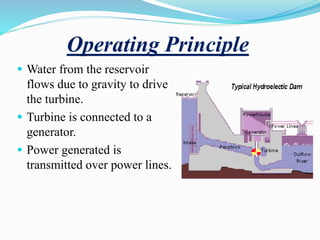

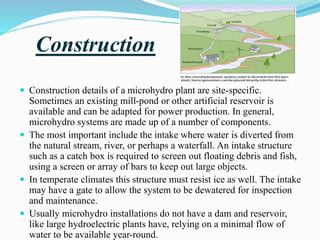

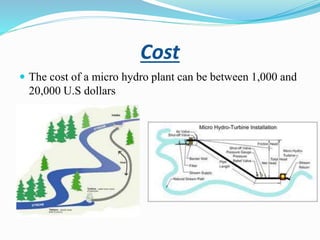

Micro hydel power plants generate up to 100 kW of electricity by utilizing the natural flow of water, making them suitable for isolated homes or small communities, especially in developing nations. The construction of these systems is site-specific and involves components like intake structures and turbines, with various types such as impulse and reaction turbines available based on head and flow conditions. While they offer a low-cost and environmentally friendly energy solution, their effectiveness is constrained by site characteristics and distance from power usage locations.