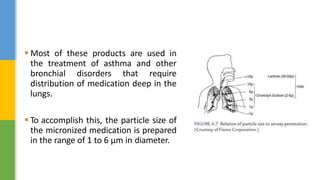

This document discusses powders used in pharmaceutical preparations. Powders are mixtures of finely divided drugs and chemicals that can be used internally or externally. Powders are characterized based on properties like particle size, morphology, purity, solubility, and stability. Powder particle size ranges from 10 mm to 1 μm. Powders are analyzed using sieving, sedimentation rate, microscopy, and other methods. Proper particle size influences dissolution, suspension, distribution in mixtures, and other factors. Segregation during blending can be an issue and is influenced by particle size, shape, density, and other properties. Powders are used to prepare various dosage forms like tablets, capsules, liquids, and semisolids through processes like blending,

![• Bulk Powders

Among the bulk powders available in prepackaged amounts are:

a. Antacids (e.g., sodium bicarbonate) and laxatives (e.g., psyllium [Metamucil]),

which the patient takes by mixing with water or another beverages before

swallowing

b. Douche powders: dissolved in warm water by the patient for vaginal use

c. Medicated powders for external application to the skin, usually topical

antiinfectives (e.g., bacitracin zinc and polymyxin B sulfate) or antifungals (e.g.,

tolnaftate)

d. Brewer’s yeast powder containing B-complex vitamins and other nutritional

supplements.

In some cases, a small measuring scoop, spoon, or other device is dispensed with the

powder for measuring the dose of the drug.](https://image.slidesharecdn.com/powder1-240228061643-f7a87a82/85/solid-dosage-forms-powders-pharmaceutical-technology-62-320.jpg)