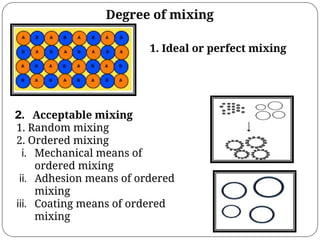

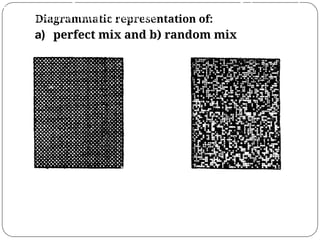

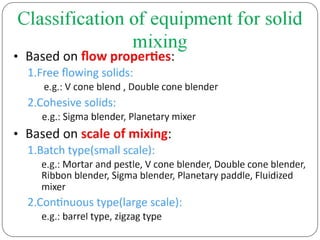

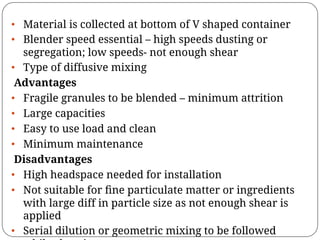

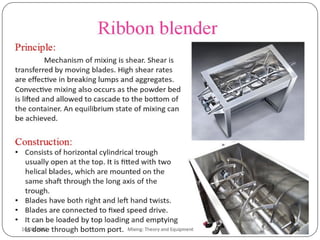

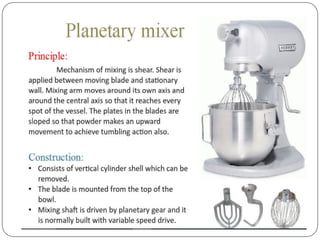

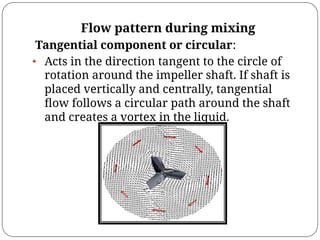

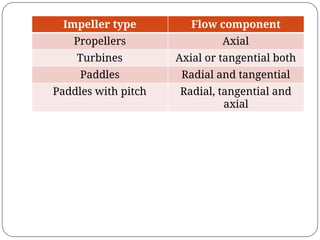

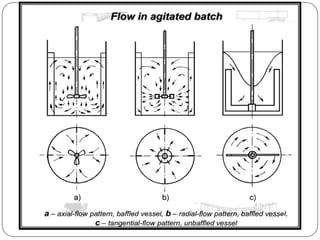

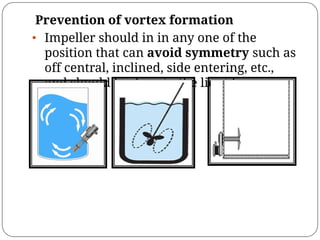

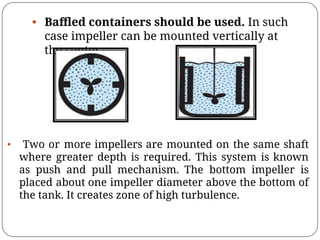

This document discusses mixing in pharmaceutical applications. It defines mixing as putting together components so that particles are in contact with each other. The objectives of mixing are to achieve uniform composition and promote reactions. Mixing is used in processes like granulation, direct compression, and capsule filling. Factors like particle properties, proportions, and equipment used can affect mixing. The mechanisms of solid, liquid, and semisolid mixing are explained. Different mixing equipment and their workings are also presented.