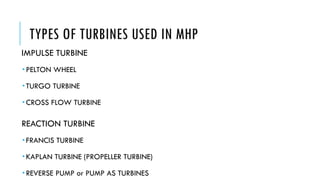

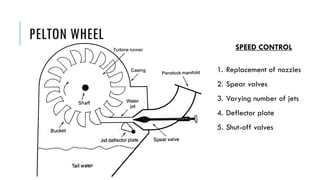

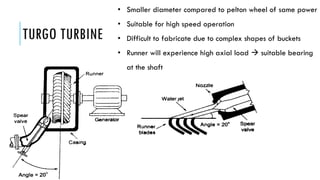

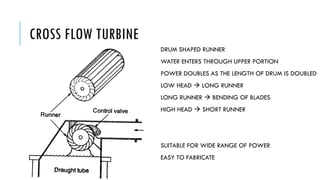

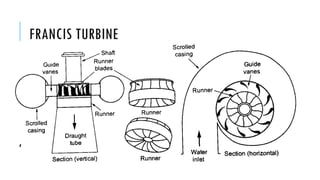

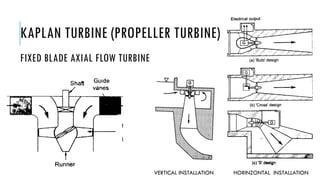

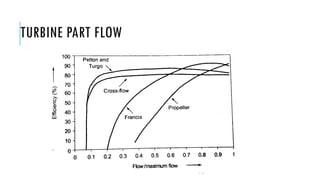

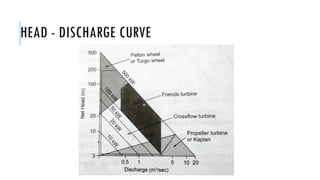

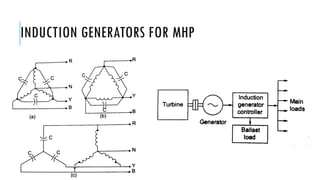

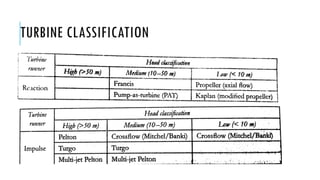

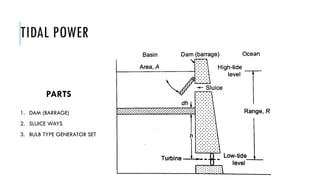

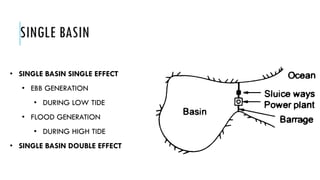

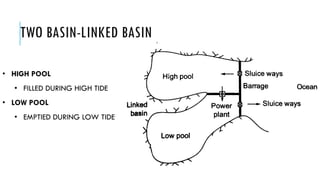

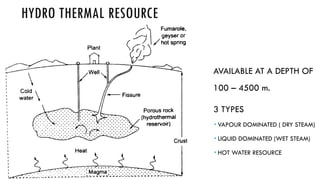

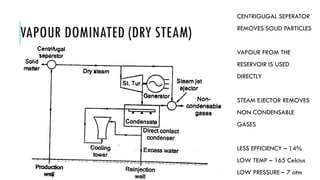

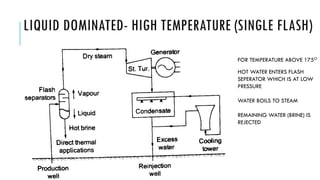

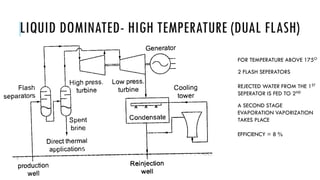

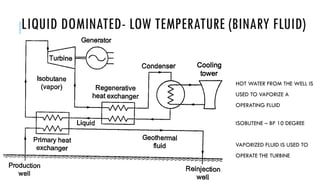

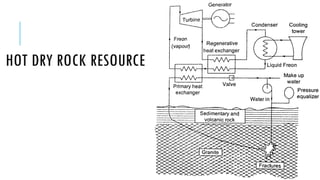

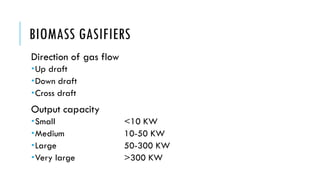

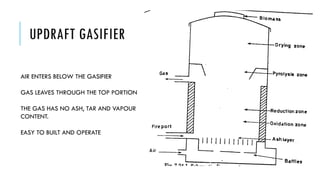

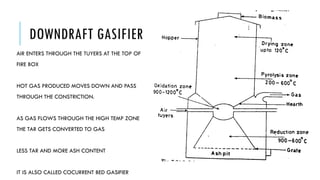

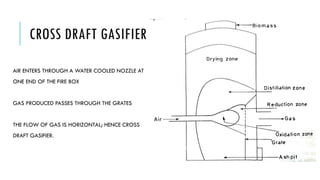

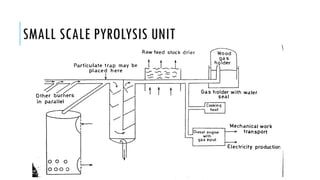

The document discusses various renewable energy sources, including micro hydel, geothermal, tidal power, and biomass gasifiers, detailing types of turbines used in micro hydel systems, such as impulse and reaction turbines. It outlines the operation of tidal power systems and explains geothermal energy types, including hydrothermal and hot dry rock resources. Additionally, it describes biomass gasifier designs and their output capacities, enumerating the advantages and characteristics of different gasification methods.