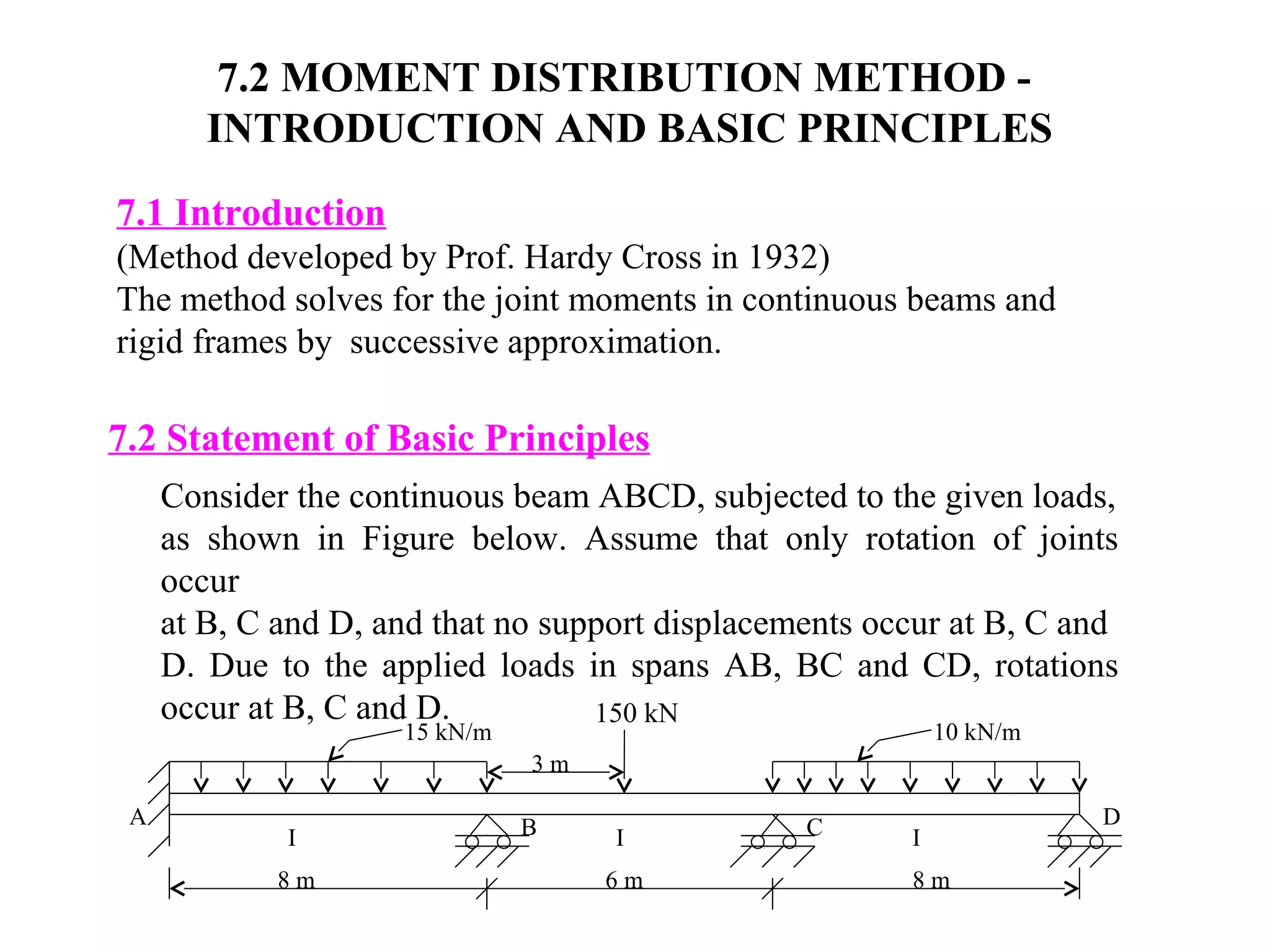

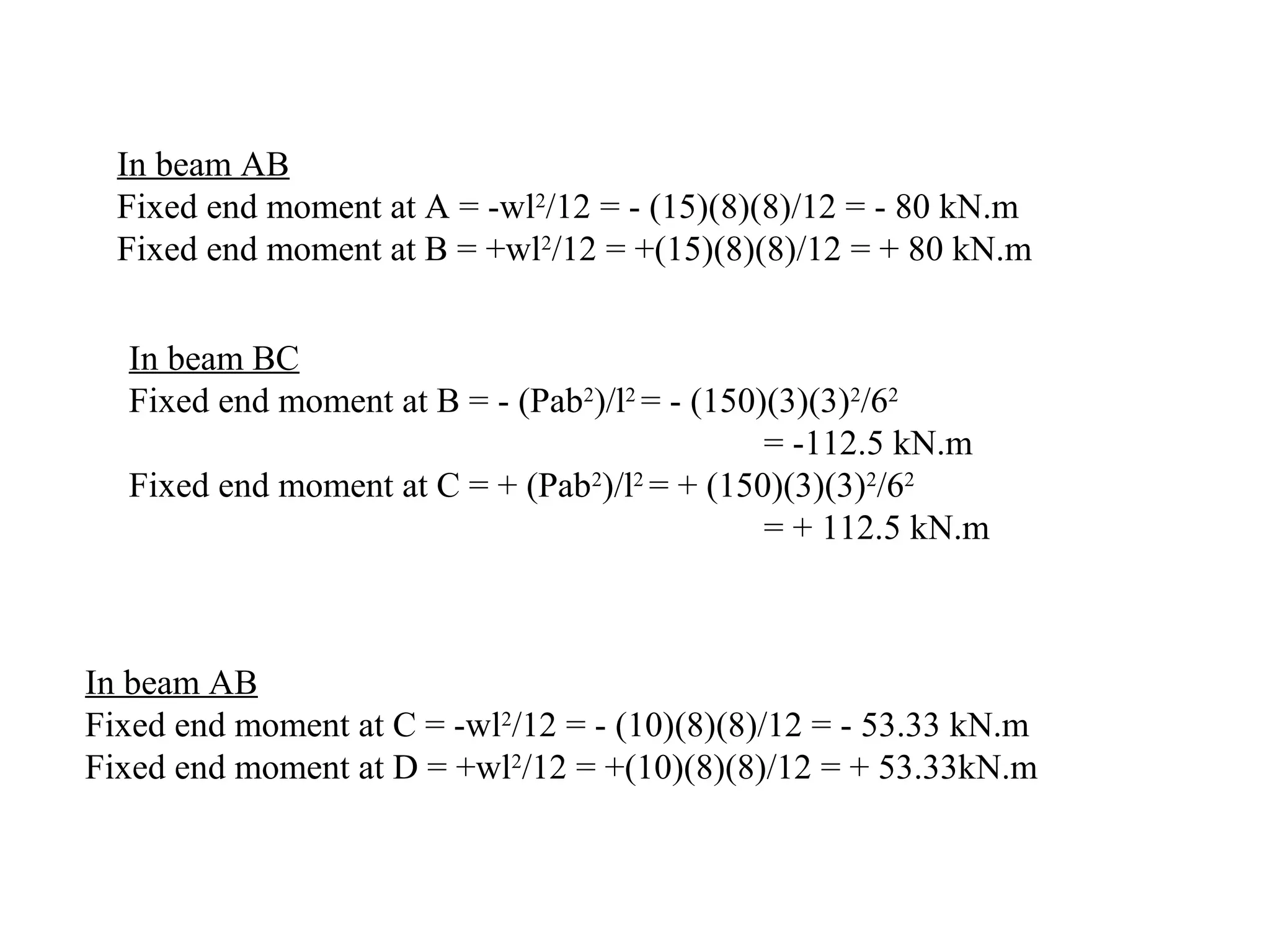

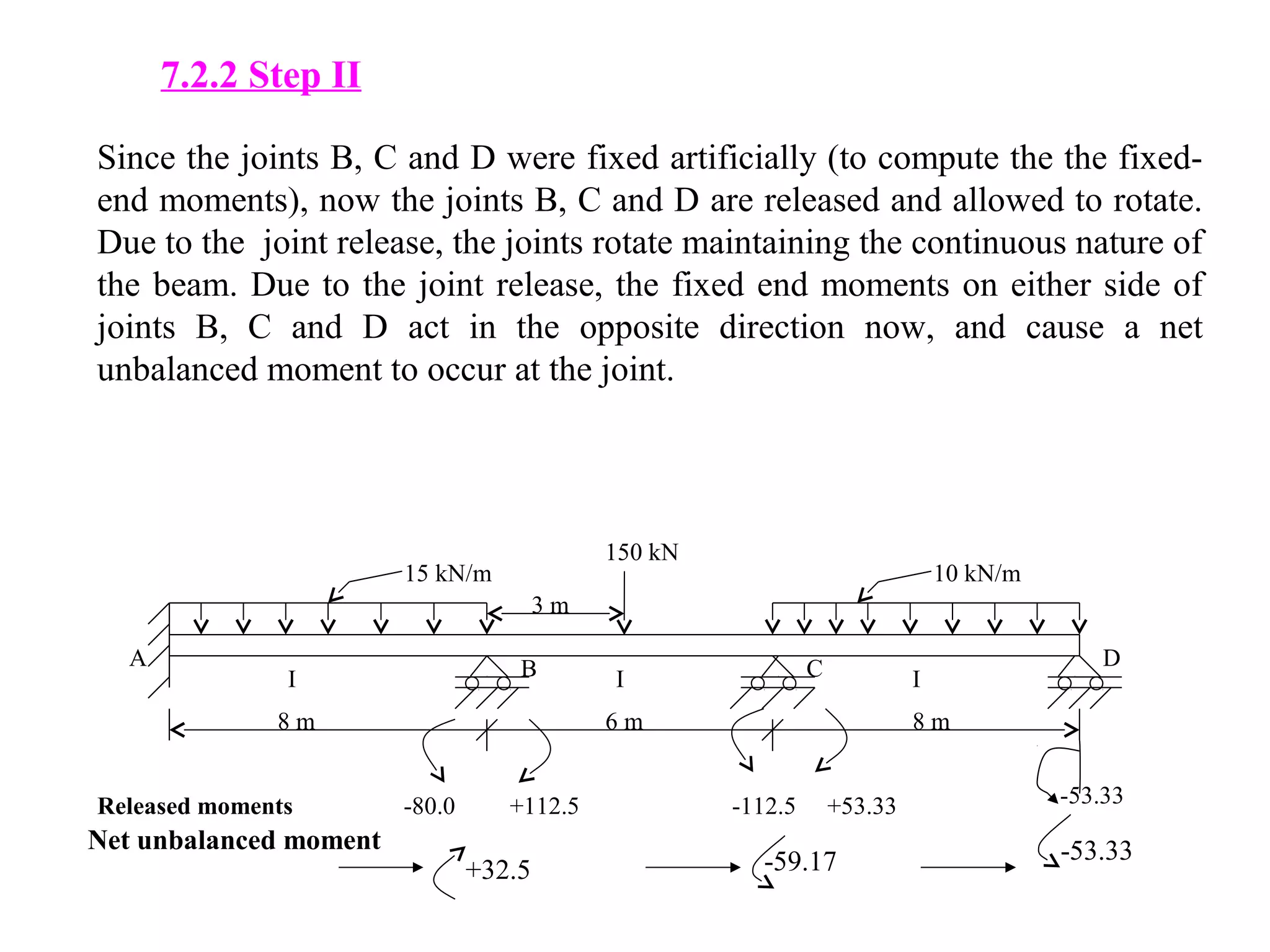

