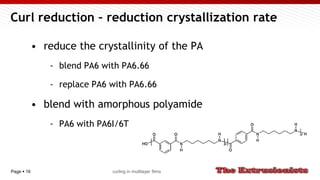

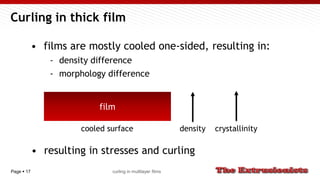

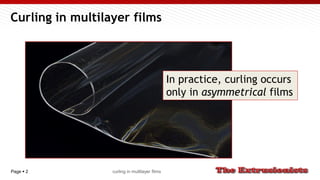

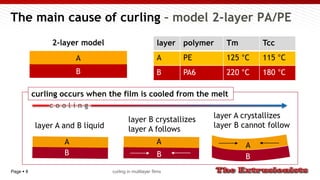

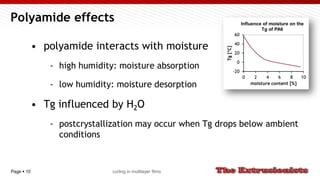

The document discusses curling in multilayer films, focusing on the challenges presented by asymmetrical films composed of different polymers. It outlines the causes of curling, such as variations in melting points and crystallization rates, and presents potential remedies including the use of water baths and film annealing. The advantages and disadvantages of these films are also discussed, along with conclusions on reducing curling effects.

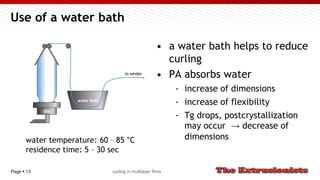

![Page 14

Curl reduction - water bath

0

50

100

150

200

250

1 2 3

curlfactor[m-1]

Reeks1

Reeks2

Reeks3

• residence time in water bath 5 sec

• 3-layer blown film of 100 μm

curling in multilayer films](https://image.slidesharecdn.com/curlinginmultilayerfilms-161208154220/85/Curling-in-multilayer-films-14-320.jpg)