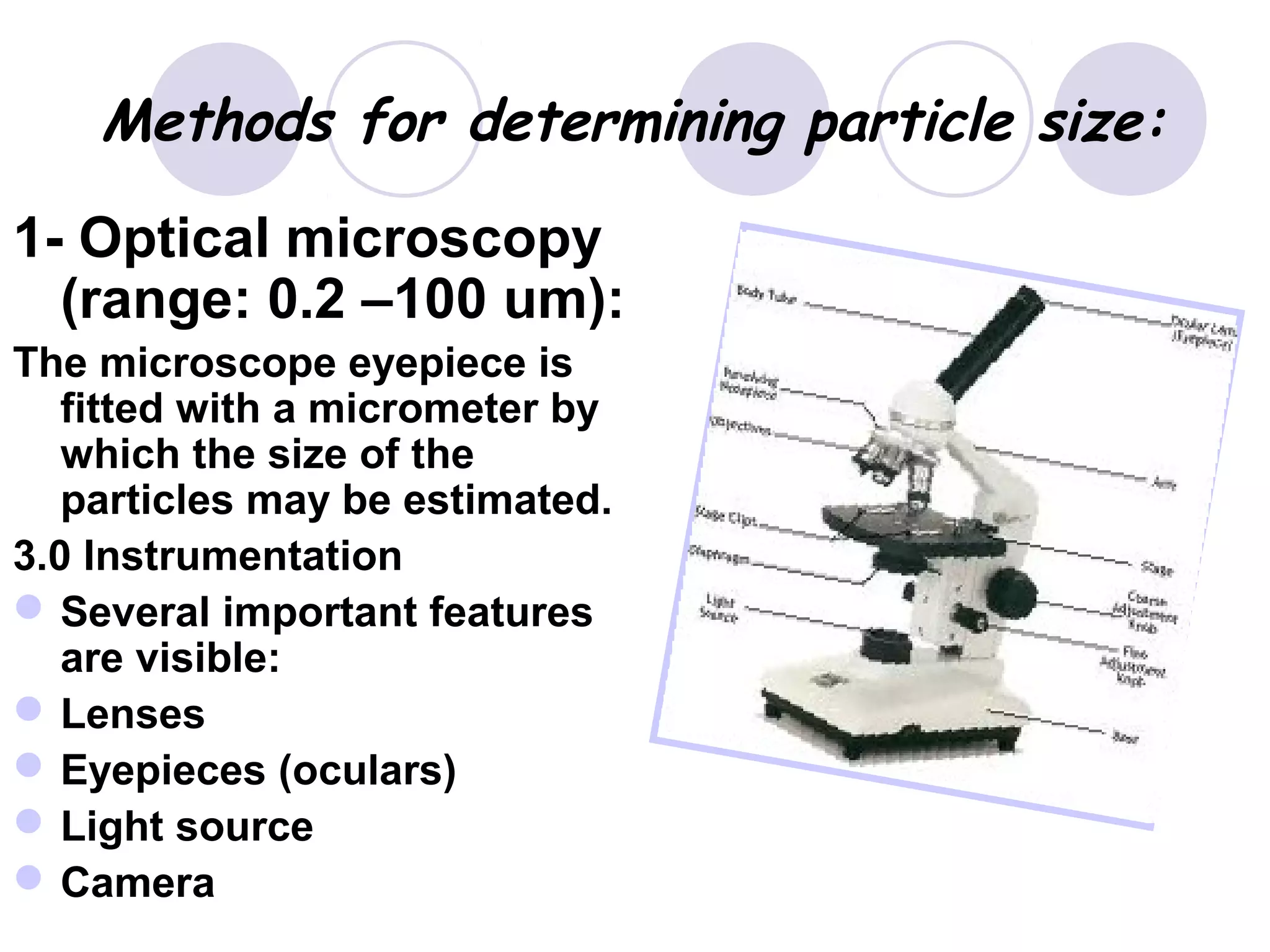

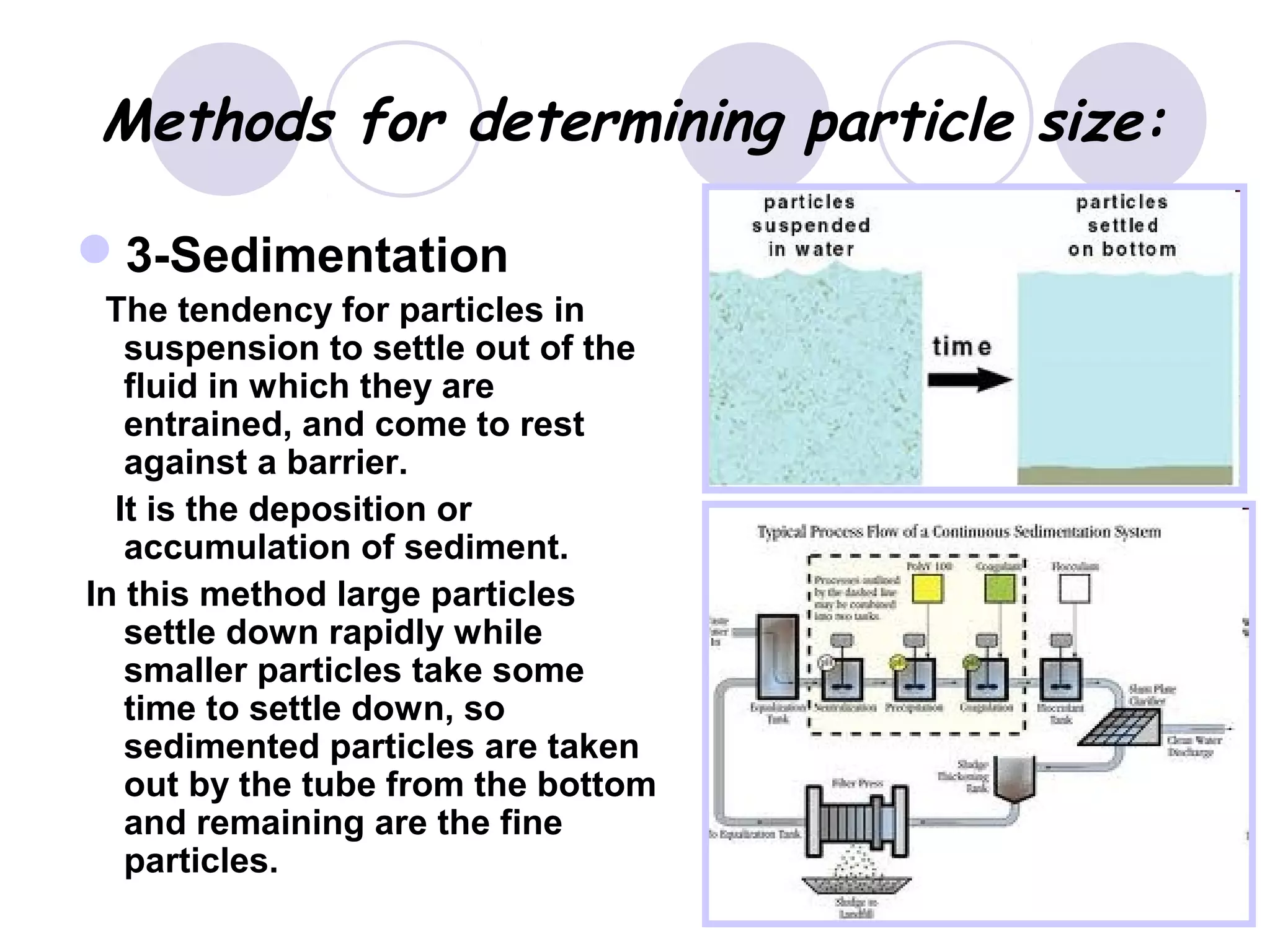

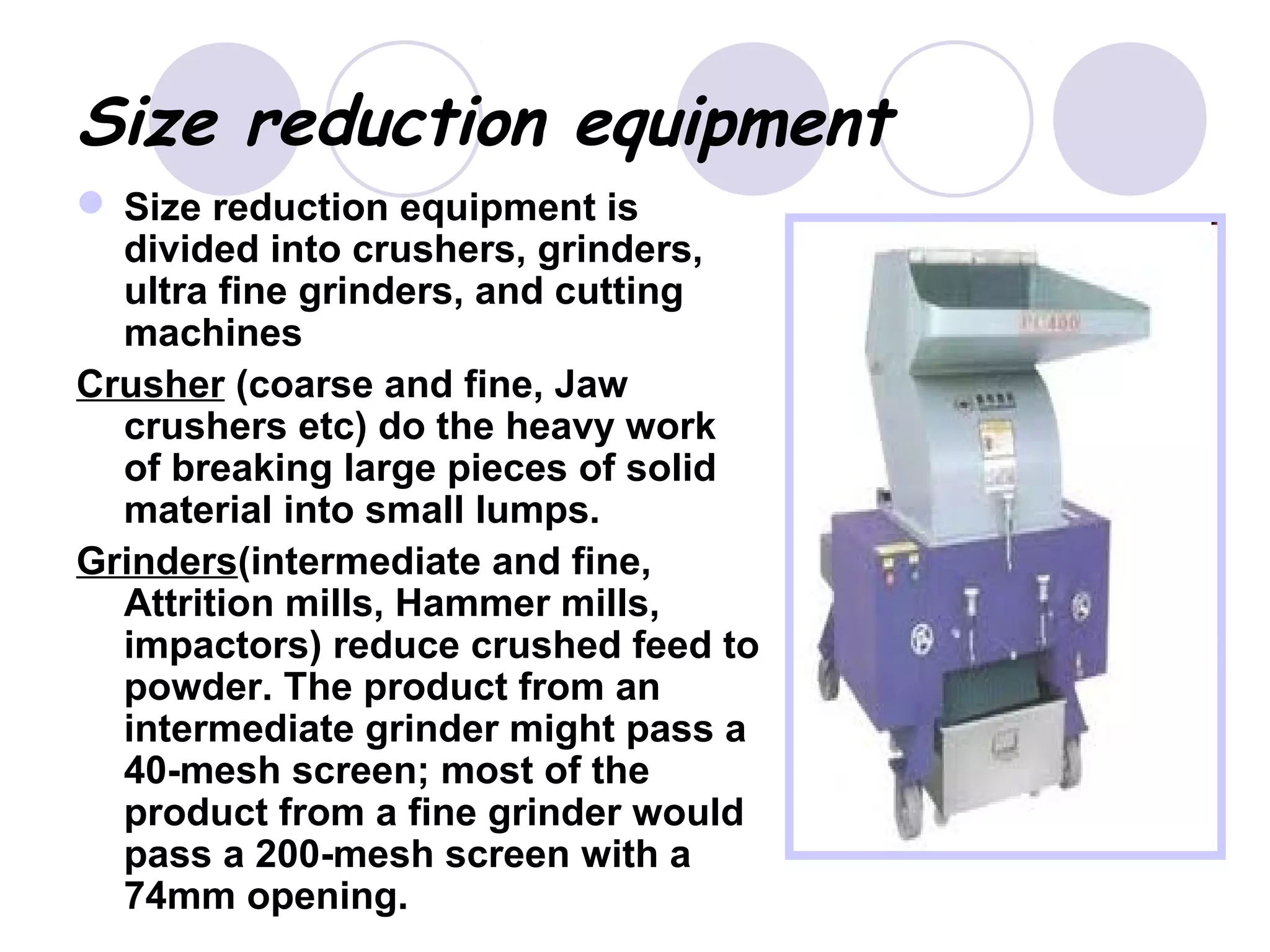