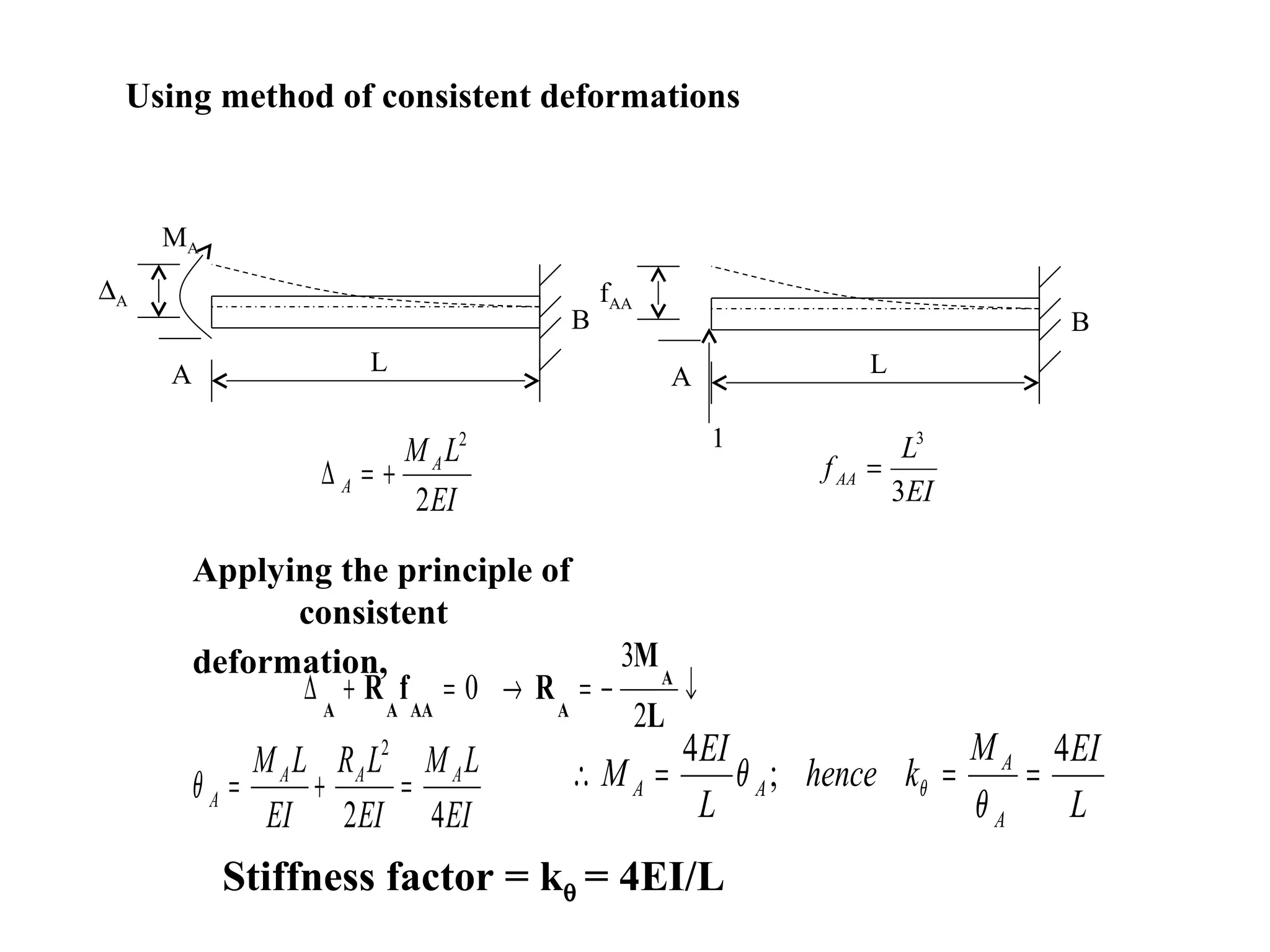

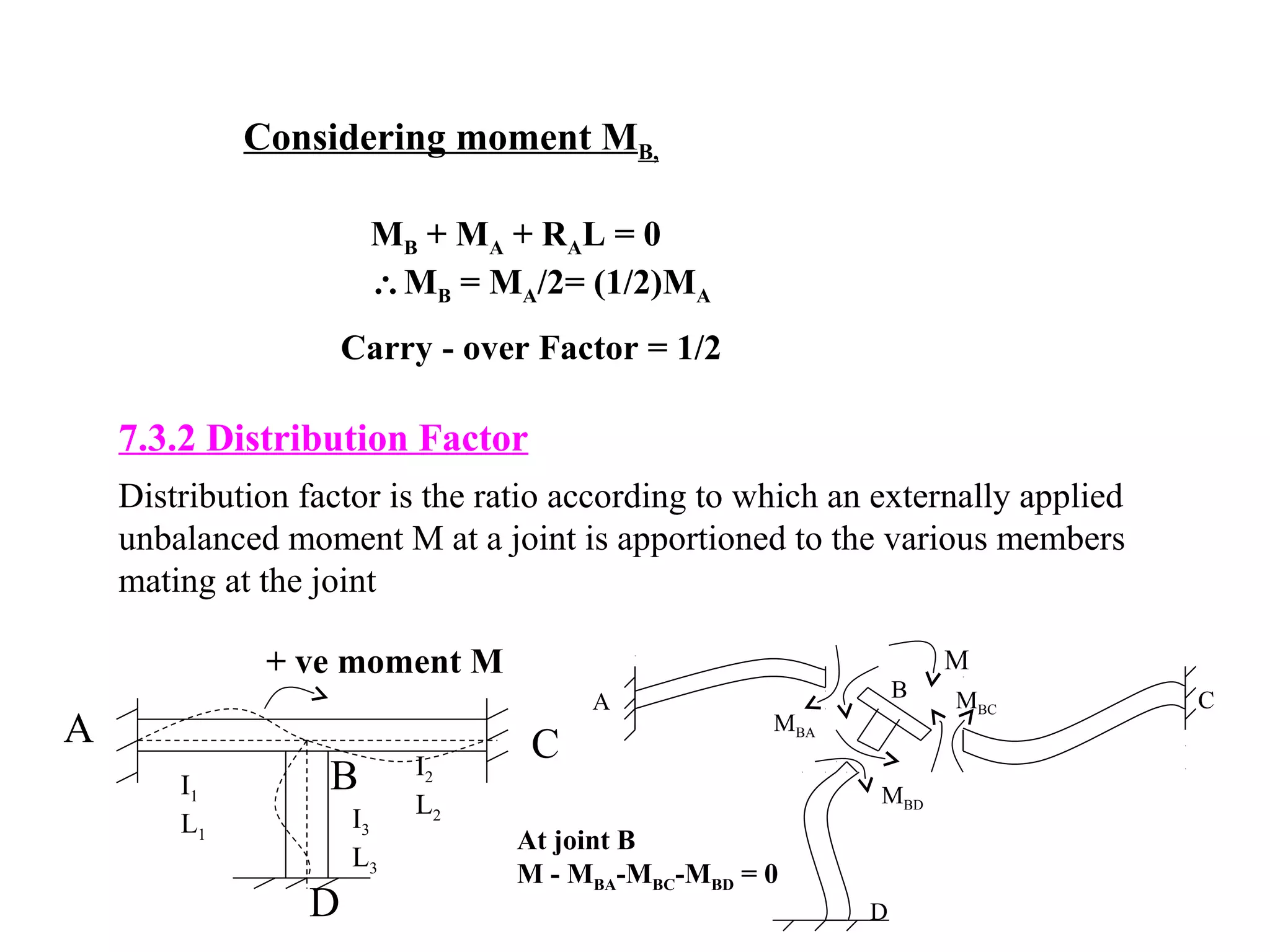

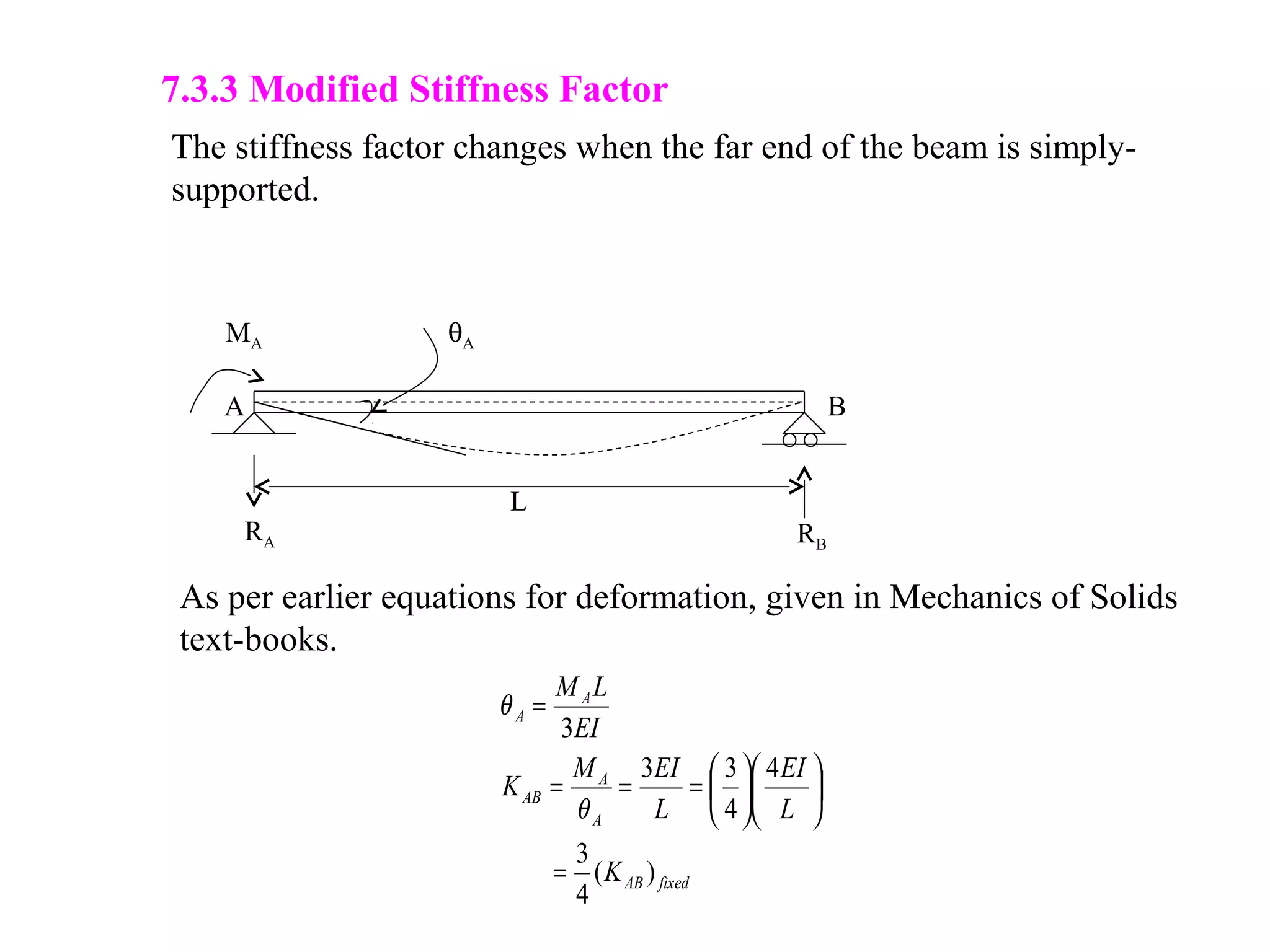

