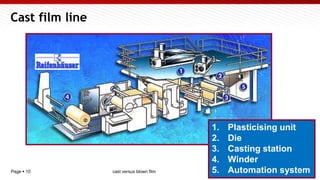

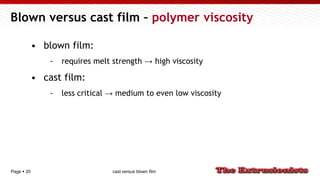

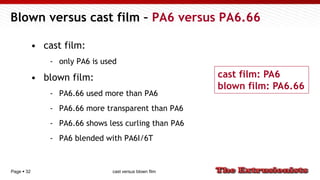

This document compares cast and blown film production technologies for polyamide films. Cast film uses a chill roll for efficient cooling, resulting in faster cooling rates that produce films with lower crystallinity, higher transparency, and better thermoforming performance compared to blown film. Blown film uses air cooling, which is less efficient than the chill roll, leading to slower cooling rates and more crystallinity. However, blown film requires less floor space and investment. Both technologies can produce similar applications, but cast film is generally better for properties requiring fast cooling while blown film has lower costs.

![Page 6

Polyamide properties

PA-type

Melting point

[°C]

H2O permeability

[cc/m2/atm/day]

O2 permeability

[cc/m2/atm/day]

PA66 255 8 12

PA6 220 15 12

PA6.12 215 5 45

PA6.66 195 16 14

PA11 190 4 120

PA12 180 5 190

cast versus blown film](https://image.slidesharecdn.com/castversusblownfilm-160815160537/85/Cast-versus-blown-film-6-320.jpg)