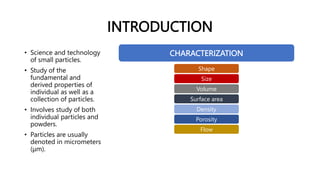

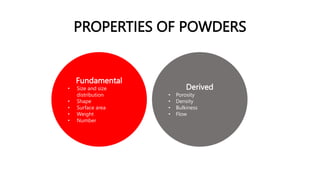

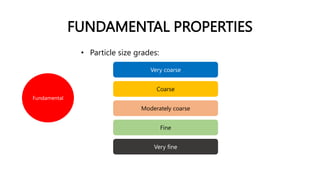

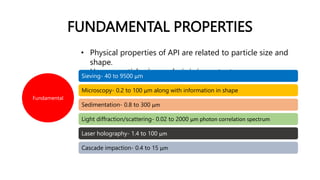

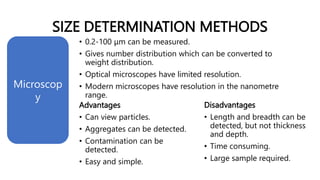

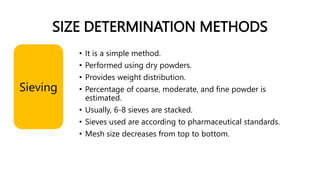

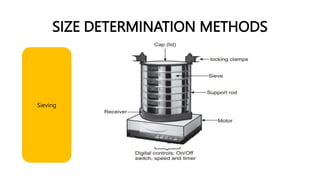

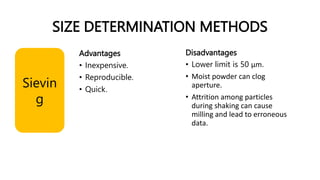

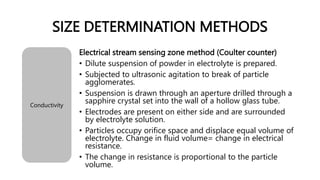

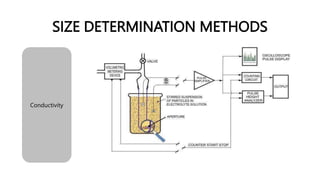

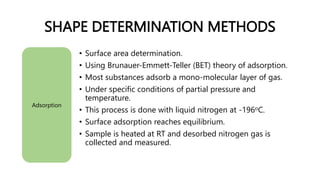

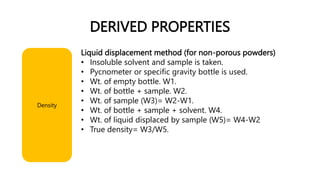

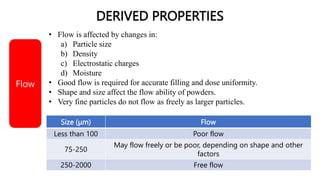

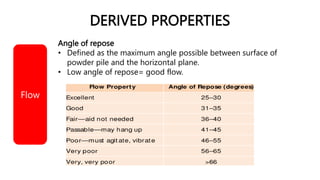

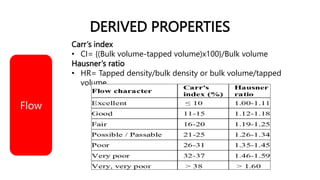

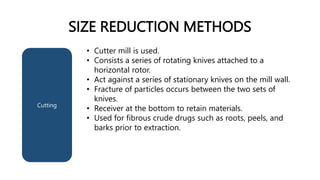

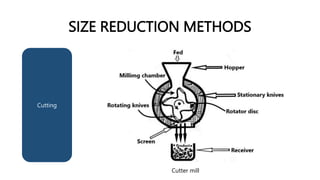

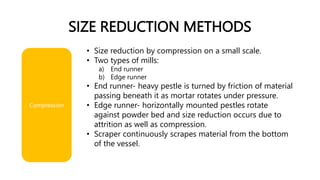

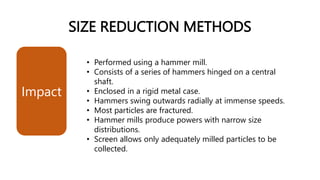

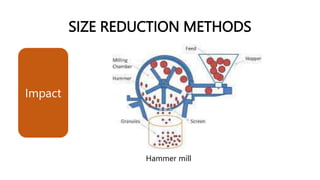

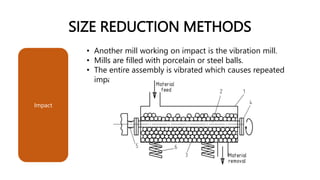

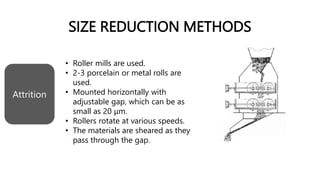

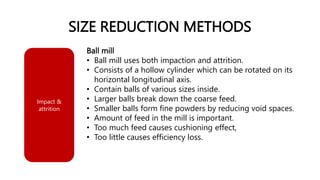

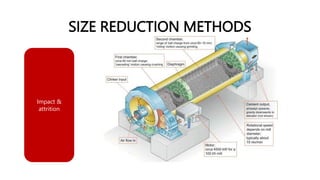

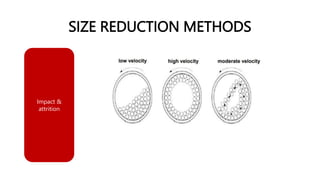

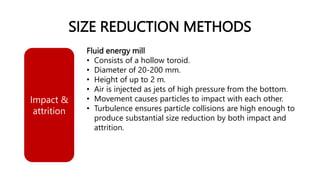

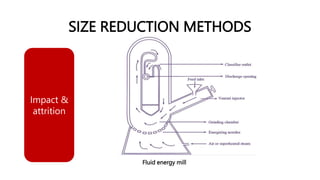

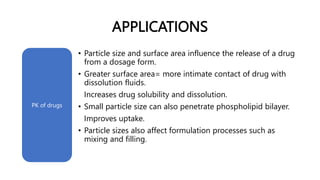

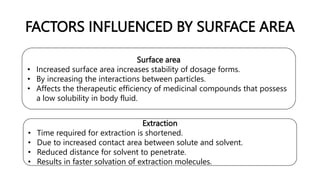

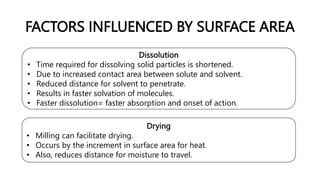

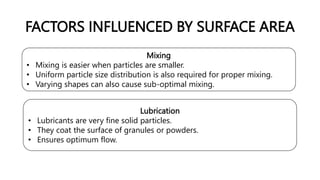

The document discusses the science and technology of micromeritics, focusing on the properties, characterization, and methods for determining the size, shape, and distribution of particles and powders, which are crucial in pharmaceutical applications. It covers size determination techniques, the effects of particle properties on drug formulation and stability, and various size reduction methods. Key derived properties such as porosity and flow are also examined, emphasizing their impact on drug absorption and therapeutic action.