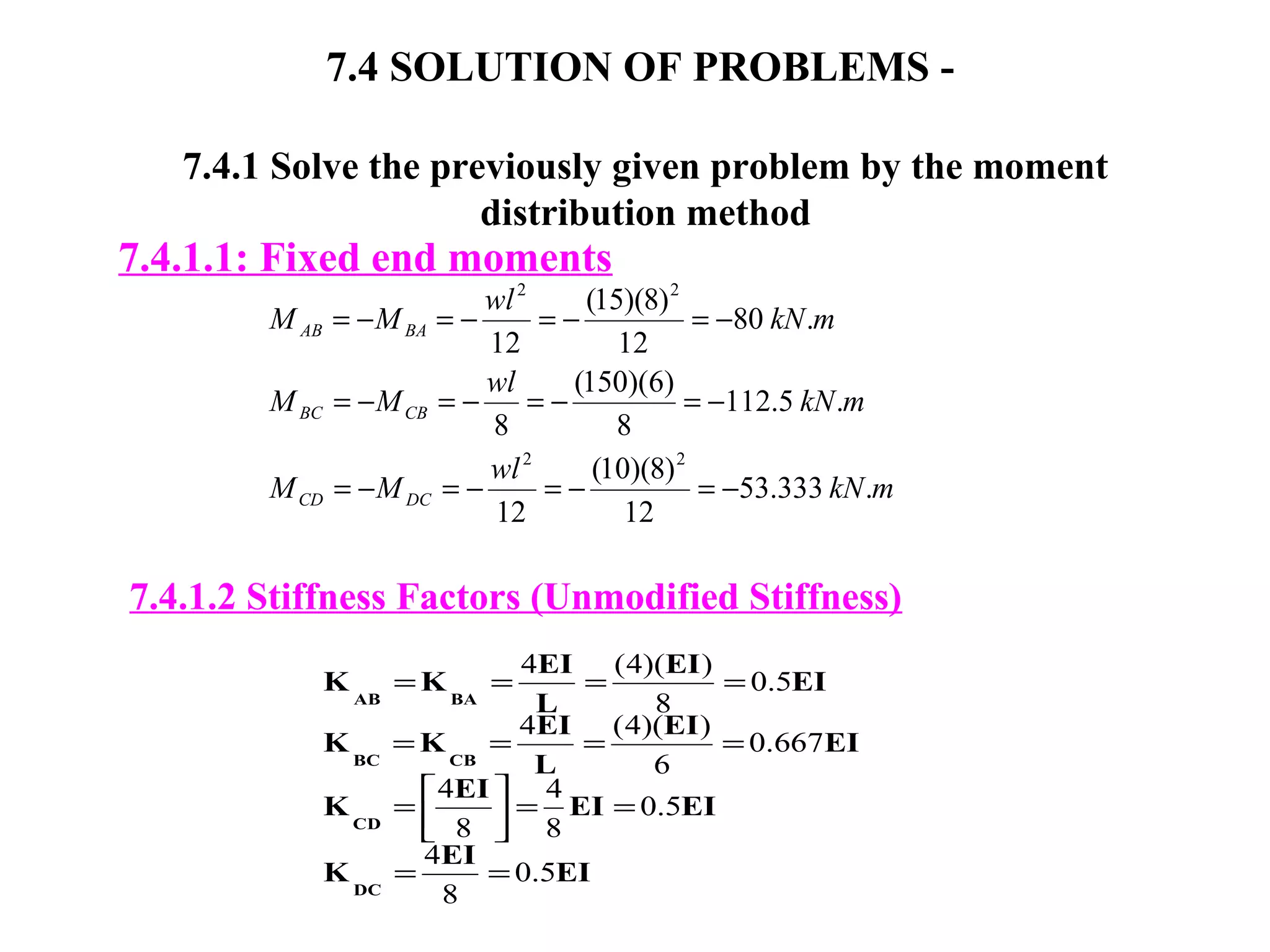

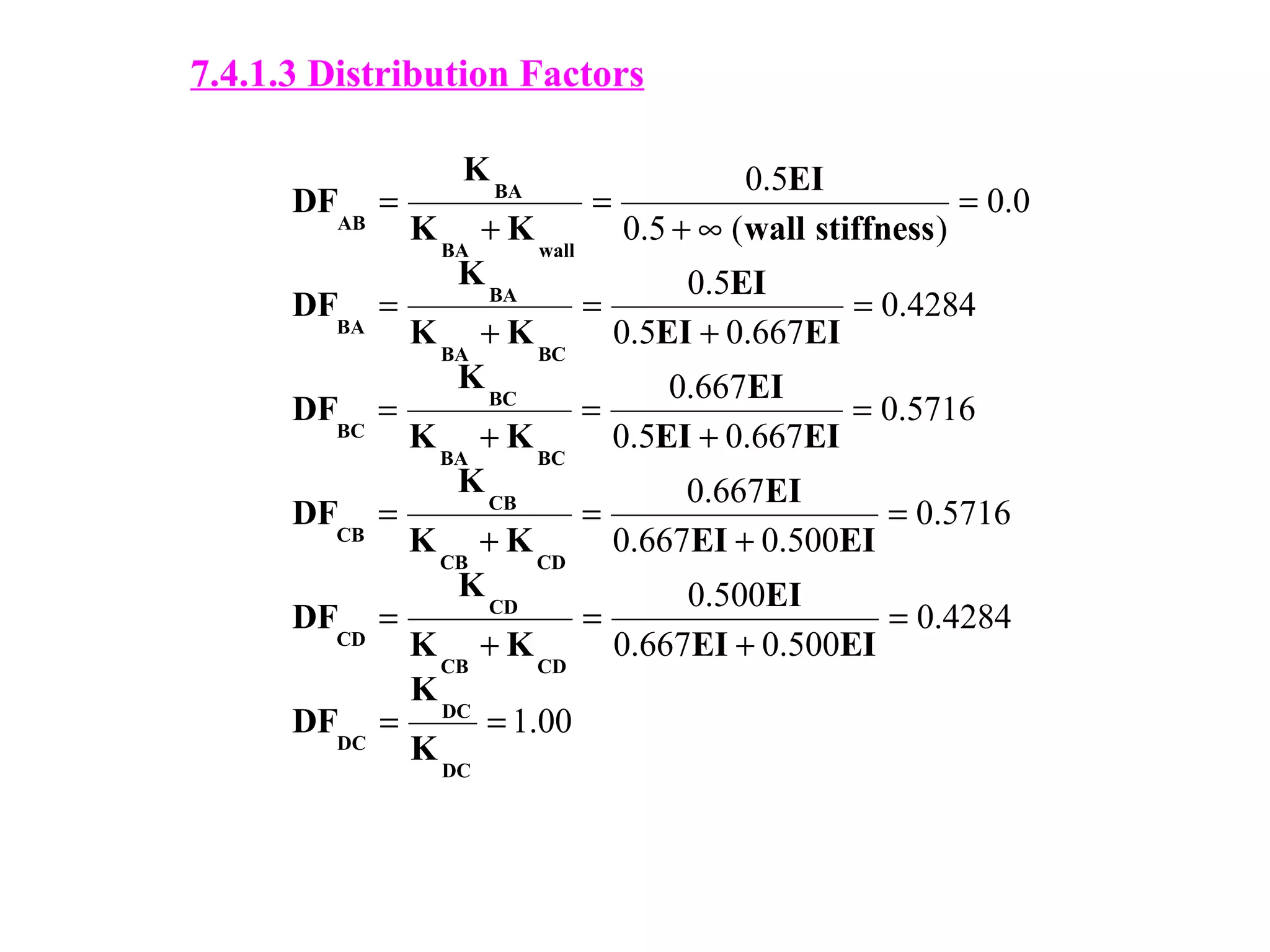

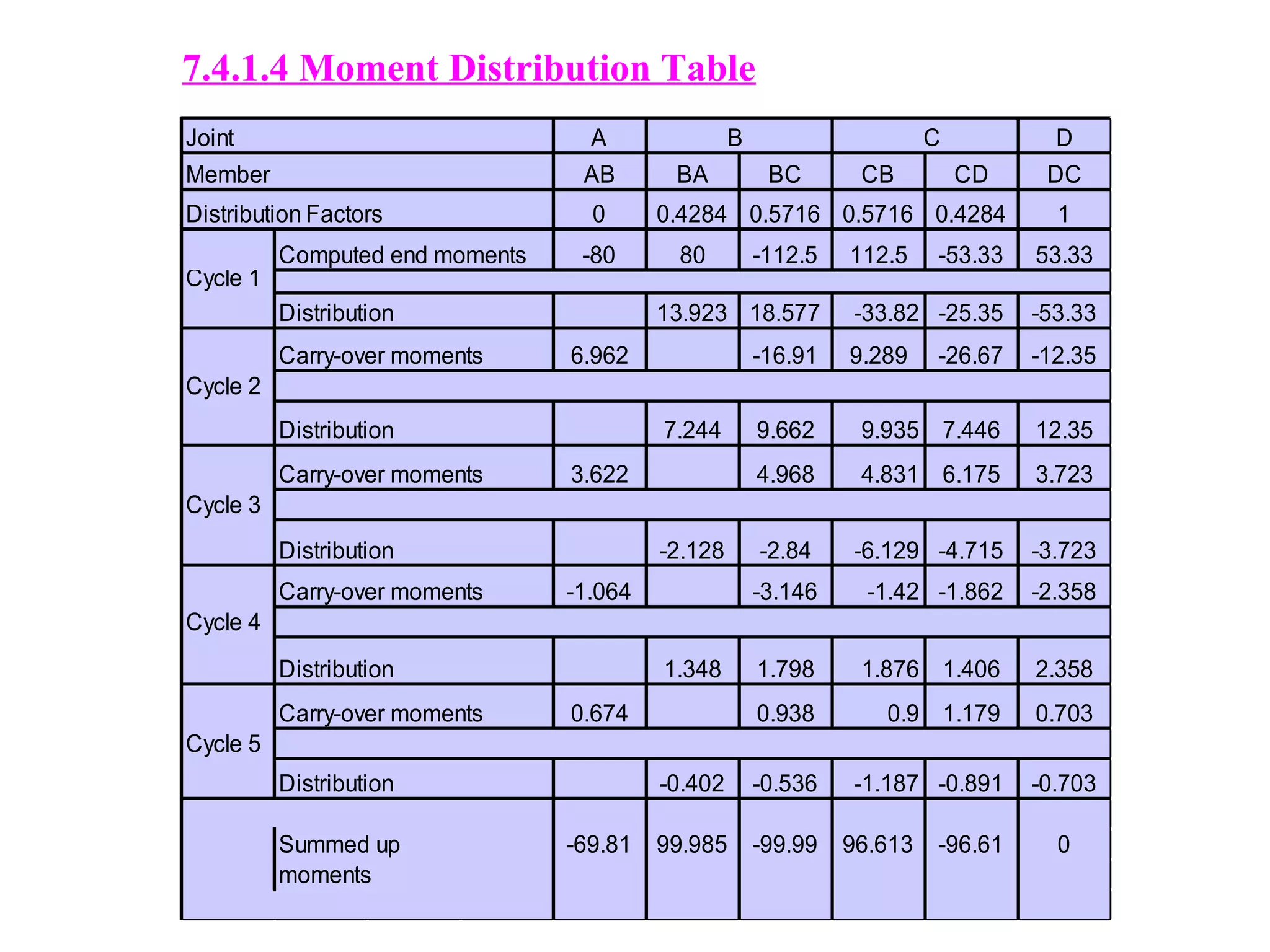

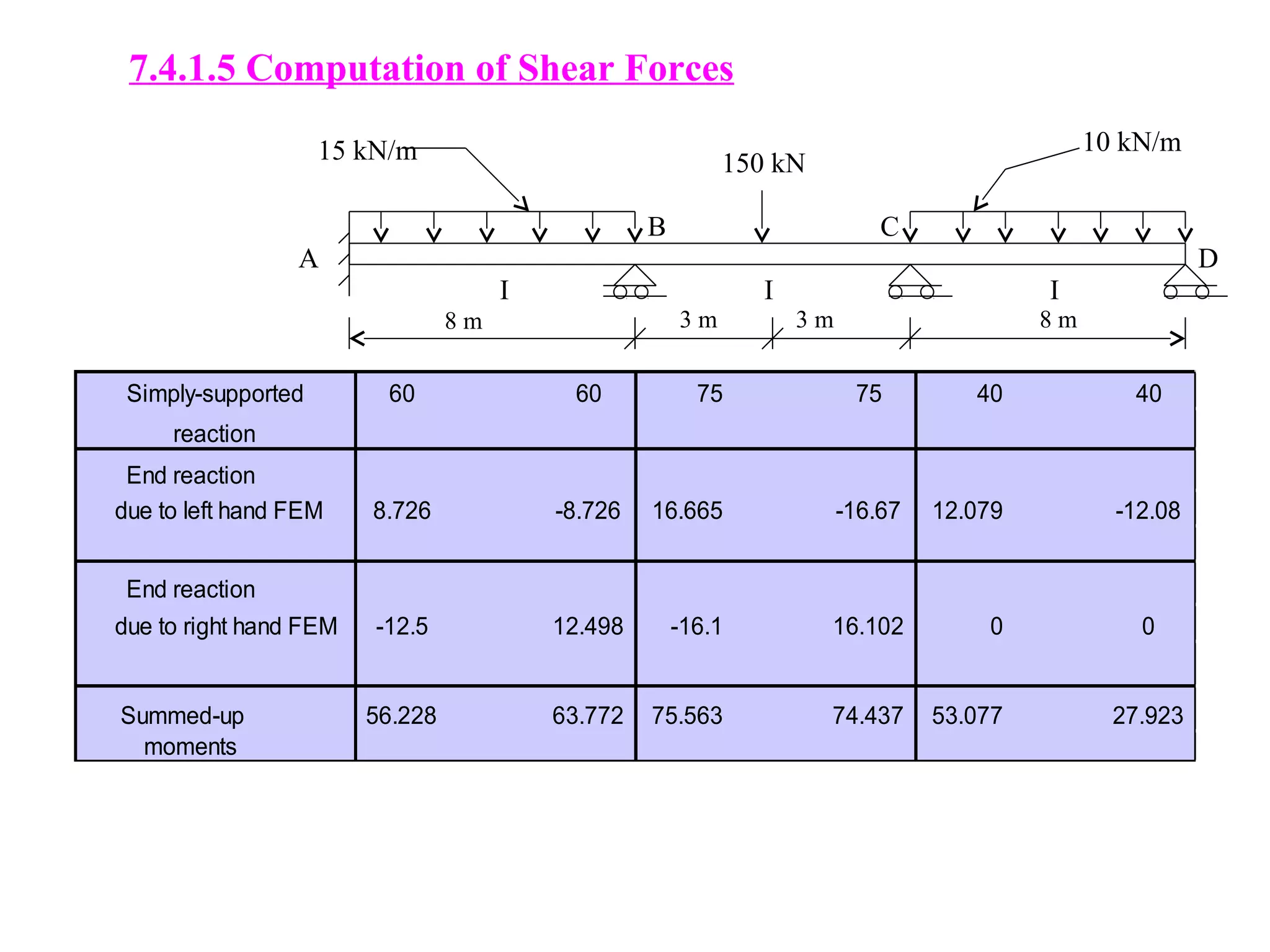

