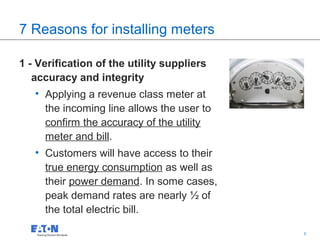

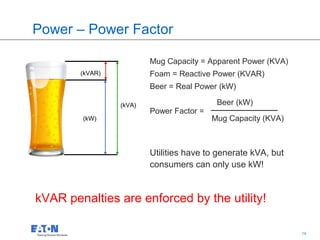

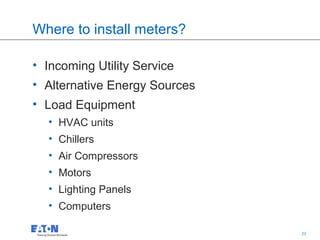

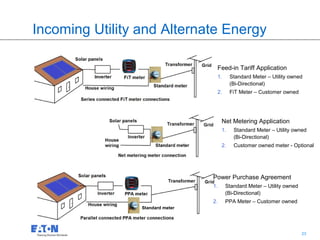

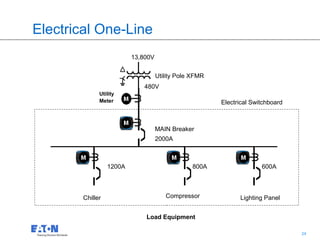

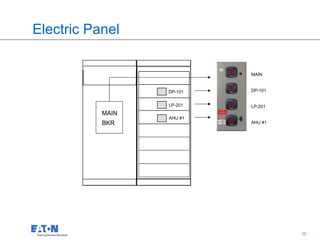

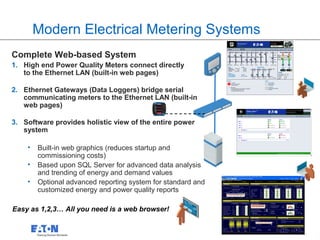

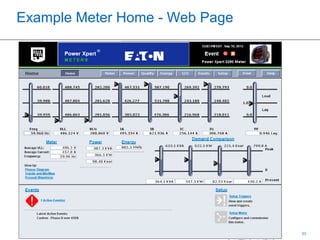

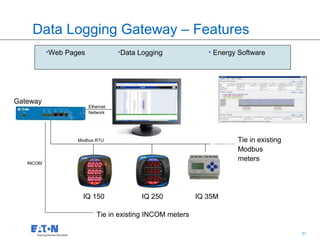

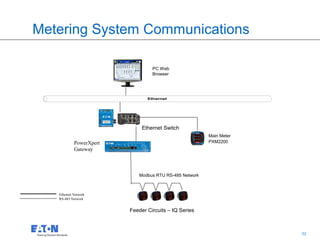

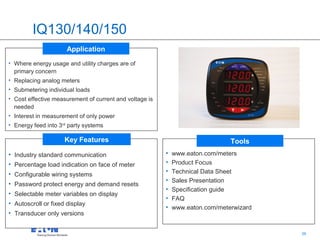

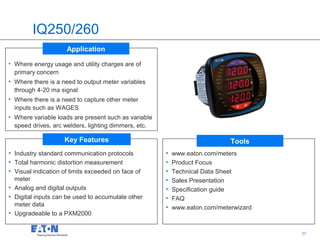

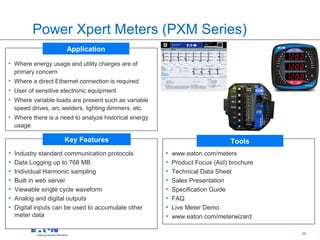

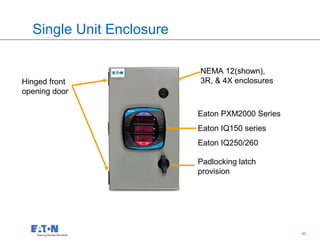

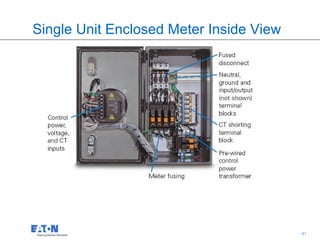

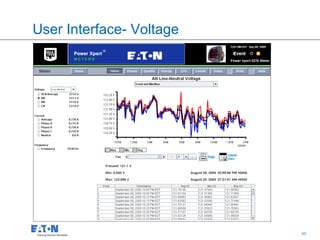

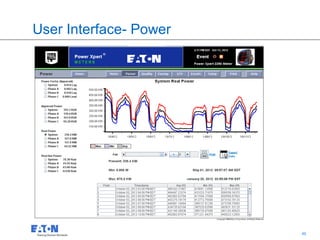

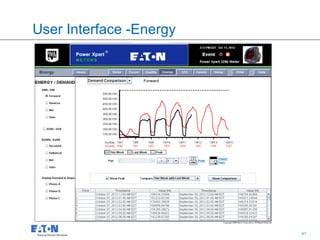

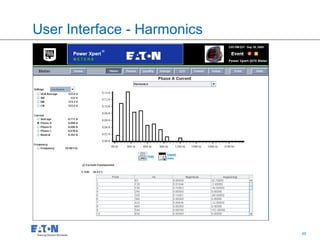

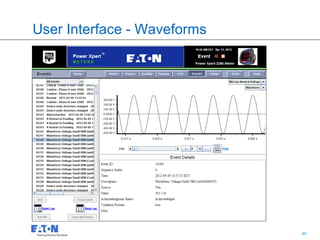

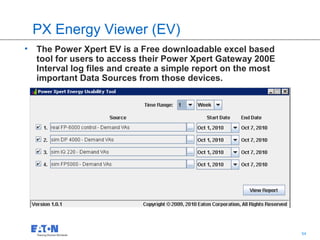

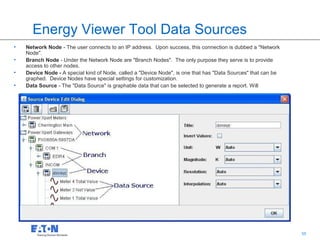

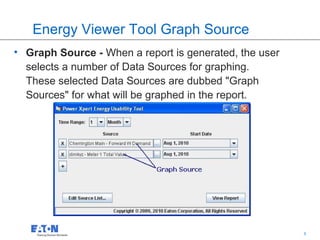

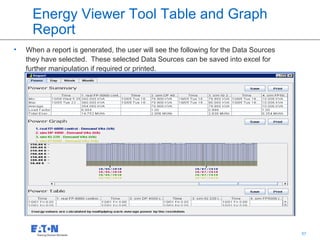

This document provides an overview of electrical metering and monitoring systems. It discusses the importance of metering, what meters measure (energy usage, power demand, power quality issues), and where to install meters (incoming utility service, load equipment, alternative energy sources). It also provides examples of metering solutions, products, and how to understand the data collected by meters. The key information is that meters measure energy usage and power demand, help optimize energy usage, and provide data to understand electrical loads and power quality issues.