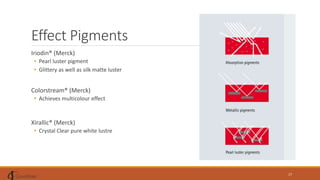

This document discusses masterbatch, which is polymer granules containing a high percentage of additives that are optimally dispersed and encapsulated in a carrier material. There are three main types of masterbatch: color masterbatch for coloring plastics, additive masterbatch for imparting certain properties, and filler masterbatch for cost reduction. The goal of masterbatch production is ideal dispersion and distribution of pigments or additives in the polymer matrix without agglomeration. This can be achieved through single or two-stage production processes using an extruder to mix and disperse the components. The document provides examples of effect pigments, common additive types, and fillers that are used in masterbatch production.