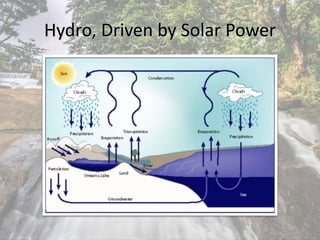

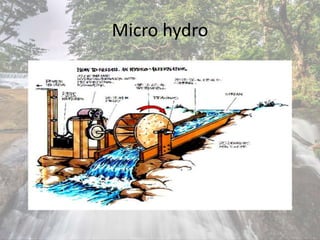

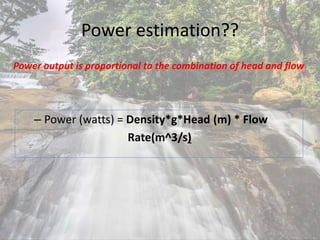

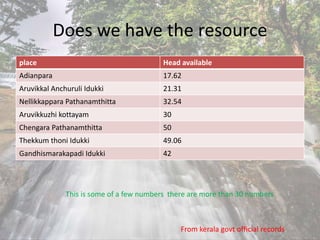

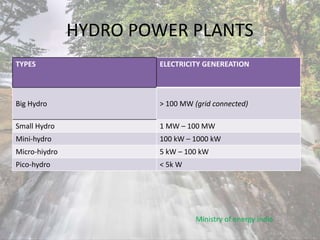

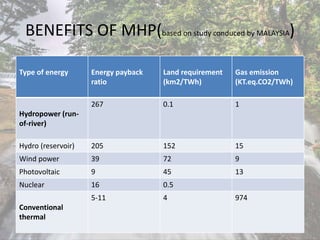

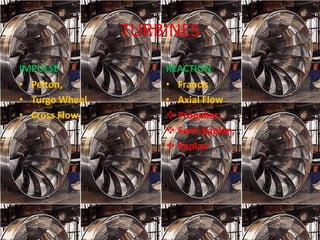

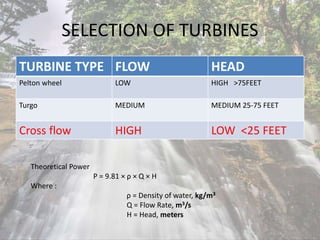

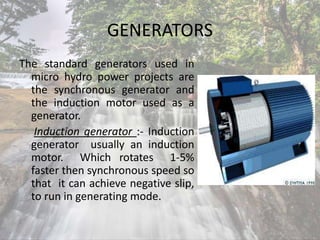

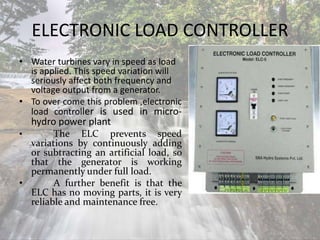

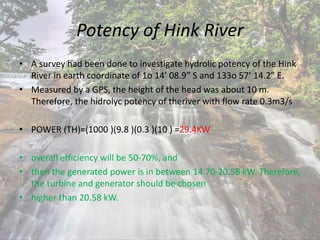

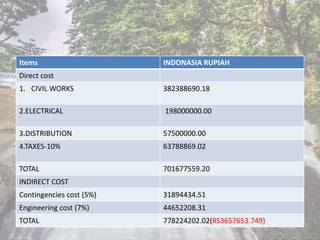

This document summarizes the key aspects of micro hydro electric projects for rural electrification. It discusses that micro hydro projects have minimal environmental impact and can operate continuously using small amounts of flowing water without needing a large dam. The document provides examples of suitable head heights available in various locations in Kerala. It also outlines the components, design considerations, power estimations, and cost analysis of typical micro hydro projects. In conclusion, it states that micro hydro is a feasible solution to provide power to remote areas and many government policies support their development.