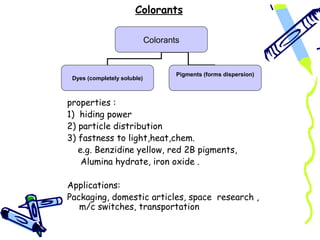

Additives are materials that are added to polymers to impart desirable properties without significantly altering the polymer's molecular structure. They are used to improve processing, increase stability and resistance, and control properties like hardness, surface tension, color, and flame resistance. Common types of additives include fillers, antioxidants, heat stabilizers, UV stabilizers, colorants, antistatics, flame retardants, cross-linking agents, blowing agents, lubricants, and impact modifiers. Additives are important for attaining properties required for various applications, especially in packaging where they can enhance barrier properties, transparency, printability, and antimicrobial effects.