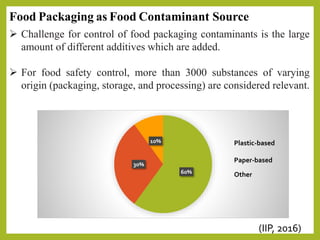

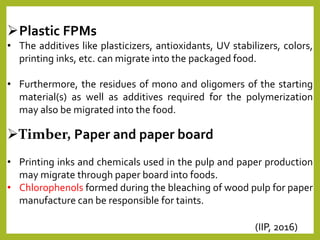

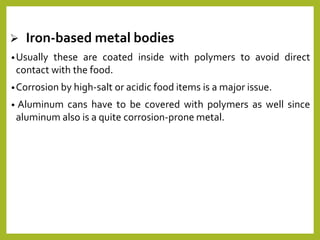

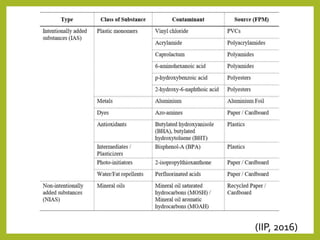

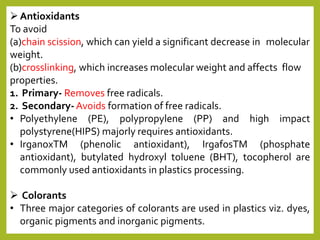

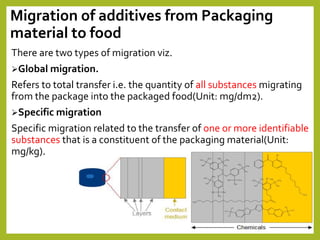

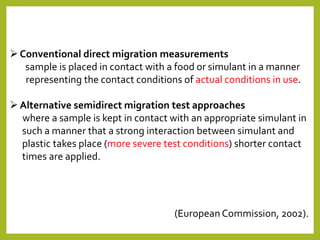

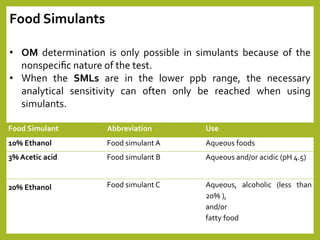

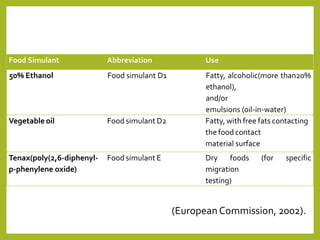

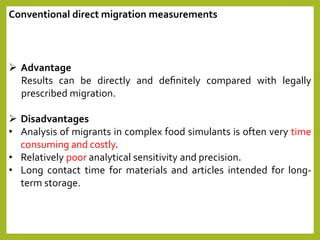

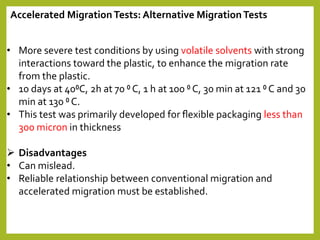

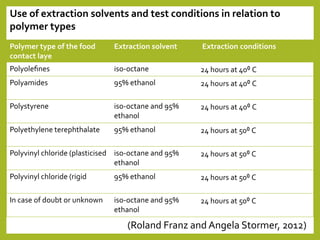

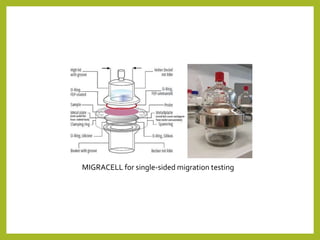

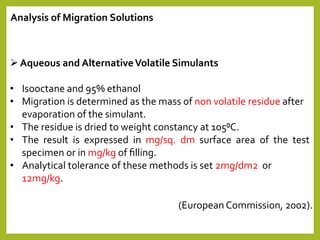

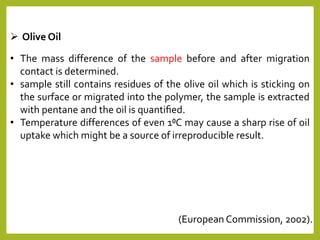

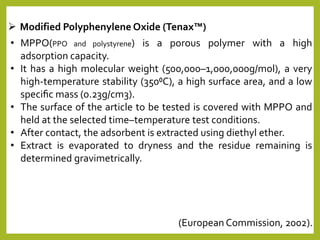

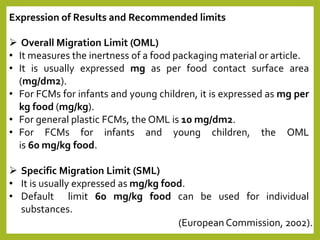

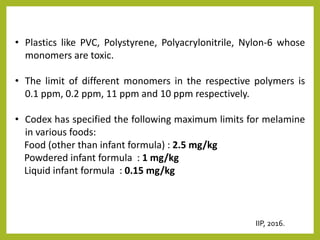

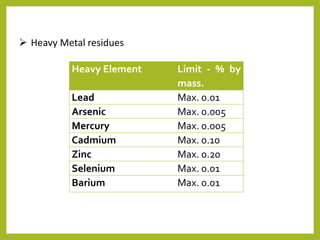

The document discusses the safety aspects of food packaging materials and their potential as sources of chemical contaminants in food, emphasizing the migration of additives from packaging to food. Various factors influence migration, such as the chemical properties of both the packaging and the food, as well as temperature and contact duration. Recommended limits for overall migration and specific migration are outlined, with a focus on the importance of testing and regulatory compliance to ensure food safety.