasticpackaging-240402055931-bf9e66b9/85/Additives-forthe-Plastic-Packaging-pptx-15-320.jpg)