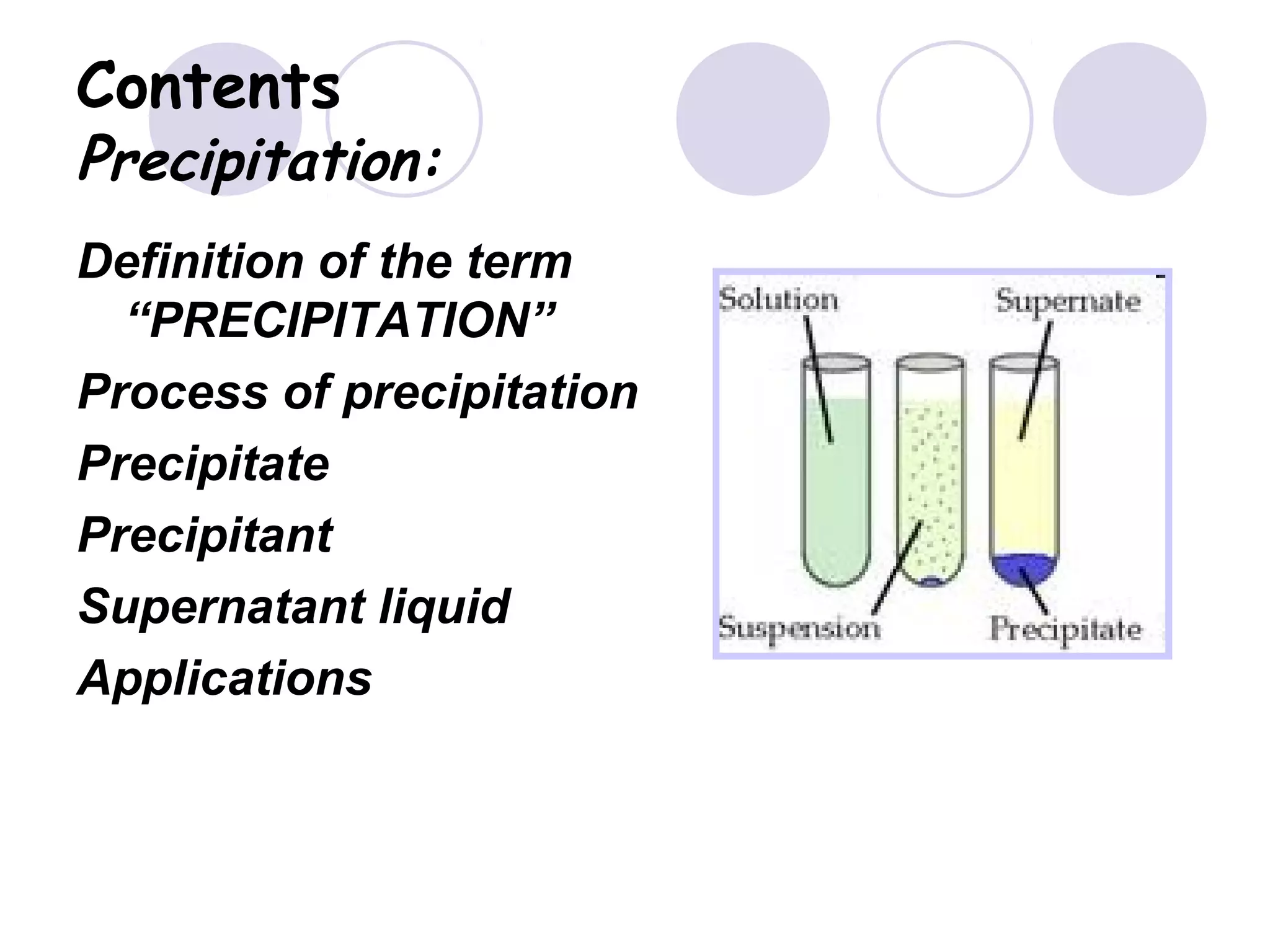

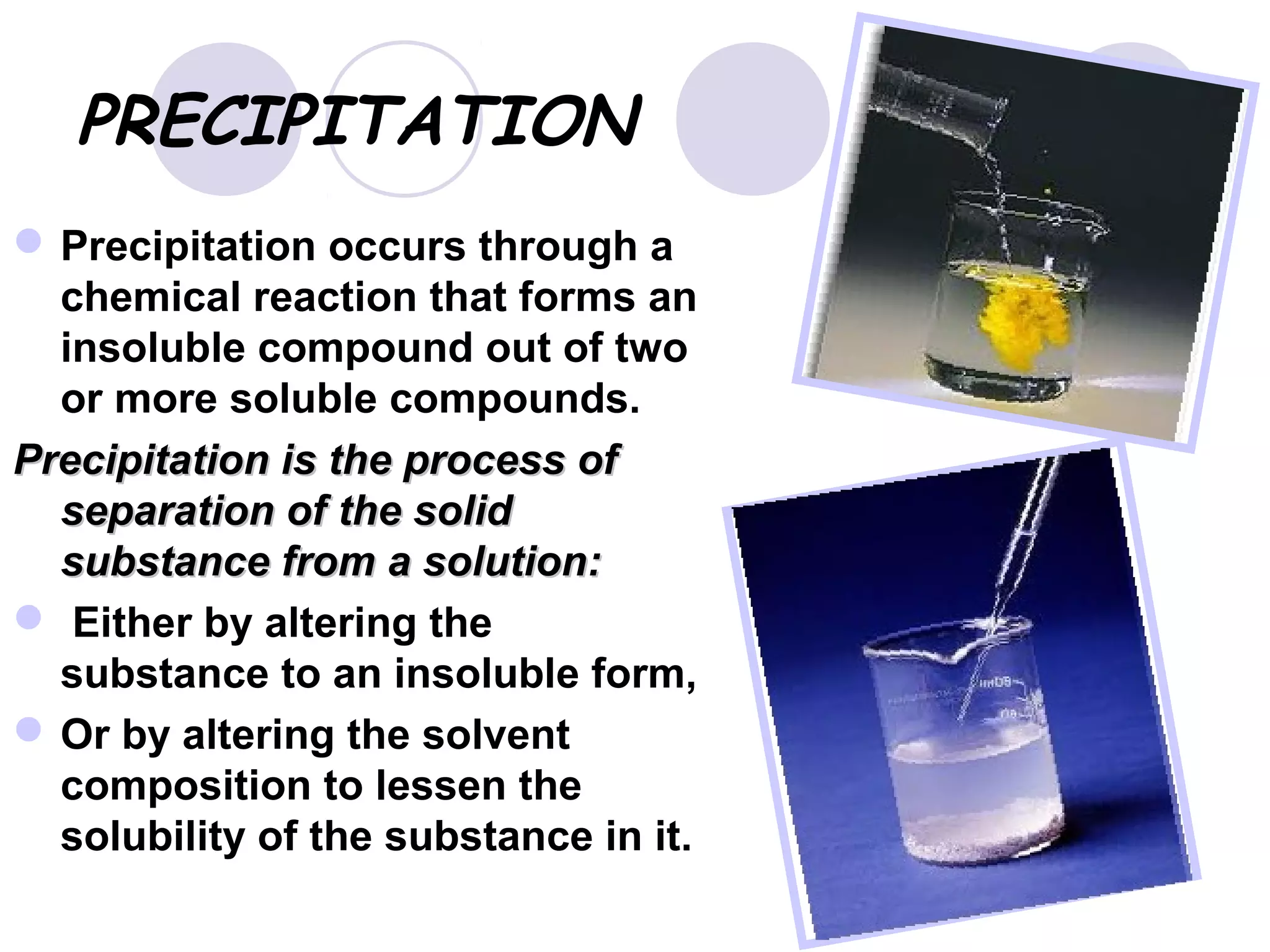