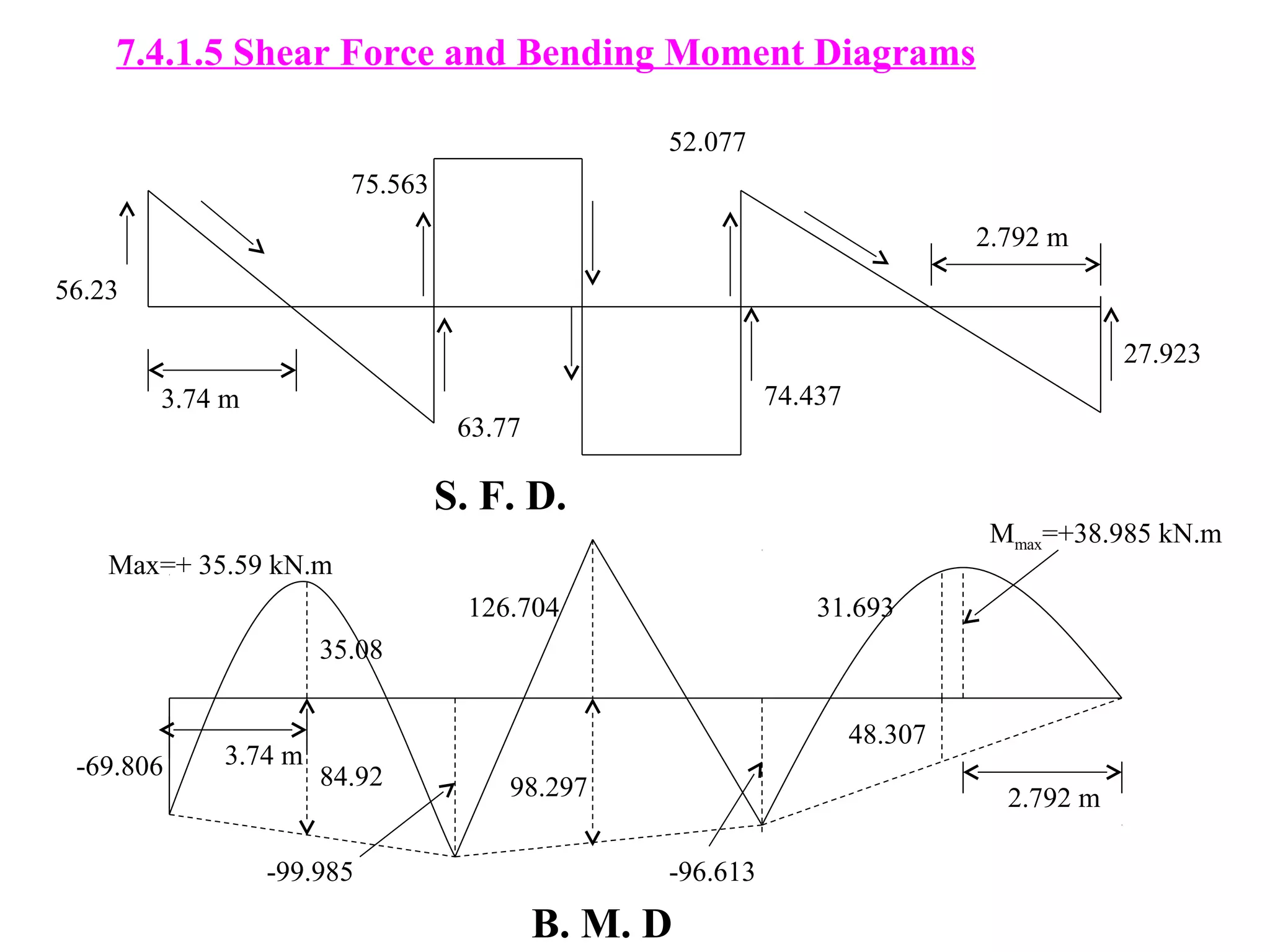

The document discusses the moment distribution method for analyzing statically indeterminate structures. It begins by outlining the basic principles and definitions of the method, including stiffness factors, carry-over factors, and distribution factors. It then provides an example problem, showing the calculation of fixed end moments, establishment of the distribution table through successive approximations, and determination of shear forces and bending moments. Finally, it discusses extensions of the method to structures with non-prismatic members, including using tables to determine necessary values for analysis.