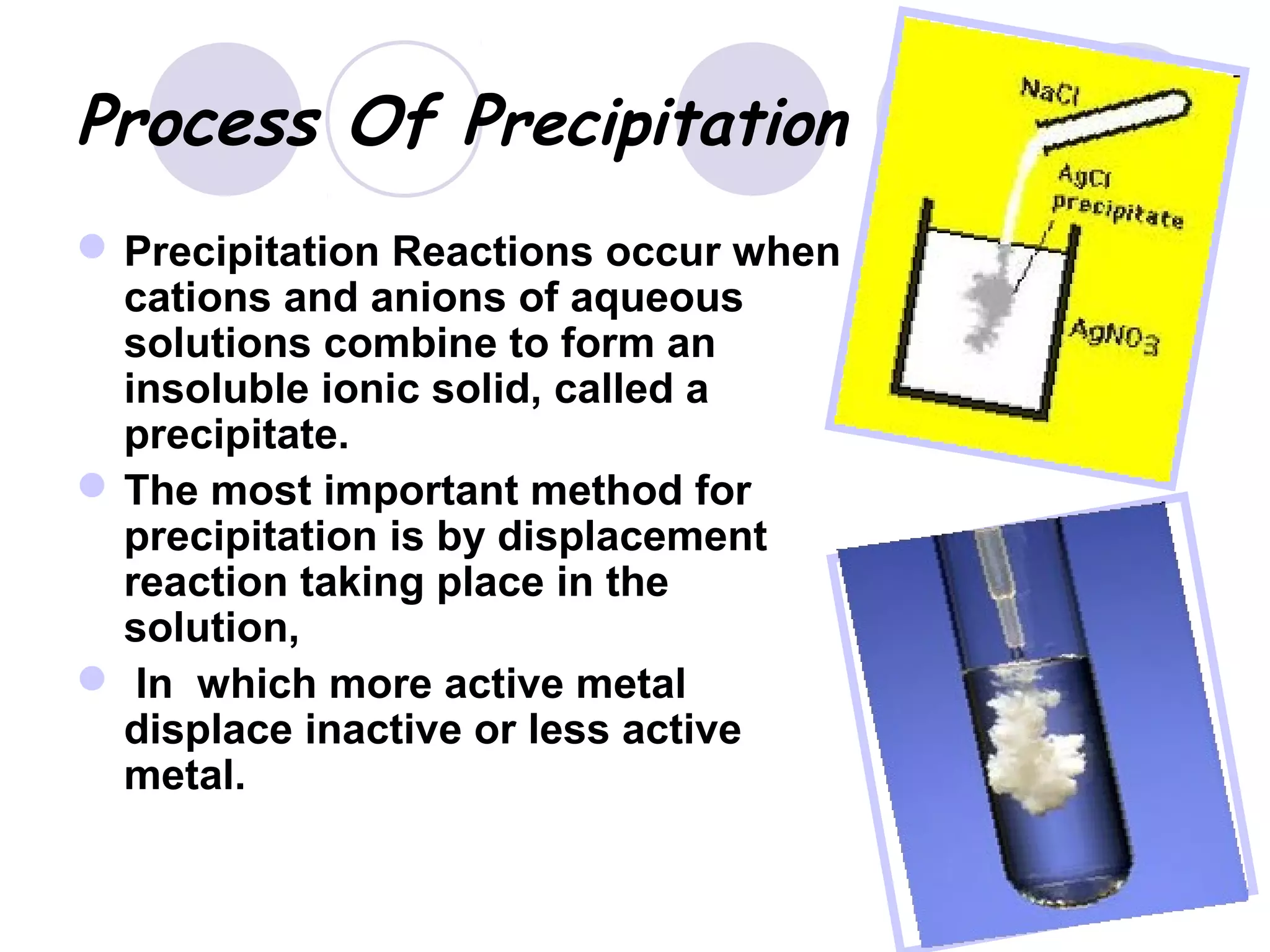

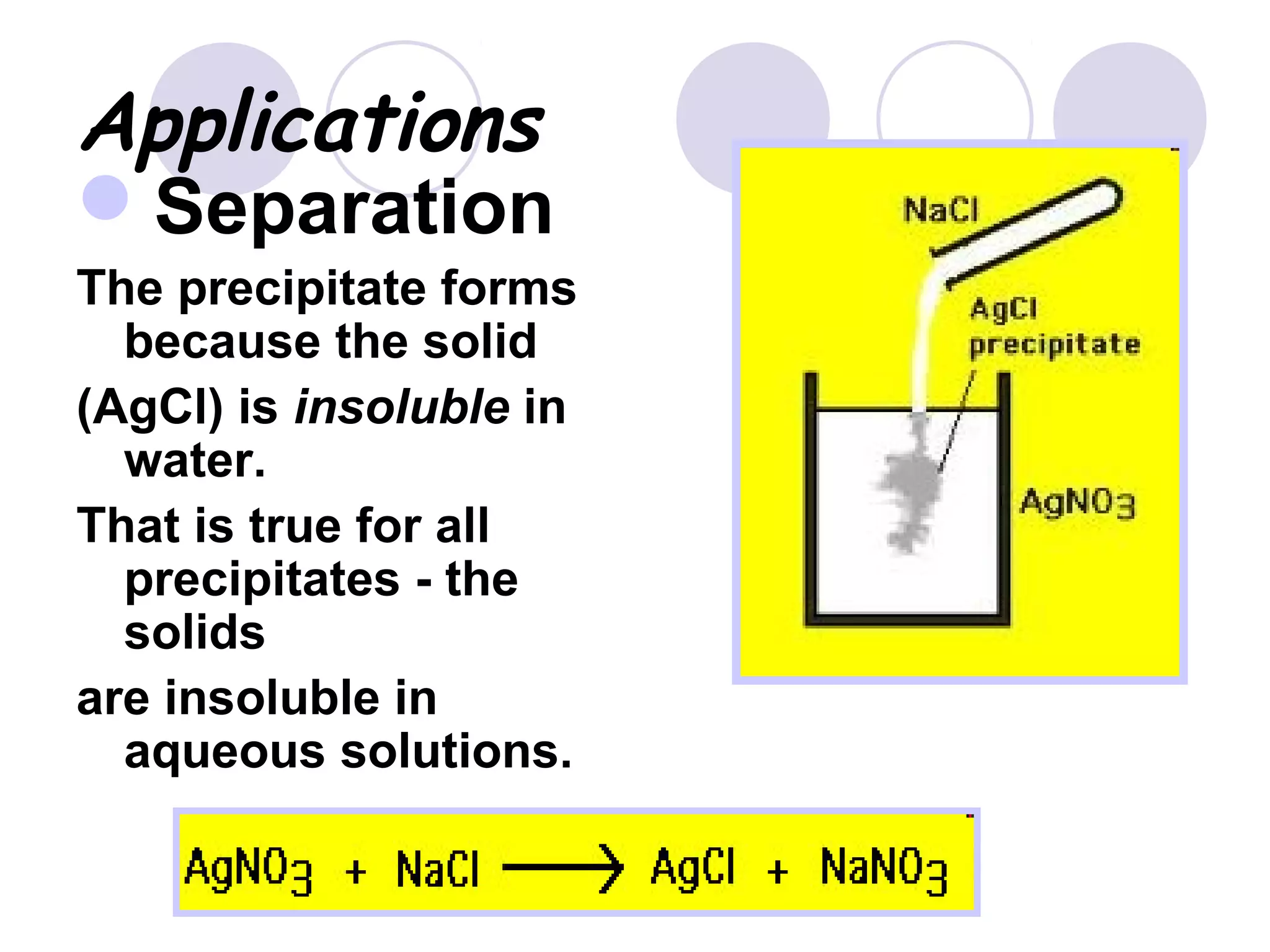

The document provides detailed information on micromeritics and precipitation, emphasizing the importance of particle size in pharmaceutical applications. Topics include factors affecting powder flow properties, methods for particle size analysis, and the processes and applications of precipitation in separating and purifying substances. Additionally, it outlines various methods for size reduction, true density, and porosity, linking these properties to drug stability and absorption.